Device for taking and placing chaton automatically

An automatic pick-and-place, rhinestone technology, applied in the transmission device, clothing, manipulator and other directions, can solve the problems of low reliability, low drilling speed, small size of rhinestone and empty table and difficult to locate, etc., to avoid damage, Simple and reliable device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in further detail below in conjunction with accompanying drawing:

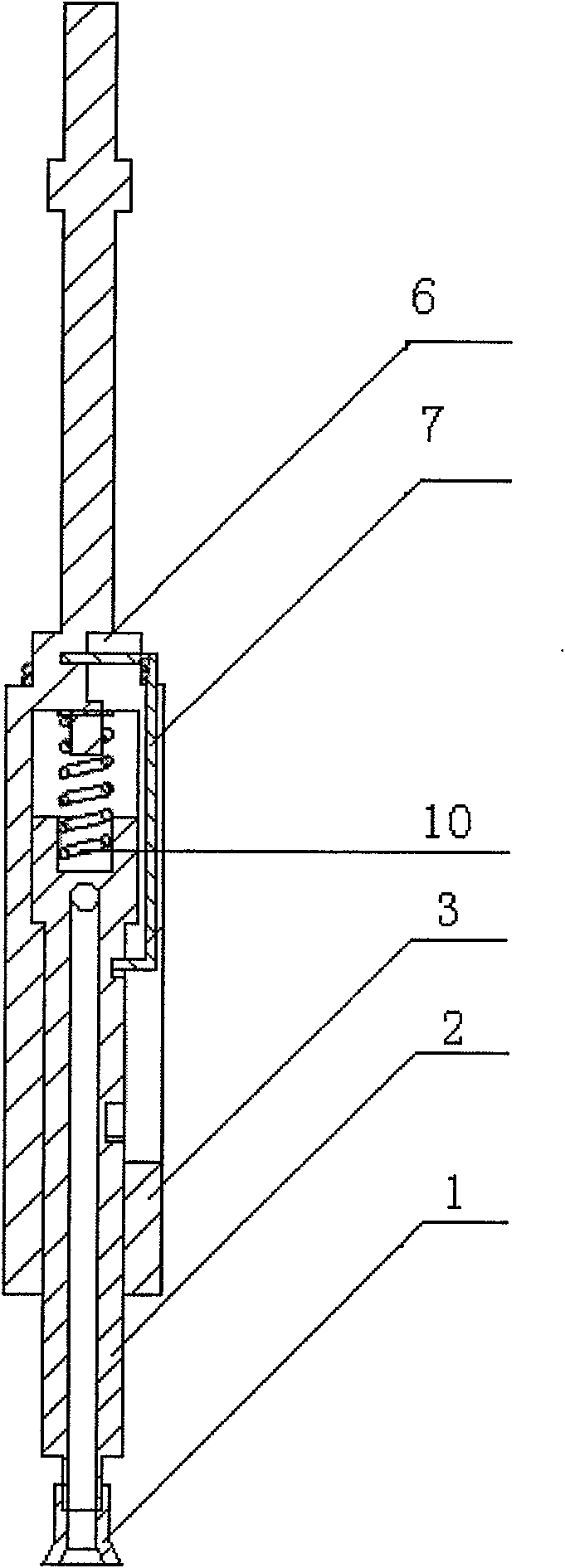

[0015] Referring to the accompanying drawings, the water drill automatic pick-and-place device of the present invention includes two water drill pick-and-place mechanisms, an up and down movement mechanism and a transmission mechanism;

[0016] Transmission mechanism comprises: machine base, vertical concentric inner rotating shaft 22 and outer rotating shaft 23 are installed on the machine base, a sheave driving wheel 25, two sheave driven wheels 26, 27 and two sheave driven wheels are arranged in the machine base cavity. Group transmission gear 24, the top of inner rotating shaft 22 is connected with cam 16, and outer rotating shaft 23 peripheral middle part just connects a transverse plate 21. Have four through holes on the horizontal plate 21, connect with ratchet 28 between inner rotating shaft 22 and outer rotating shaft 23. The sheave driving wheel 25 meshes wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com