Protective film reposting device and method

A protective film, re-sticking technology, applied in lamination devices, chemical instruments and methods, lamination auxiliary operations, etc., can solve problems such as poor appearance, affecting the effect of protective film, affecting the production accuracy and product quality of polarizers, and achieving The effect of improving production efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

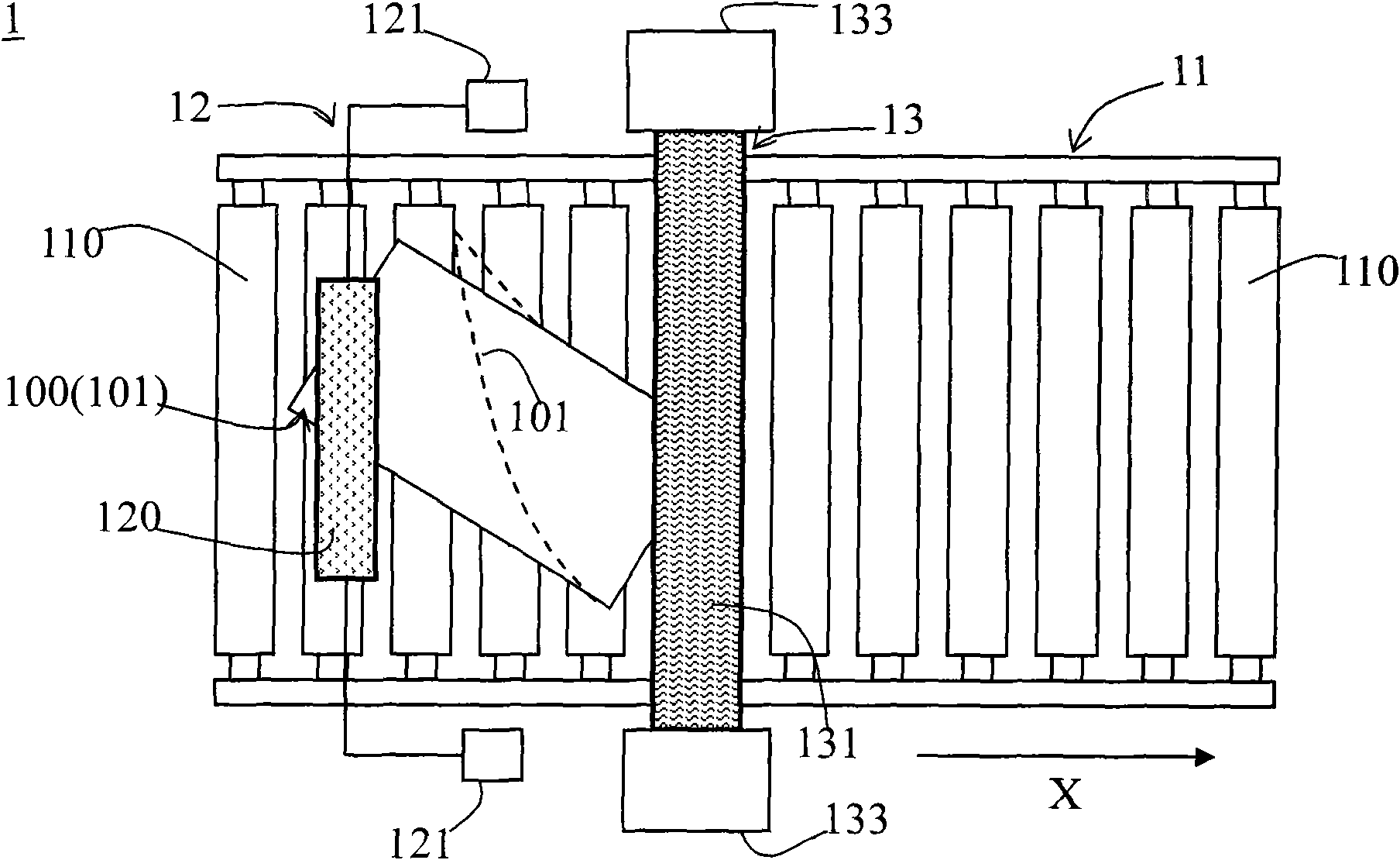

[0020] See figure 1 , figure 1 It is a schematic diagram of a protective film reapplying device 1 according to an embodiment of the present invention. The protective film reapplying device 1 is used for partially peeling off the protective film 101 on the optical sheet 100 and then reattaching it to the optical sheet.

[0021] The conveying mechanism 11 includes a plurality of conveying rollers 110 arranged side by side for driving the optical sheet 100 to move in the first direction X.

[0022] The peeling mechanism 12 is disposed above the conveying mechanism 11 for partially peeling the protective film 101 from the optical sheet 100 . In one implementation, the peeling mechanism 12 includes an adhesive roller 120 for adhering and peeling the protective film 101 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com