Manufacture method of eccentric cone shell

A technology of an eccentric cone shell and a manufacturing method, which is applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of high labor intensity, huge investment, labor-intensive and time-consuming, etc., and achieves low labor intensity, reduced investment, and strong versatility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

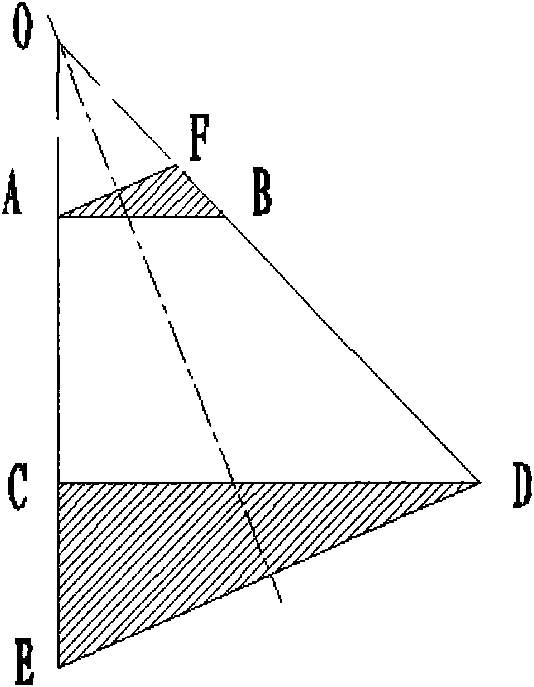

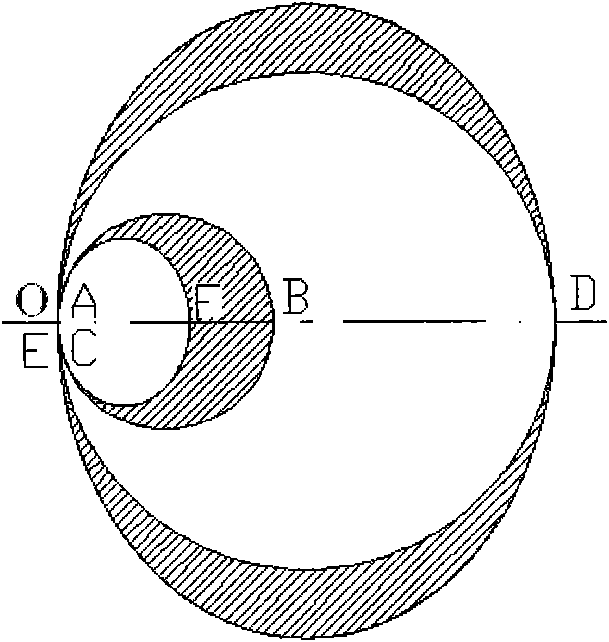

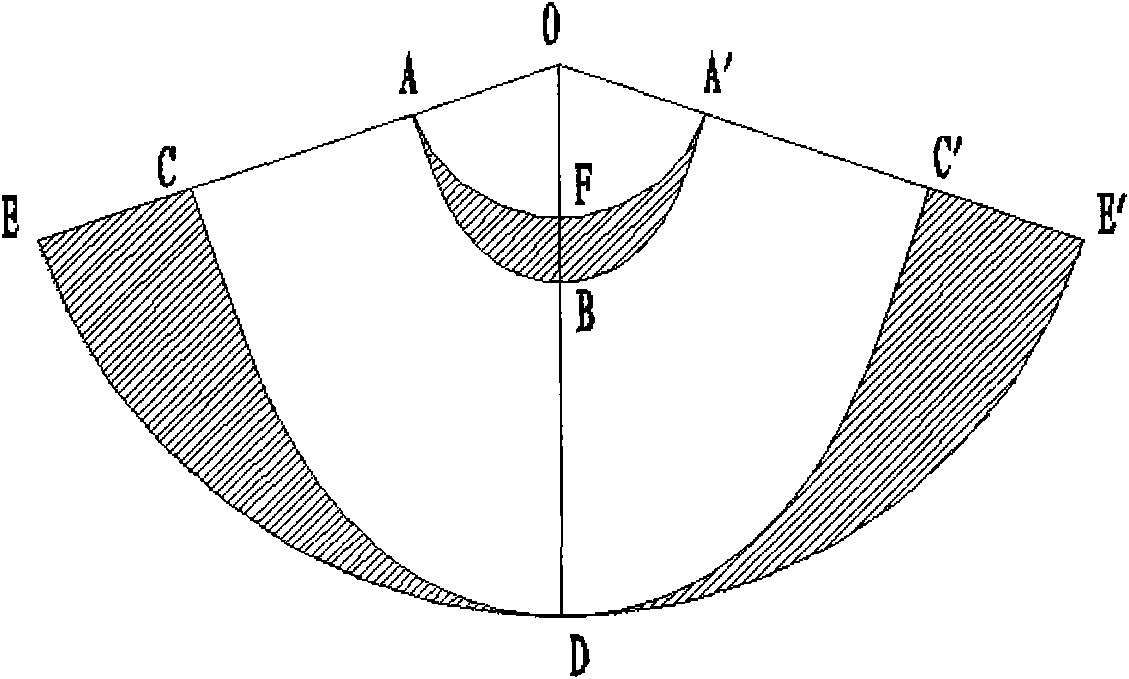

[0026] The present invention utilizes three-roll plate rolling machine to roll out AFDC ( figure 1 , figure 2 , the AFDE shown is a positive conical shell and image 3 The shown AFA'E'DE is a forward conical shell expansion diagram); at this time, the large end surface of the conical shell is an ellipse, and the sample is measured by the inner arc of the large end, as Figure 4 As shown, the conical shell is corrected on the three-roll plate rolling machine, so that the large end face is corrected as a circular end face; after the correction, the AFB part is cut off to obtain the eccentric cone shell ABDC.

[0027] The invention is applicable to eccentric conical shells with different angles.

[0028] The specific implementation steps of the present invention are as follows:

[0029] (1) Draw the front view according to the size of the neutral layer of the eccentric conical shell to be manufactured, namely figure 1 In the ABDC section. It is also possible to draw its top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com