Automobile lubricant

A technology of lubricating oil and lubricating oil for vehicles, which is applied in the field of lubricating oil, can solve problems such as unsatisfactory products and no lubricating oil solution, and achieve moderate viscosity, obvious technical effects, and wide range of technical applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Prepare vehicle lubricating oil according to the composition in Table 2, mix and stir according to the technical requirements of the blending process of internal combustion engine oil to obtain the lubricating oil of each batch number in Table 2.

[0025] Table 2

[0026] batch number

SL5W-30

(weight%)

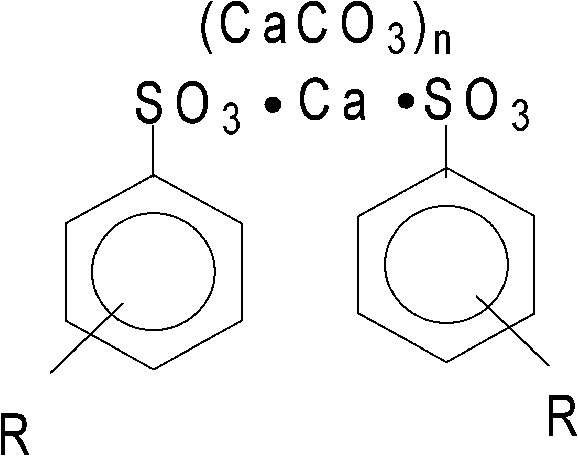

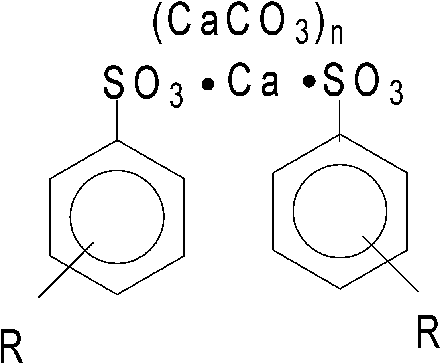

High base value calcium sulfonate

(weight%)

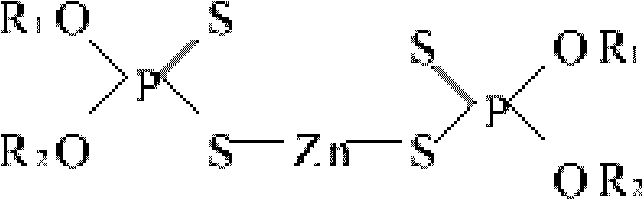

Zinc Dialkyl Dithiophosphate

(weight%)

20040315-343

100

0.30

0.25

20040525-343

100

0.35

0.21

20040623-343

100

0.34

0.24

200803010343

100

0.35

0.23

200805140343

100

0.36

0.23

2008012140345

100

0.38

0.22

200903180345

100

0.37

0.23

200906070342

100

0.39

0.20

[0027] The four-ball extreme pressure anti-wear test was carried out on the lubricating oil of each batch according to the test methods PSA D55 1136 and PSA D55 1078 in Table 1, and...

Embodiment 2

[0033] Prepare lubricating oil for vehicles according to the composition in Table 4, mix and stir to obtain the lubricating oil of each batch number in Table 4 according to the technical requirements of the blending process of internal combustion engine oil.

[0034] Table 4

[0035] batch number

SJ10W-40

(weight%)

High base value calcium sulfonate

(weight%)

Zinc Dialkyl Dithiophosphate

(weight%)

20040114-343

100

0.30

0.25

20040217-343

100

0.35

0.21

20040320-343

100

0.34

0.24

200803010307

100

0.36

0.20

200805120307

100

0.35

0.23

200809250304

100

0.33

0.22

200904020309

100

0.37

0.23

200906110309

100

0.39

0.26

[0036] The four-ball extreme pressure anti-wear test was carried out on the lubricating oil of each batch number in Table 4 according to the test methods PSA D55 1136 and PSA D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com