Formula of raw materials for producing sulfur microcapsule capable of being used as rubber vulcanizing agent

A microcapsule and sulfur technology, applied in the field of raw material formulation of sulfur microcapsules, can solve the problems of inflammability and explosion, inability to produce rubber products, expensive insoluble sulfur, etc., achieving simple and feasible process, preventing "blooming, and avoiding early vulcanization". effect of the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The quality of each component of the prepared single-shelled sulfur microcapsules is as follows:

[0018] Sublimed Sulfur 14.9g

[0019] Urea 15.1g

[0020] 37% formaldehyde solution 30.1g

[0021] Sodium dodecyl sulfonate 0.15g

[0022] Gelatin 1.5g

[0023] Water 43.6g

[0024] Triethanolamine 0.5g

[0025] Formic acid 0.71g

[0026] The preparation method of single-shell layer sulfur microcapsules is as follows:

[0027] (1) 15.1g of urea and 30.1g of 37% formaldehyde solution were added to the four-necked flask, triethanolamine was added dropwise, the pH value was adjusted to 8-9, and the reaction was stirred at 70° C. for 1h to prepare a urea-formaldehyde resin prepolymer;

[0028] (2) prepare an aqueous solution containing 1.5g of gelatin, add 0.15g of sodium dodecyl sulfonate surfactant, and heat and stir to prepare an aqueous solution;

[0029] (3) sublimation sulfur is added in the aqueous phase solution, with shearing emulsifying machine with 10000rpm ...

Embodiment 2

[0034] The quality of each component of the prepared single-shelled sulfur microcapsules is as follows:

[0035] Sublimed Sulfur 14.9g

[0036] Urea 10.1g

[0037] 37% formaldehyde solution 20.2g

[0038] Sodium dodecyl sulfonate 0.1g

[0039] Gelatin 1.5g

[0040] Water 43.6g

[0041] Triethanolamine 0.5g

[0042] Formic acid 0.71g

[0043] The preparation method of single-shell layer sulfur microcapsules is as follows:

[0044] (1) 10.1g of urea and 20.2g of 37% formaldehyde solution were added to the four-necked flask, 0.5g of triethanolamine was added dropwise, the pH value was adjusted to 8-9, and the reaction was stirred at 70° C. for 1h to prepare a urea-formaldehyde resin prepolymer;

[0045] (2) prepare an aqueous solution containing 1.5g of gelatin, add 0.1g of sodium dodecyl sulfobenzene surfactant, and heat and stir to prepare an aqueous solution;

[0046] (3) sublimation sulphur is added in the aqueous phase solution, with shear emulsifying machine with 10...

Embodiment 3

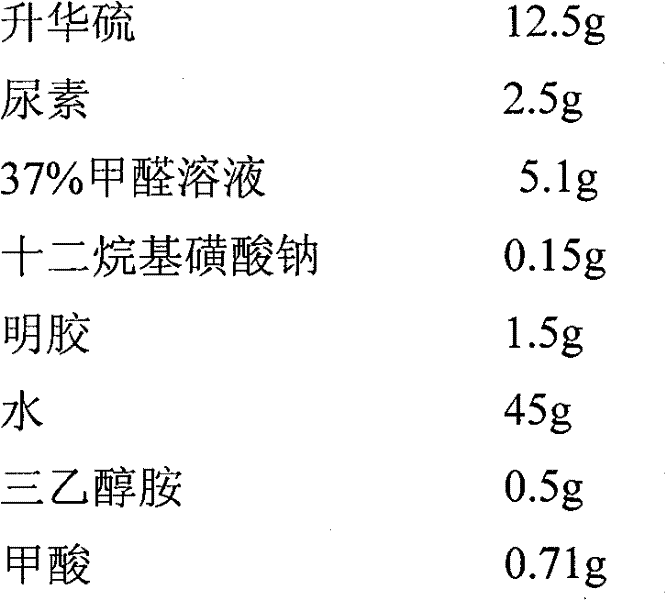

[0051] The quality of each component of the prepared single-shelled sulfur microcapsules is as follows:

[0052] Sublimed Sulfur 15g

[0053] Urea 5.0g

[0054] 37% formaldehyde solution 9.9g

[0055] Sodium dodecyl sulfonate 0.15g

[0056] Gelatin 1.5g

[0057] water 45g

[0058] Triethanolamine 0.5g

[0059] Formic acid 0.71g

[0060] The preparation method of single-shell layer sulfur microcapsules is as follows:

[0061] (1) 5g of urea and 9.9g of 37% formaldehyde solution were added to the four-necked flask, 0.5g of triethanolamine was added dropwise, the pH value was adjusted to 8-9, and the reaction was stirred at 70° C. for 1h to prepare a urea-formaldehyde resin prepolymer;

[0062] (2) prepare an aqueous solution containing 1.5g of gelatin, add 0.15g of sodium dodecyl sulfobenzene surfactant, and heat and stir to prepare an aqueous solution;

[0063](3) sublimation sulphur is added in the aqueous phase solution, with shear emulsifying machine with 10000rpm ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com