Underground barn with cavity barn wall

A technology for underground granaries and silo walls, applied in climate change adaptation, building types, buildings, etc., can solve the problems of water leakage, detection and repair, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following structural drawings and embodiments further illustrate the present invention.

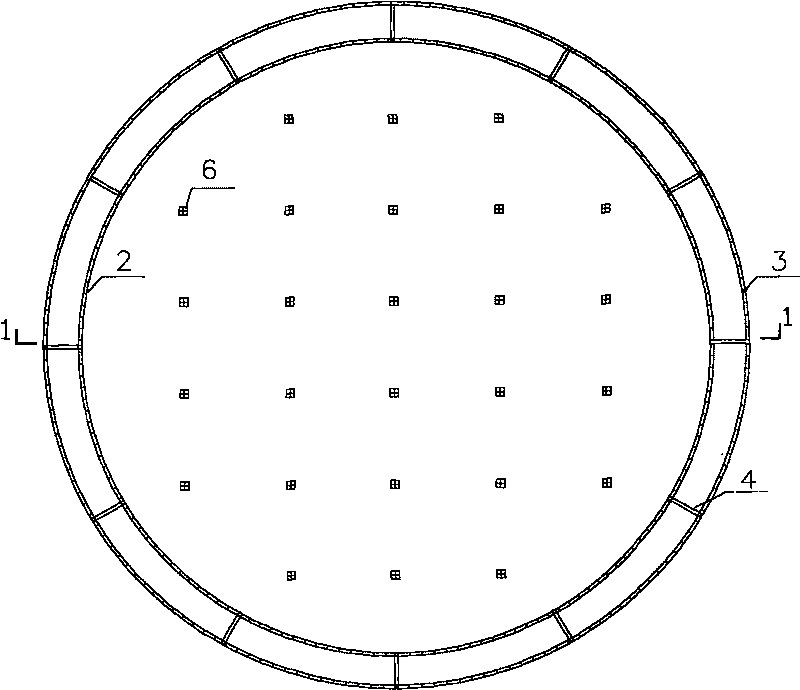

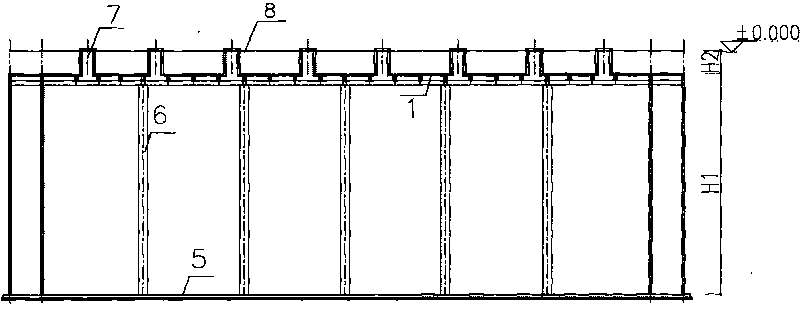

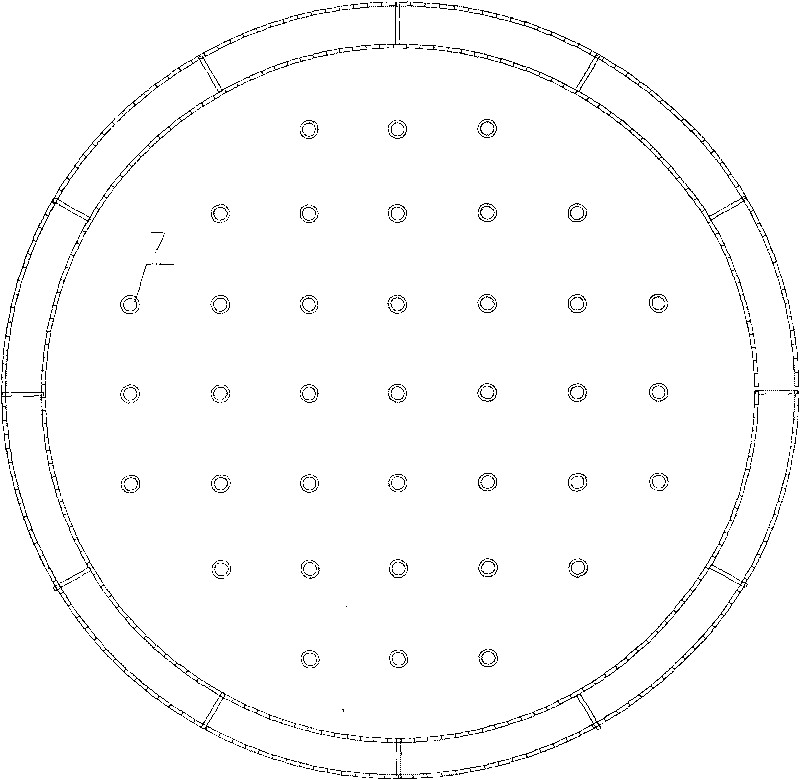

[0020] As shown in the accompanying drawings, the present invention is a circular underground granary with an inner wall 2 diameter of 50 meters and an outer wall 3 diameter of 50.8 meters, including a warehouse top 1, a warehouse wall, and a warehouse bottom 5. The outer walls 3 are connected as a whole by connecting members 4, and a cavity is formed between the inner wall and the outer wall. The inner wall 2 is a cylinder with a diameter of 50 meters, and the outer wall 3 is a cylinder with a diameter of 50.8 meters. The top and bottom of the warehouse are supported by 26 columns 6. The top of the warehouse 1 is provided with a grain inlet and outlet 7. The roof of the warehouse 1 is a beam-slab structure, so that the roof 1 of the warehouse transmits the load to the secondary beam, and then from the secondary beam to the main beam. Pass to pillar 6 by main girder again. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com