Needle bar reciprocating mechanism of sewing machine

A technology of moving mechanism and sewing machine, which is applied in the direction of needle seat for sewing machine, sewing machine element, control device for sewing machine, etc., can solve problems such as replacement of parts, and achieve the effect of realizing sewing quality and avoiding poor sewing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

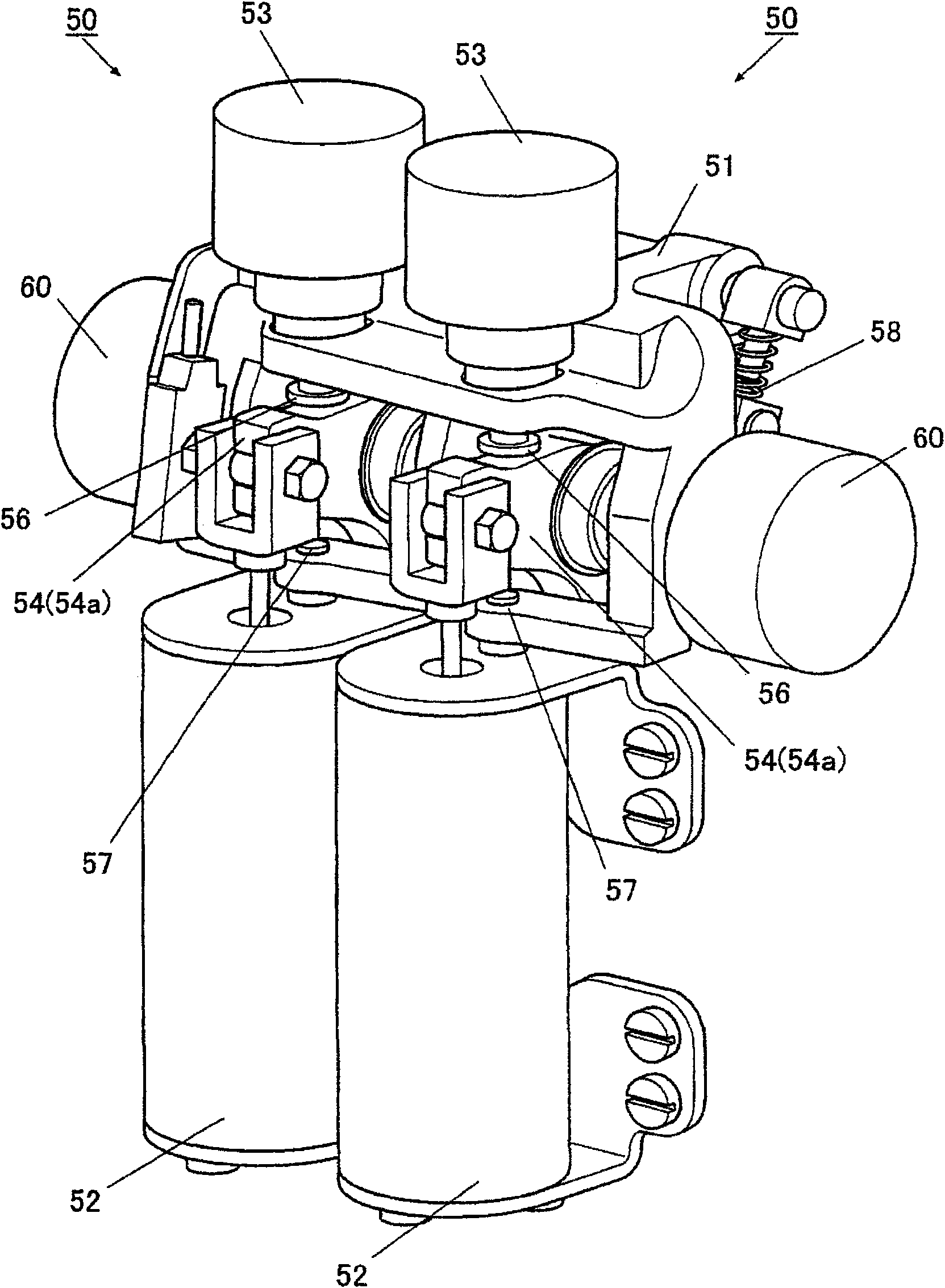

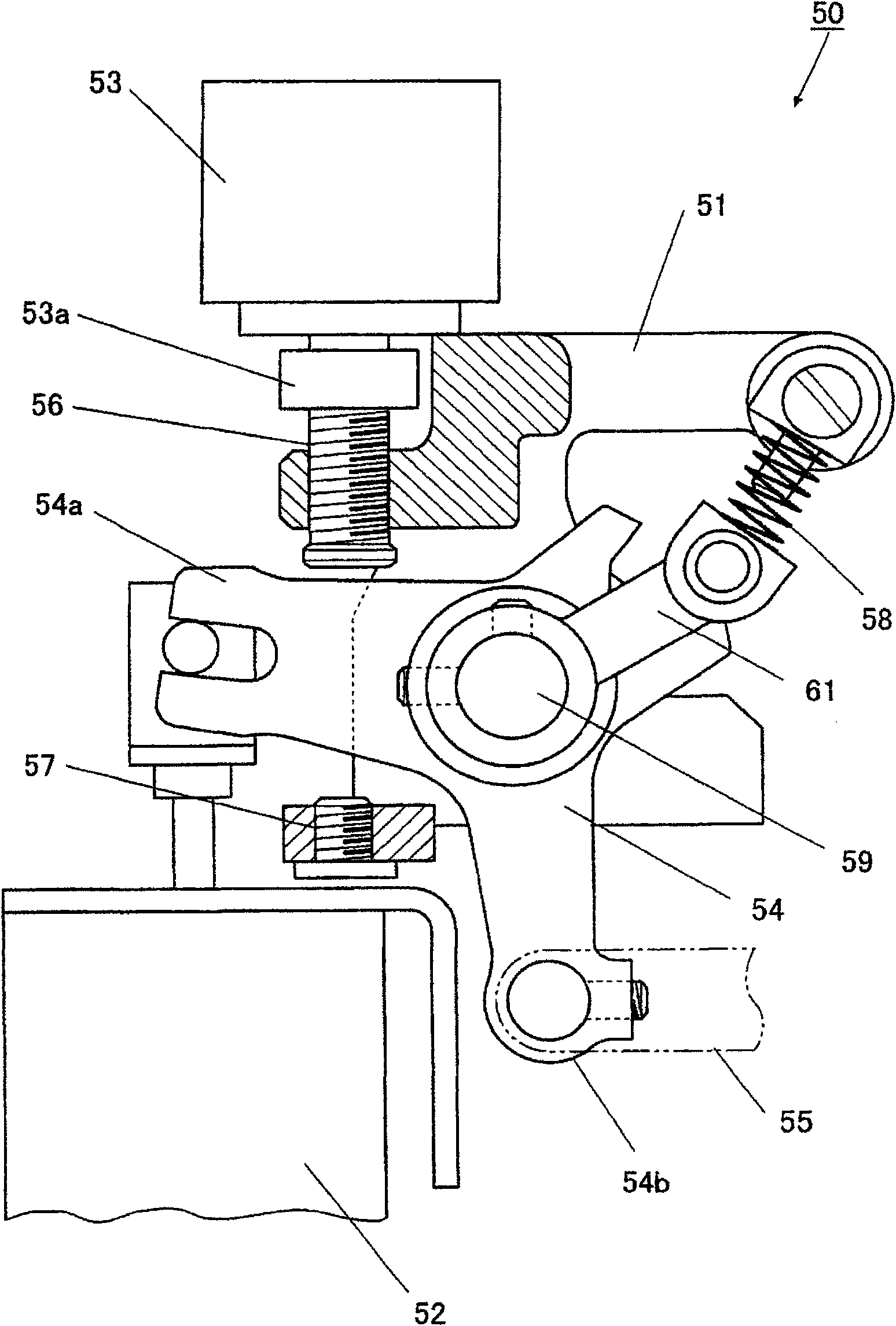

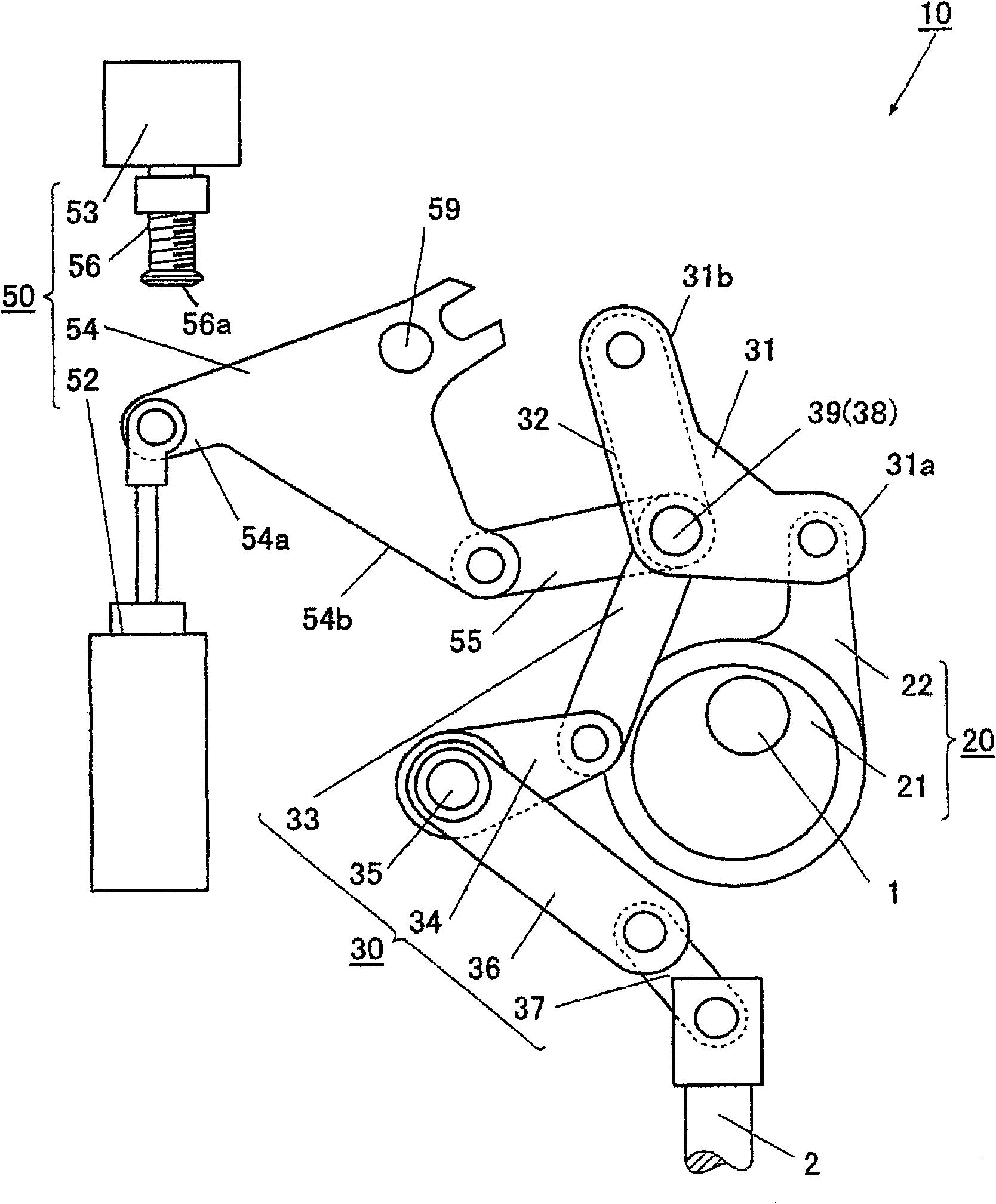

[0032] exist Figure 1 to Figure 4 Among them, the needle bar up and down movement mechanism 10 of the sewing machine has: the main shaft 1, which utilizes the sewing machine motor 3 to perform full-circle rotation; the conversion mechanism 20, which converts the rotation of the main shaft 1, and outputs the reciprocating