Cable joint for connecting a sheathed cable with sheathed part and fixation method of sheathed part

A technology of armored cables and armored parts, which is applied in the field of cable glands for connecting armored cables with armored parts and the fixing of armored parts, which can solve the problems of thread assembly labor, large force, and effort, and achieve Ensure the connection status, improve the efficiency of use, and improve the effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The term "armoring" used in the present invention refers to the use of metal, plastic, and fabrics to weave meshes in order to strengthen marine cables when ships or drill ships are used in applications where there is a lot of sloshing such as the sea surface Or a non-woven reinforcement made in a non-woven manner as tapes, strips or strands, the term "armoring" being used extensively within the same industry.

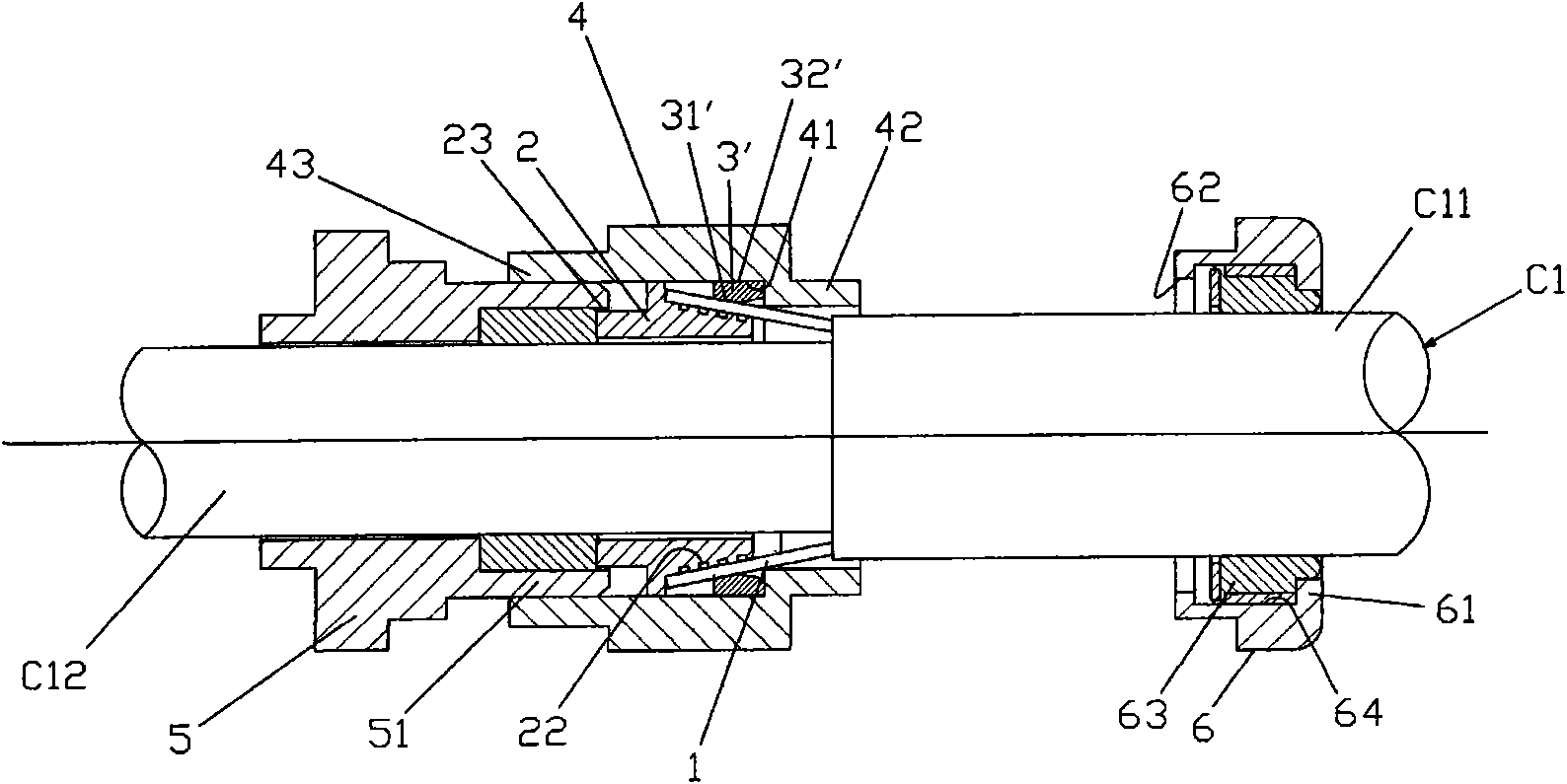

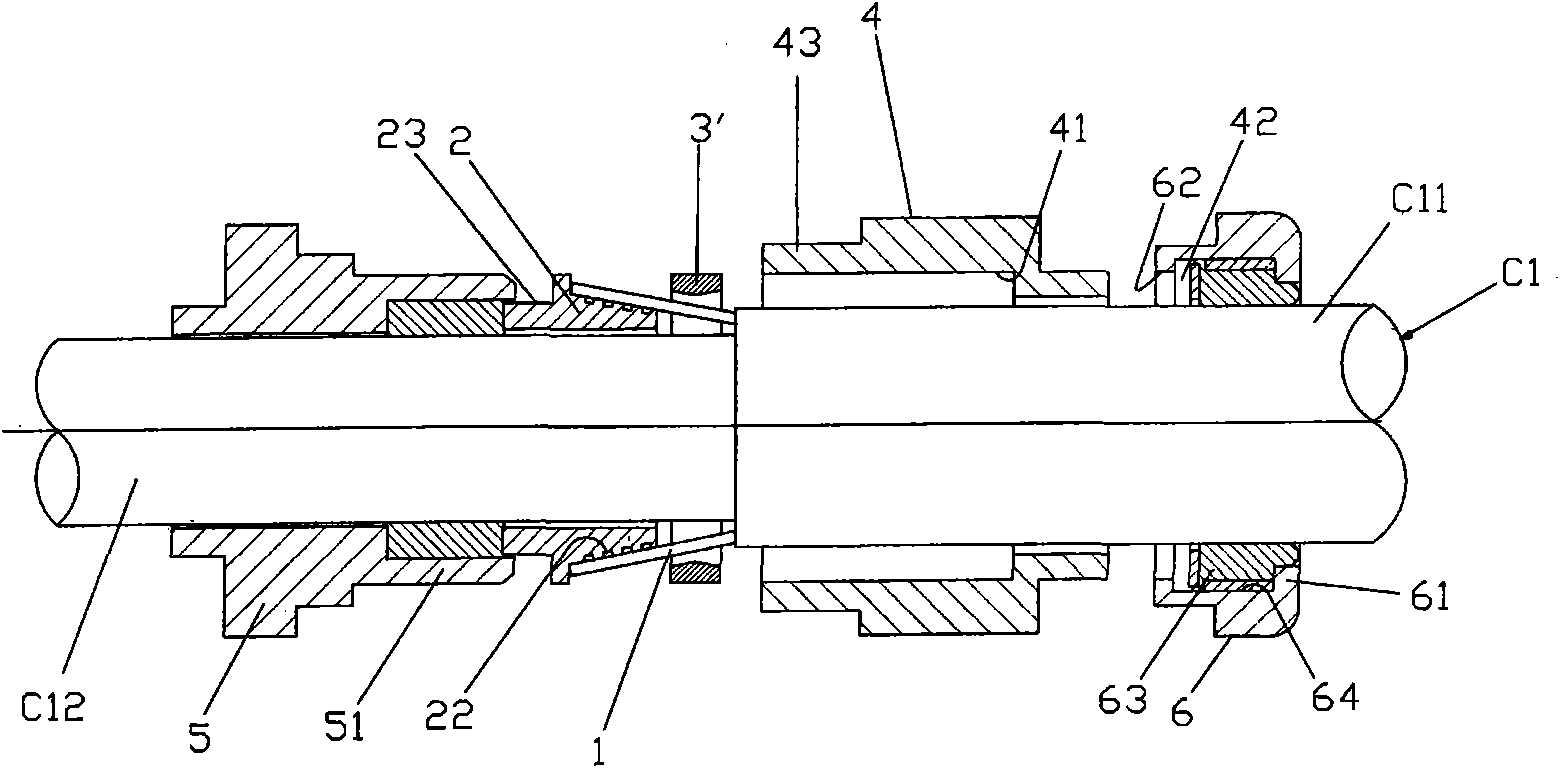

[0024] The armored cable C1 described above includes the armor portion 1 located between the outer sheath C11 and the inner sheath C12. The armor portion 1 of the above-mentioned armored cable C1 can take various forms, such as thicker steel wires such as non-woven steel wires or thin steel wires such as braids, which will not be described in detail in this description.

