Method for testing performance of vehicle door handle and device thereof

A test method and test device technology, which is applied in the direction of measuring device, vehicle test, machine/structural component test, etc., can solve the problem of inability to accurately measure the force and displacement of the handle, the test results cannot provide technical support, Measured value error and other problems, to achieve accurate and intuitive test results, convenient and fast test operation, convenient and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

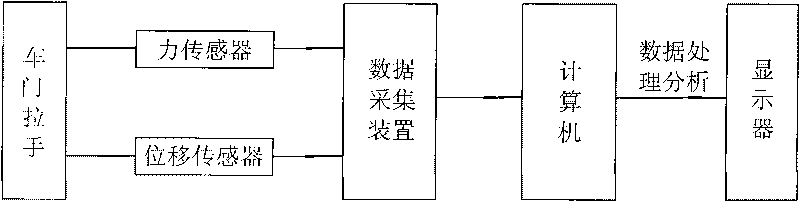

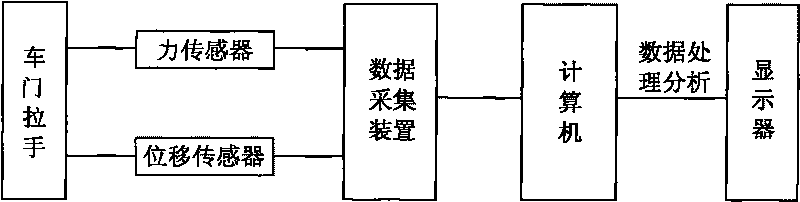

[0014] like figure 1 As shown, the method for testing the performance of the door handle is as follows: through the force sensor 9, the force borne by the handle during the door opening process is sensed in real time and converted into an electrical signal; through the displacement sensor 3, the displacement of the handle during the door opening process is sensed in real time and Convert it into electrical signals, and transmit the two electrical signals to the data acquisition device at the same time. The data acquisition device converts the two collected electrical signals into digital signals and transmits them to the computer for data processing and analysis. After computer processing and analysis, it will be displayed on the display. The real-time relationship coordinate diagram of the force on the handle and the displacement of the handle.

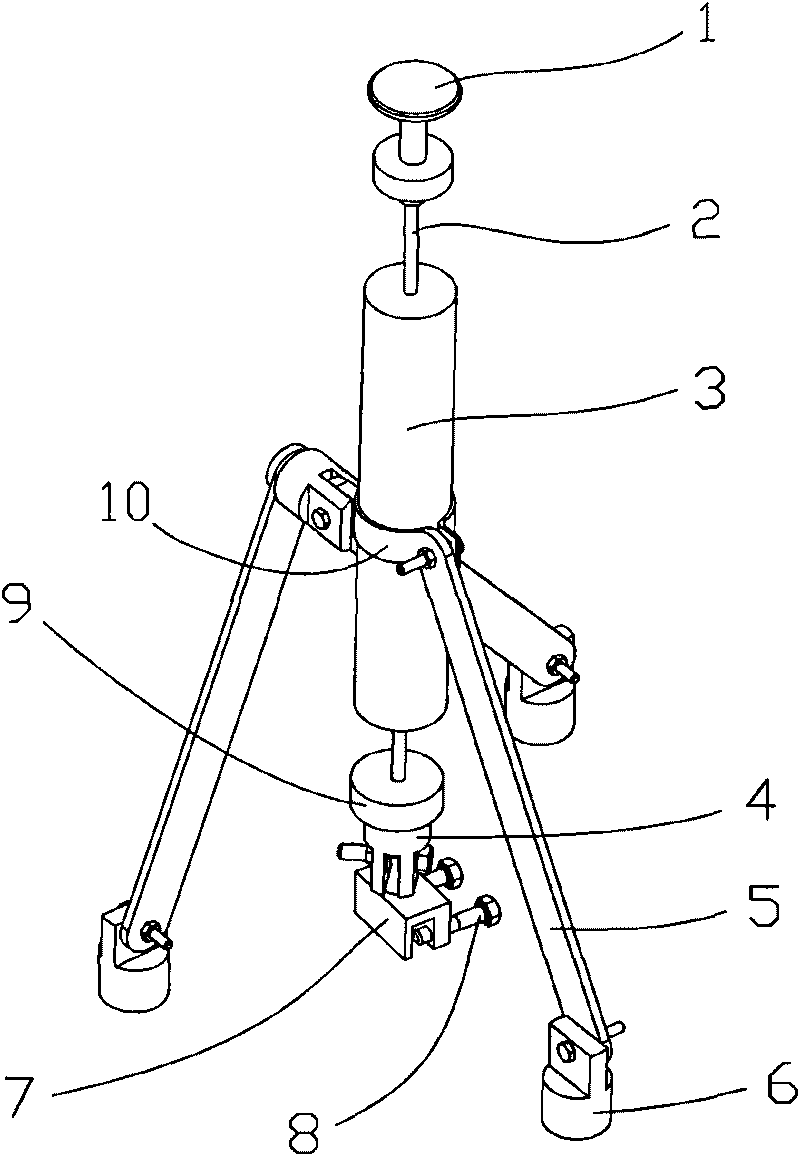

[0015] The door handle performance test device is mainly composed of a force sensor 9, a displacement sensor 3, three support rods ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com