Tooth-bleaching material and method of bleaching tooth

A tooth and tooth surface technology, applied in the field of bleaching materials, can solve the problems of simplicity and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9

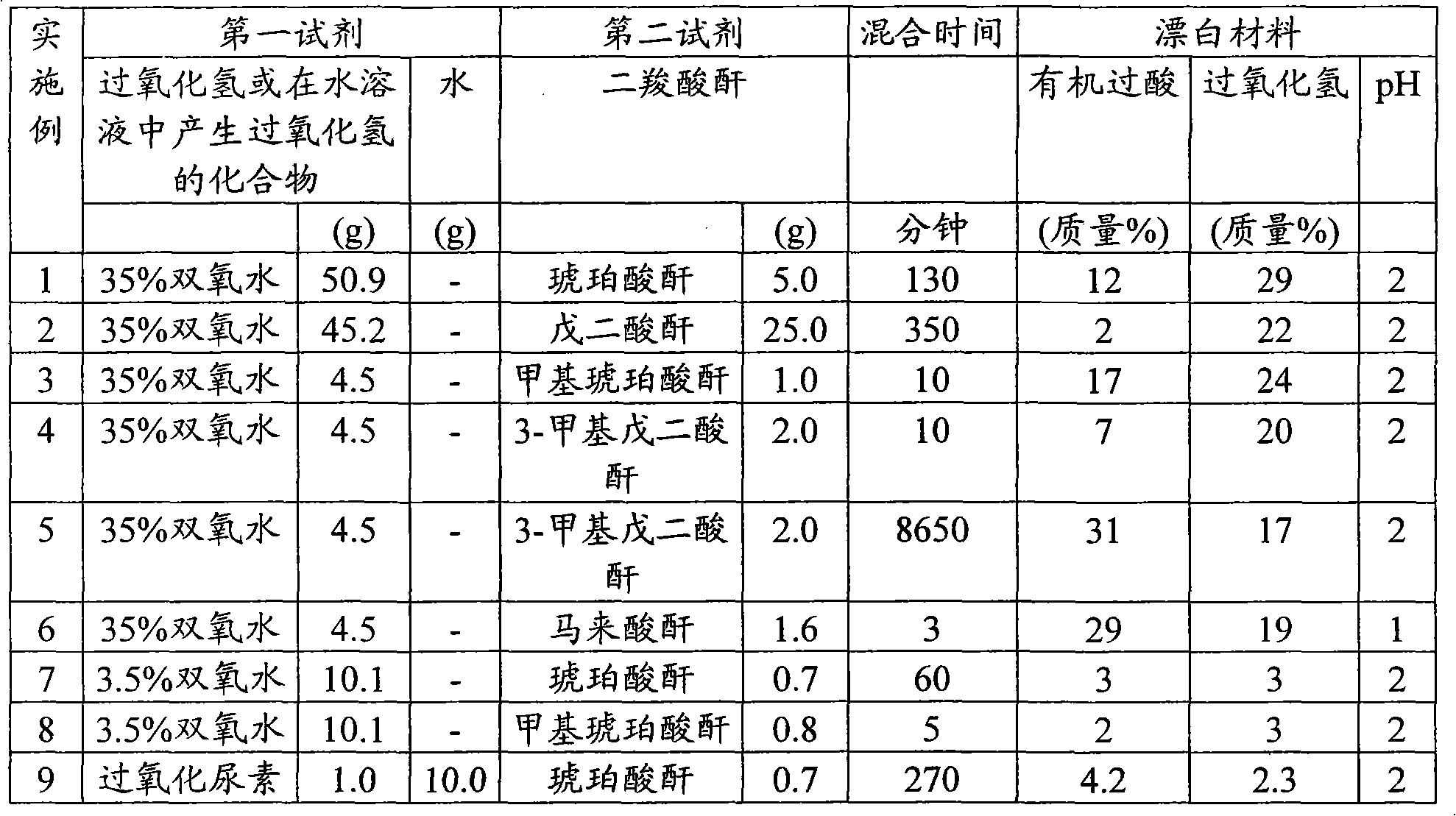

[0027] The second reagent was added to the first reagent shown in Table 1, and mixed for a certain period of time to obtain tooth bleaching materials prepared separately.

[0028] Table 1

[0029]

Embodiment 10

[0031] The tooth bleaching material obtained in Example 3 was diluted with purified water, and the pH was adjusted with NaOH to obtain tooth bleaching with a total active oxygen content of 1.3% (1.8% by mass of peroxymethylsuccinic acid, 2.3% by mass of hydrogen peroxide) and a pH of 5. Material.

Embodiment 11

[0033] The pH of the tooth bleaching material obtained in Example 7 was adjusted with NaOH aqueous solution to obtain a tooth bleaching material with a total active oxygen content of 1.1% (peroxysuccinic acid 1.9% by mass, hydrogen peroxide 1.9% by mass) and a pH of 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com