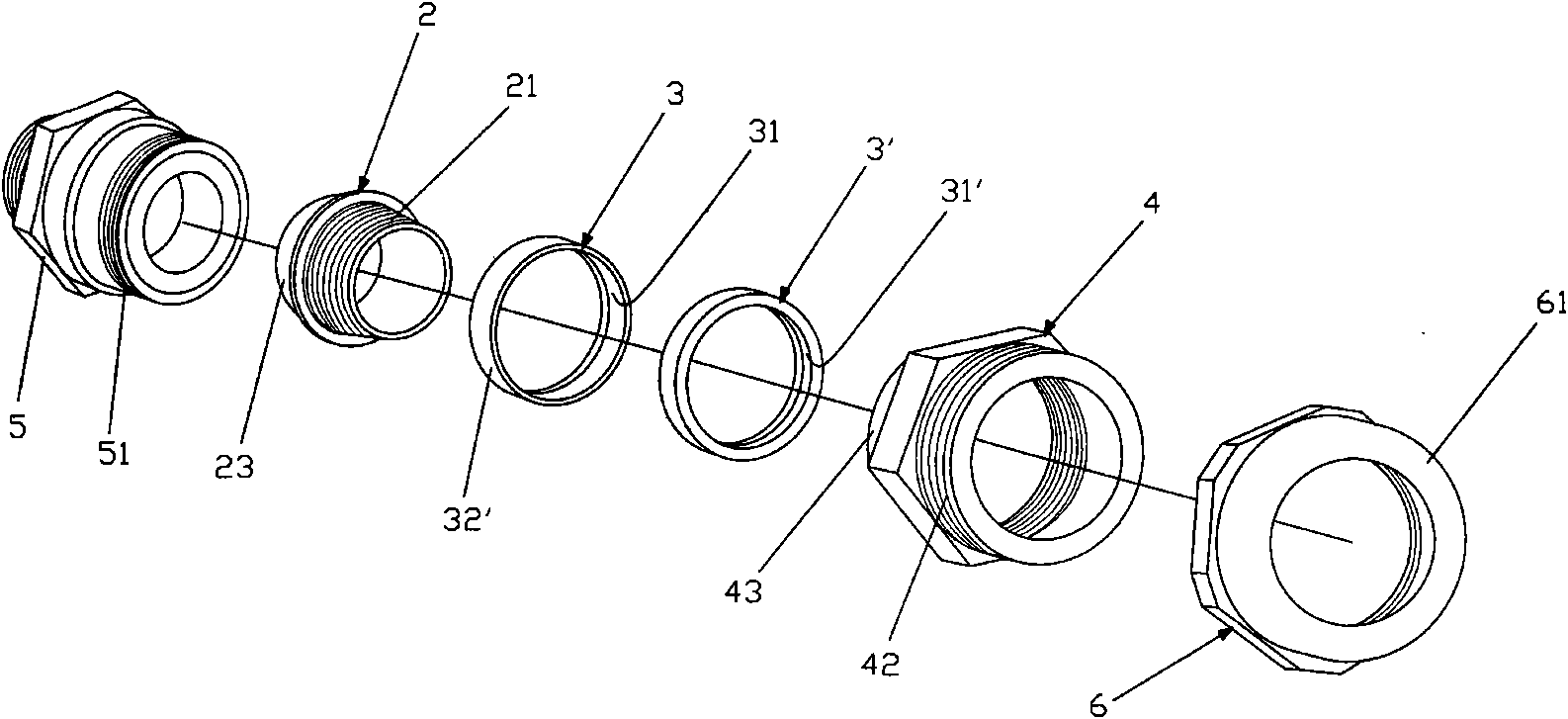

[0025] Such as figure 1 As shown in FIG. 3 , a cable gland A for connecting an armored cable with an armored portion according to an embodiment of the present invention includes: a sleeve 2 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com