Method for processing sweet potato slices

A processing method and technology of sweet potato slices, applied in application, food preparation, food science, etc., can solve problems such as corruption, mildew, environmental pollution, burnt smell, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

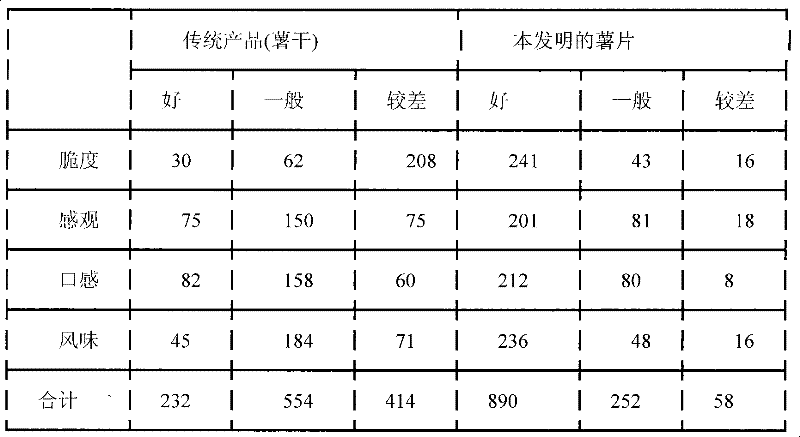

Image

Examples

Embodiment 1

[0015] A processing method of sweet potato chips, comprising the following steps:

[0016] Screening of raw materials: 1. Screening of raw materials: those high-quality sweet potato varieties with high sugar content should be selected, such as left potato, more preferably high-quality sweet potato No. sweetness;

[0017] Slicing: Gently scrape the 1mm skin on the surface of the sweet potato, put it into a slicer, cut into slices with a thickness of 1mm, and store them by classification. Due to the different thicknesses, the finished products have slightly different tastes, which can suit the tastes of different consumers.

[0018] Soaking: prepare the soaking liquid according to the weight of each 50g vitamin C, 50g sodium metabisulfite, 50g protein sugar, 50g crisping agent, 50g leavening agent, 50g citric acid, 50g cyclamate dissolved in 50kg water, and heat the above soaking liquid To 95 ℃, then put the sweet potato slices in, soak for 2 to 5 minutes;

[0019] Dehydratio...

Embodiment 2

[0023] The difference from Example 1 is:

[0024] Slicing: Gently scrape off the 1mm skin on the surface of the sweet potato, put it into a slicer, cut into slices with a thickness of 10mm, and store them by classification.

[0025] Soaking: The heating temperature of the soaking liquid is 100℃, and the sweet potato slices are soaked for 5 minutes;

[0026] Dehydration: The method of natural dehydration can be used. In order to adapt to industrial production, a dehydrator can also be used to keep the water content of sweet potato slices at 25%.

[0027] Frying: Control the oil temperature to 170°C until the surface of the sweet potato slices is golden yellow, and the taste is crisp and crisp.

[0028] Packaging; after quantitative packaging of sweet potatoes, vacuum and kill at 130°C for about 40 minutes.

Embodiment 3

[0030] The difference from Example 1 is:

[0031] Slicing: Gently scrape off the 1mm epidermis on the surface of the sweet potato, put it in a slicer, cut into slices with a thickness of 6mm, and store them by classification.

[0032] Soaking: The heating temperature of the soaking liquid is 98°C, and the sweet potato slices are soaked for 3 minutes;

[0033] Dehydration: The method of natural dehydration can be used. In order to adapt to industrial production, a dehydrator can also be used to keep the water content of sweet potato slices at 20%.

[0034] Frying: control the oil temperature to 150℃, until the surface of the sweet potato slices is golden yellow, and the taste is crisp and crisp.

[0035] Packaging; after quantitative packaging of sweet potatoes, vacuum and kill at 115°C for about 30 minutes.

[0036] In order to adapt to the tastes of different consumers, a mixing step may also be included between the frying step and the packaging step. The mixing step is: mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com