action; the transmission mechanism 30, which converts the reciprocating action from The conversion mechanism 20 transmits to the needle bar 3 ; and the stroke adjustment mechanism 50 as a movement adjustment mechanism, which adjusts the reciprocating stroke transmitted by the transmission mechanism 30 .

[0033] In addition, since the sewing machine is a double-needle sewing machine, two needle bars 2 are mounted, so the above-mentioned needle bar vertical movement mechanism 10 has two conversion mechanisms 20, a transmission mechanism 30, and a stroke adjustment mechanism 50 respectively, but because they have the same structure, only Describe one of them. ...

no. 2 Embodiment approach

[0068] according to Figure 6 A second embodiment of the present invention will be described.

[0069] In the first embodiment described above, the electromagnetic solenoid 52 and the adjustment motor 53 are provided for each needle bar 130 for adjustment of the needle bar stroke. Instead of this method, in the second embodiment, the needle bar stroke adjustment is performed by one adjustment motor 80 for each needle bar 130 . In the description of the second embodiment, the same components as those of the first embodiment are denoted by the same reference numerals, and detailed description thereof will be omitted.

[0070] In the needle bar vertical movement mechanism 10A of this second embodiment, an adjustment link 81 is provided instead of the aforementioned second bell crank 54 .

[0071] Figure 6 In the illustrated adjustment link 81 , one end side 81 b is connected to the connecting rod 55 , and the other end side is fixedly supported by the support shaft 82 . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com