Dual cell body side rail for automotive vehicles

A technology for motor vehicles and unit vehicles, applied in vehicle components, load-bearing body structures, superstructure sub-assemblies, etc., to solve problems such as excess weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

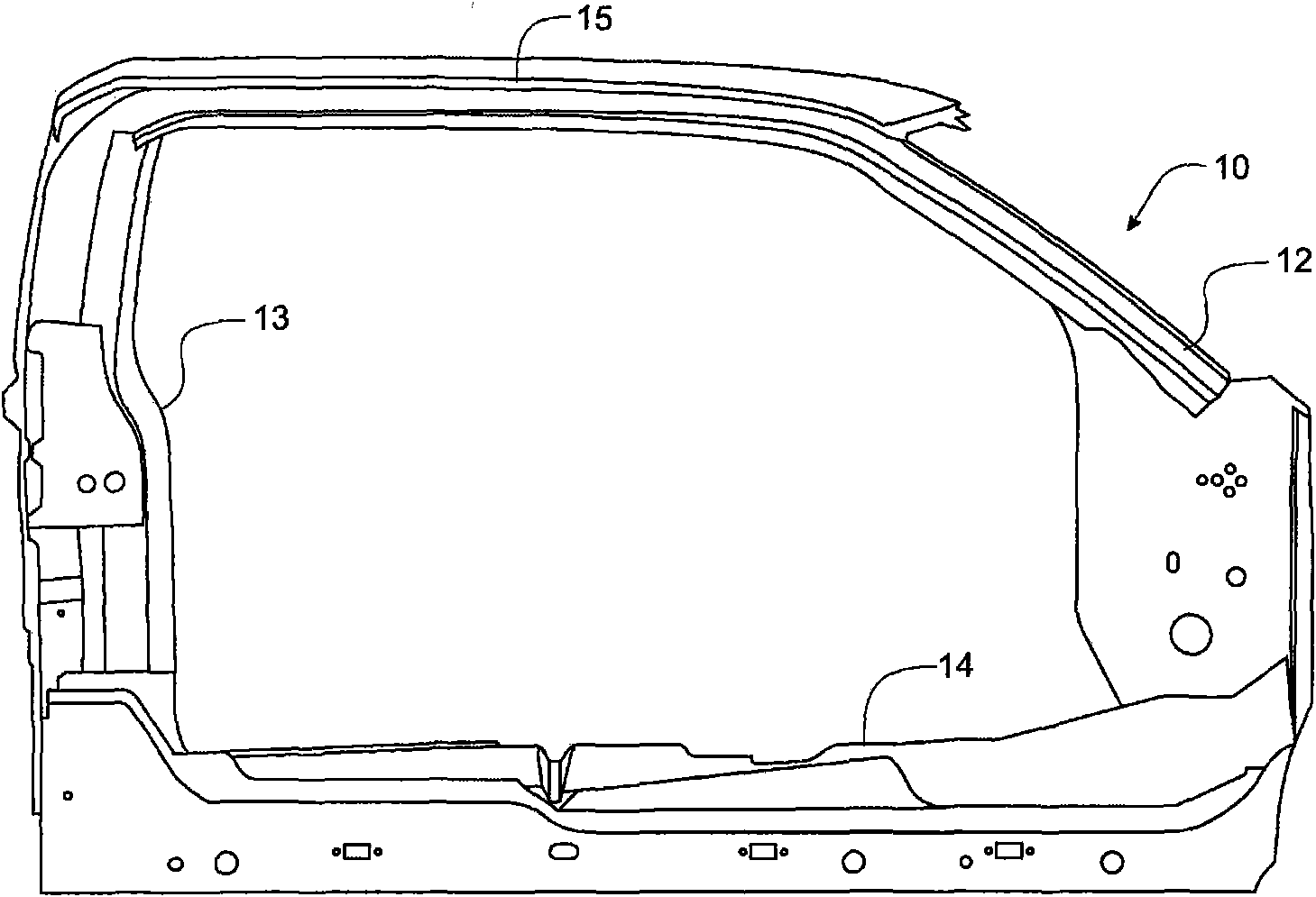

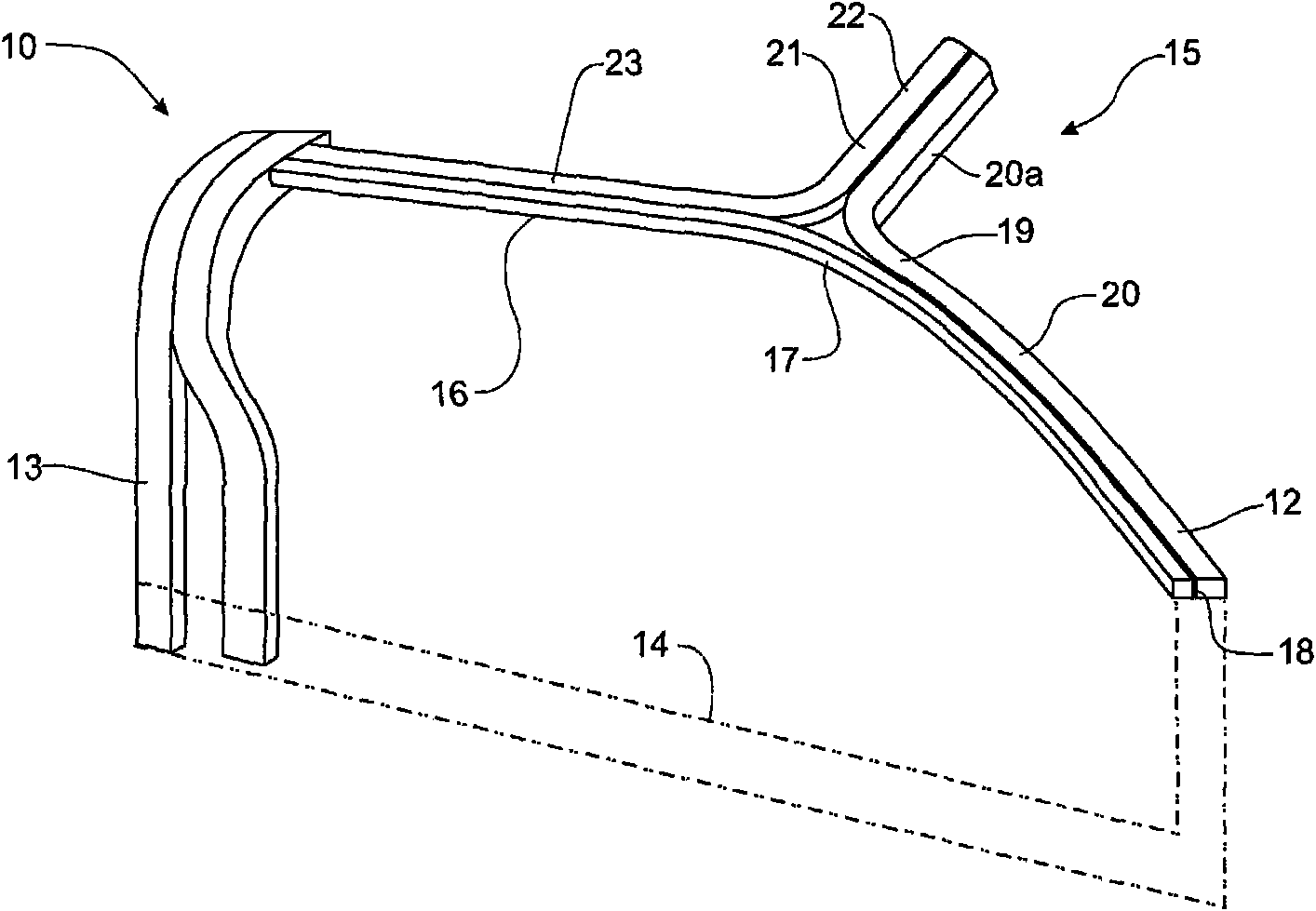

[0026] Referring to the drawings, there can be seen a body side frame structure for a cab of a motor vehicle such as an open pickup truck. For convenience, a left or right reference mark is used, which is determined by standing at the rear of the vehicle, facing the normal direction of forward travel of the vehicle. The body side frame structure 10 includes a front pillar 12 , a rear corner pillar 13 , and a roof rail structure 15 extending between said front and rear pillars 12 , 13 . The frame 10 of the cab is formed with a substantially vertical front pillar (or "A-pillar") 12 extending between a floor member 14 and a roof structure 15 . The rear pillar 13 makes the vehicle body side frame structure 10 substantially form a rectangular structure, and the rear pillar 13 is used for mounting front and rear doors (not shown) through hinges (not shown). Normally, the front doors are hinged on the front A-pillar 12, while the rear B-pillar can support the hinges for the rear doo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com