Device for preventing redundant robot wiring from winding and extruding

A extrusion device and robot technology, applied in manipulators, manufacturing tools, etc., can solve problems such as hindering the normal use of robots, mutual extrusion, and easy entanglement of cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

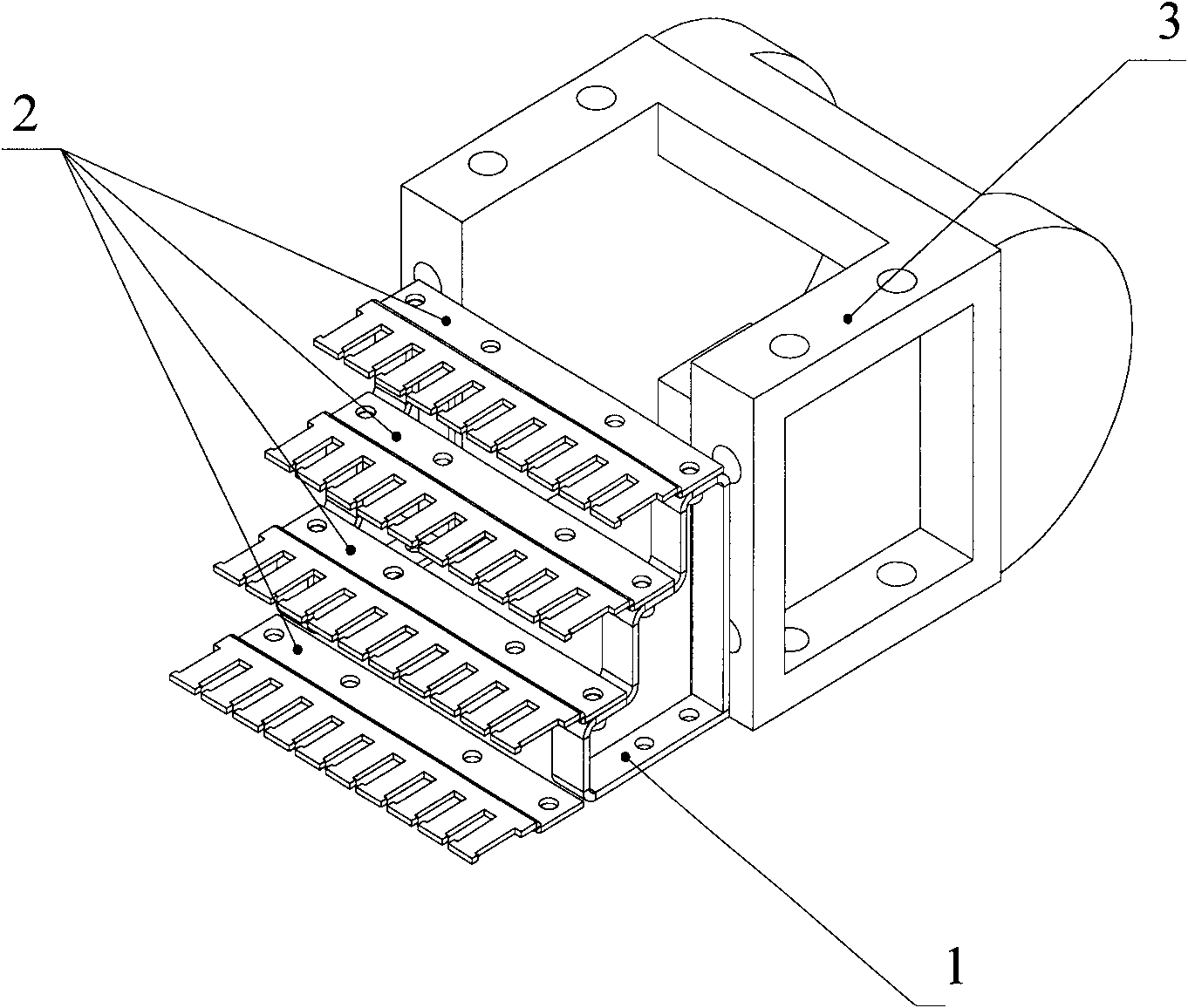

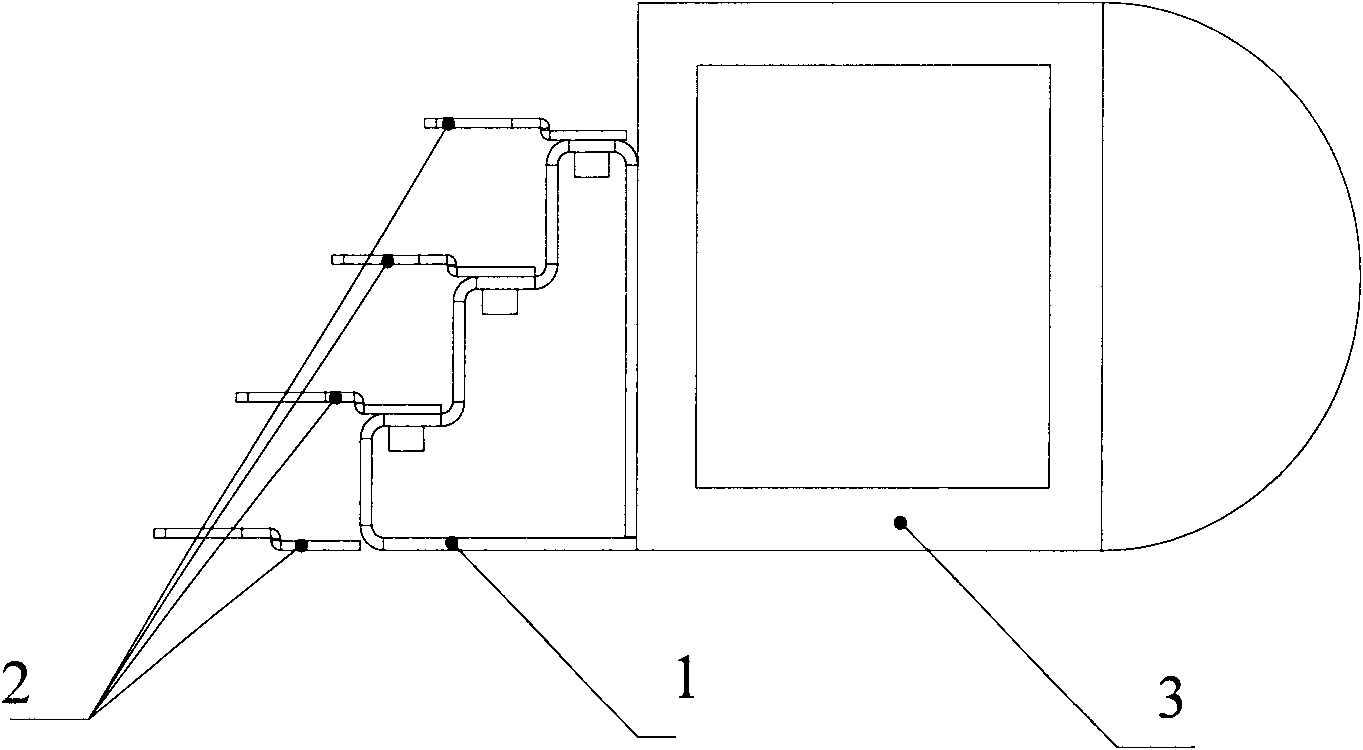

[0013] Such as figure 1 As shown, in this embodiment, multiple pieces (for example, 4 pieces) of stress relief pieces 2 are used to connect to the split bracket 1 , and the split bracket 1 is connected to the drag chain bracket 3 at the same time.

[0014] During construction, according to the number of cables used and the inner diameter of the towline, the number of stress relief sheets 2 to be used is determined. The determination process is as follows: firstly, the inner diameter of the towline is divided by the cable diameter, and the quotient is rounded to obtain The number of cables that can be placed on each layer of the stress relief sheet; then divide the total n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com