Shifter mechanism for shift gear box

A technology of shifting mechanism and transmission, applied in mechanical equipment, components with teeth, transmission control and other directions, can solve problems such as difficulty in maintaining accuracy, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

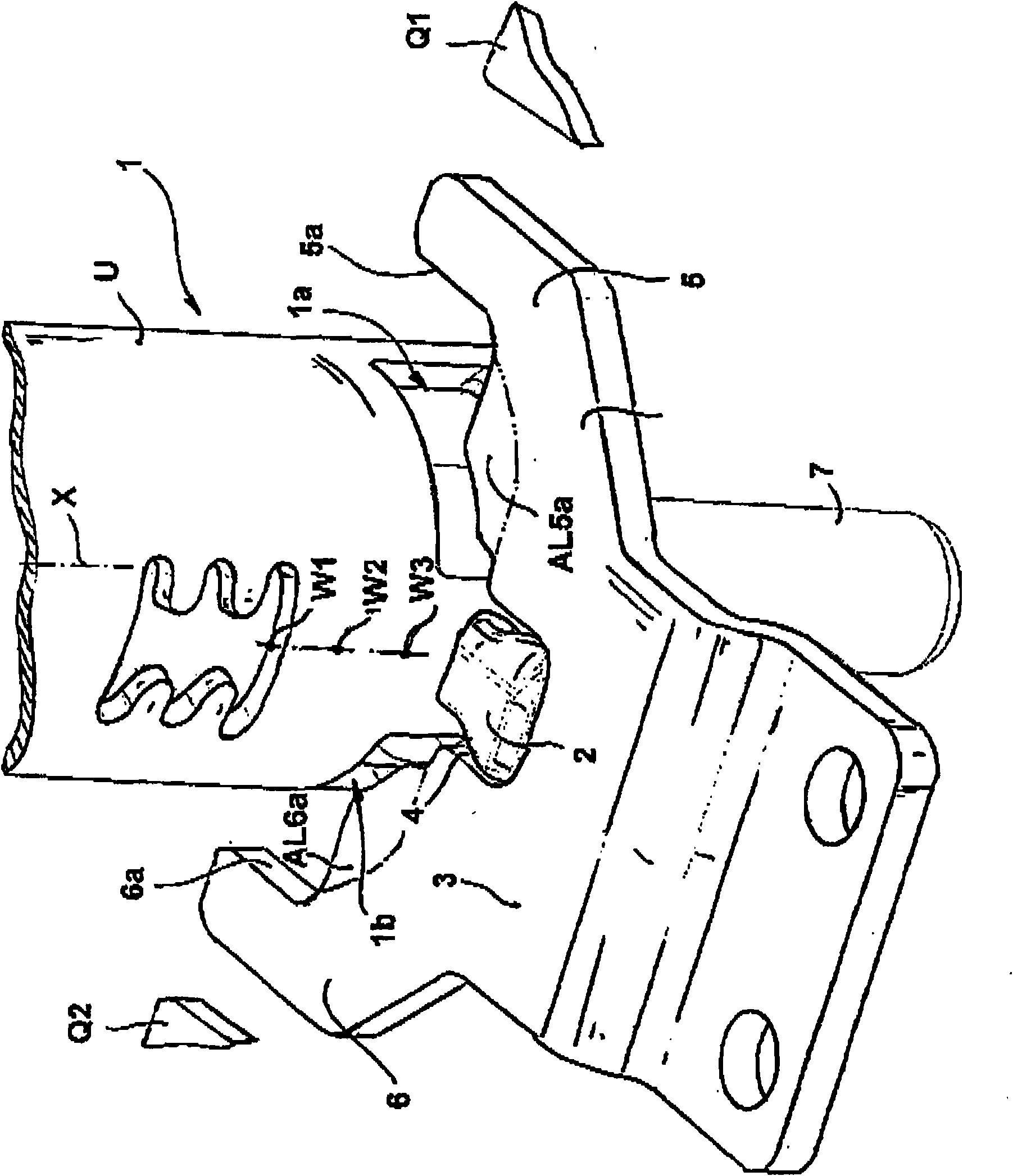

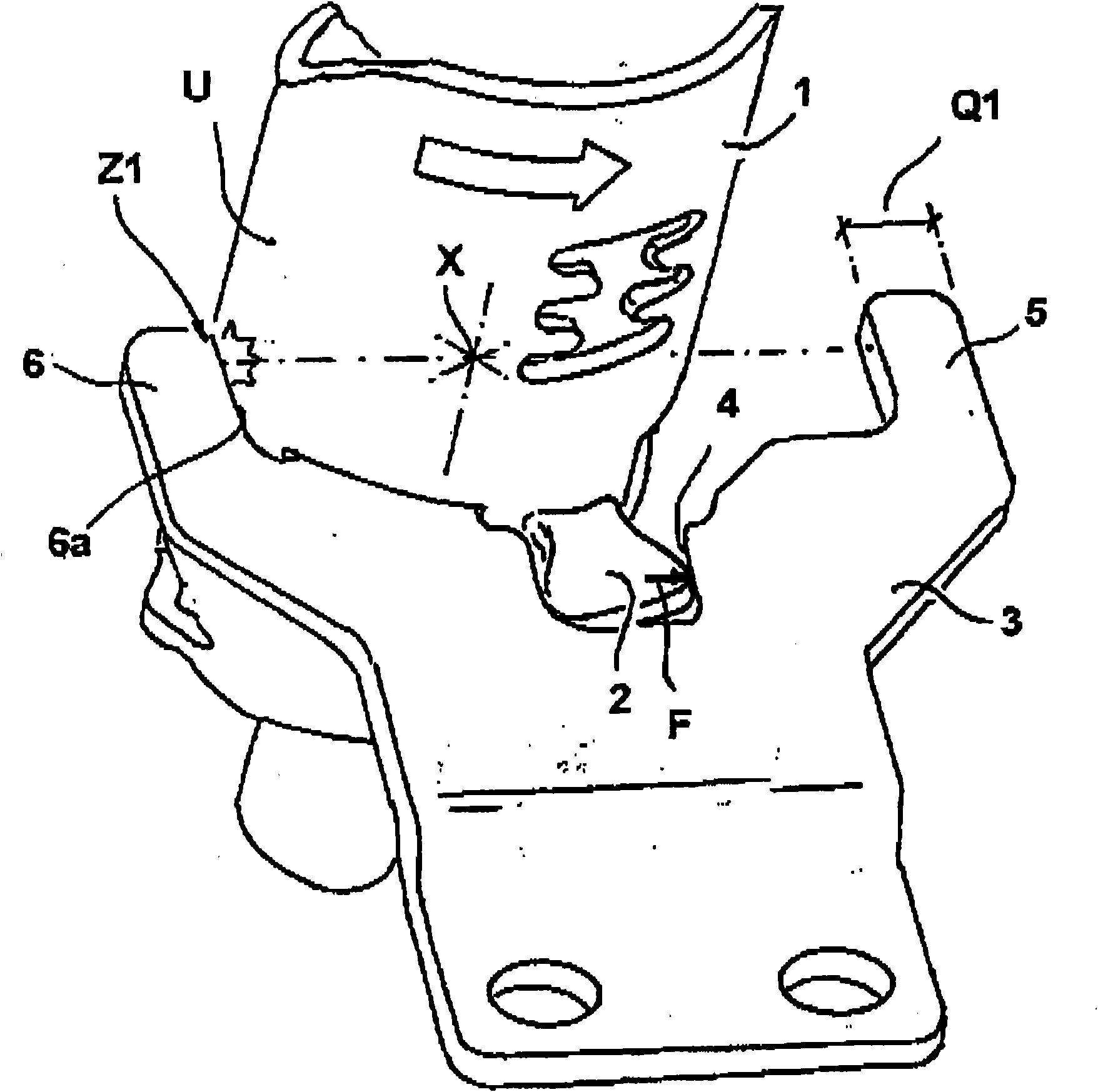

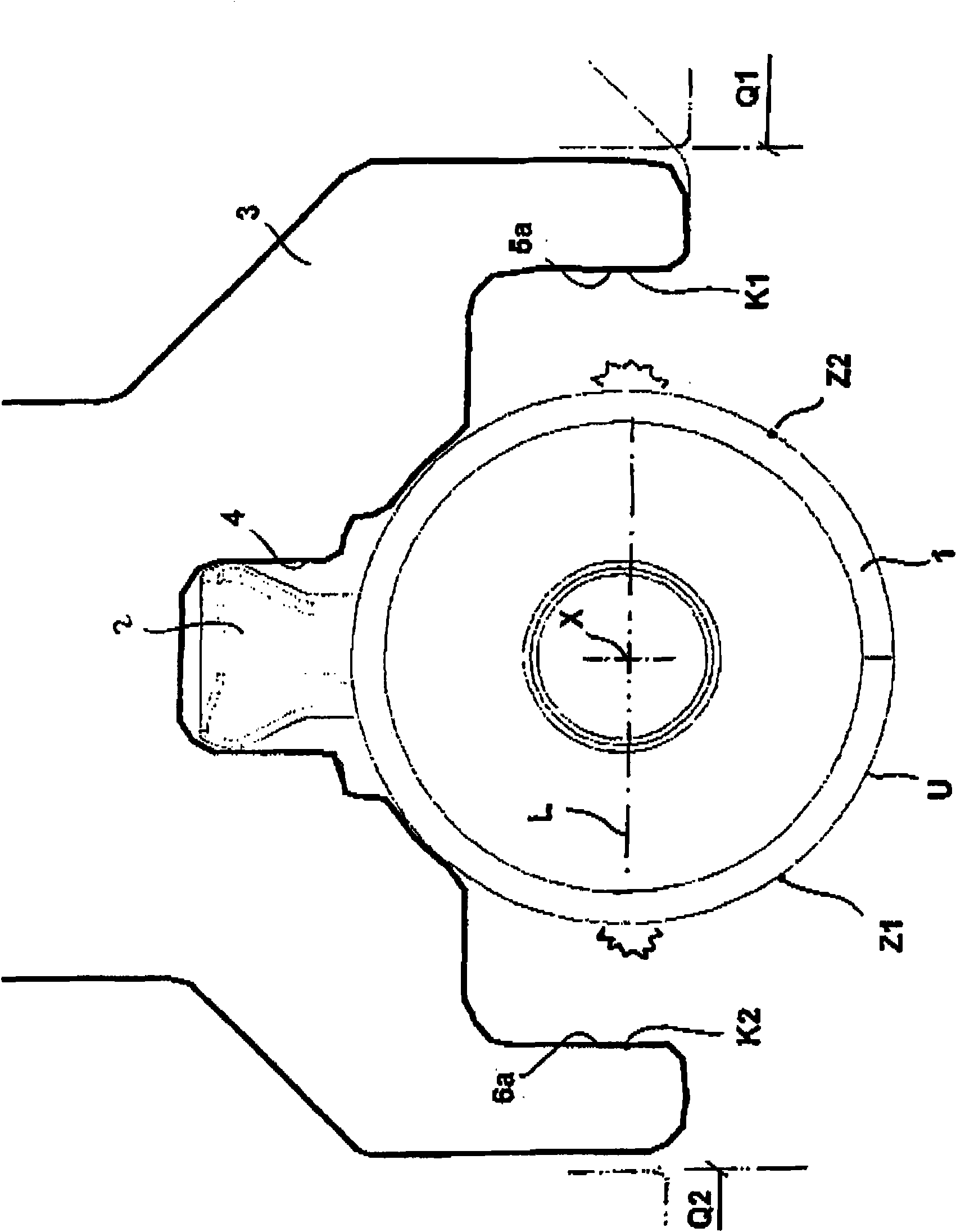

[0022] exist figure 1 The shifting mechanism for a transmission shown in includes a shifting element 1, which is configured as a bush or a hollow shaft and can be moved along its center axis X to different shifting element axial positions W1, W2 , W3. Furthermore, the shifting element 1 can be pivoted in the circumferential direction when the shifting element axial position W1 , W2 , W3 is reached.

[0023] A push rod projection 2 is connected to the shifting element 1 , which push rod projection projects radially beyond the outer circumferential wall U of the shifting element 1 .

[0024] The shifting mechanism also includes at least one, preferably a plurality of shifting arms 3 arranged sequentially along the longitudinal direction of the shifting element 1, the shifting arm has a fork-shaped shift port, and the shift port has a Insert into the engaging groove 4 of the push rod protrusion 2 . The shifting arm 3 is displaceable within the swivel range of the shifting elem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com