Eleven-layer coextrusion runner system

A laminar flow channel and split flow channel technology, applied in the field of thin film production, can solve the problems of raw material waste, solvent residue, inability to meet the requirements of special multi-layer and multi-color composite film, and achieve the effect of saving energy and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

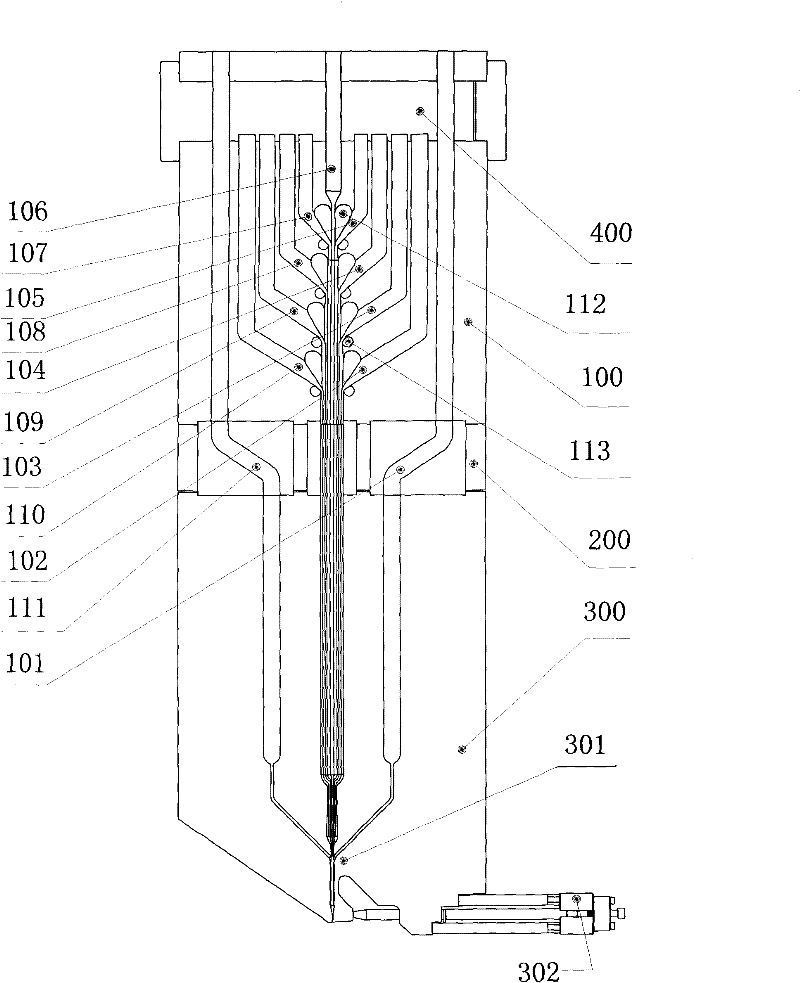

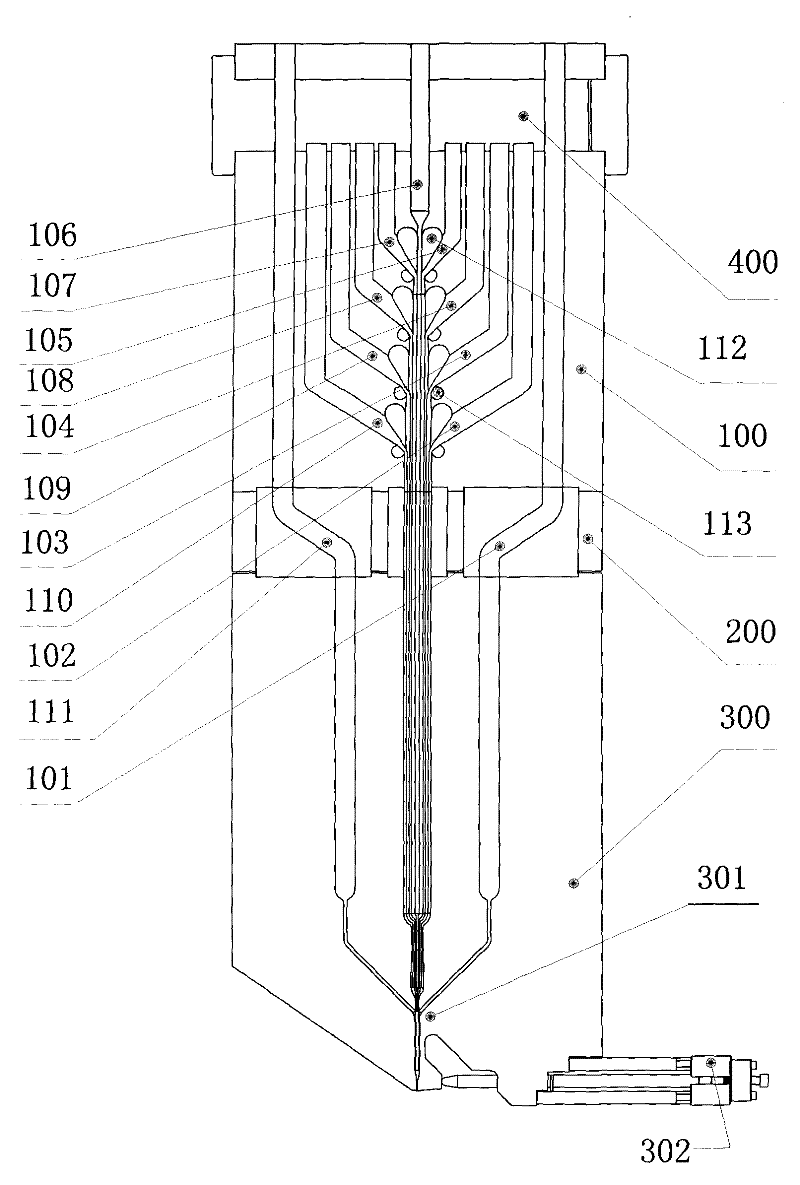

[0009] See attached figure 1 As shown, this embodiment is mainly composed of a distributor 100, an adapter 200, and a three-channel die head 300. The channel switching valve 400 is fixed in the main body hole at the top of the distributor 100 with screws. The channel switching valve 400 can be processed into a suitable process. If the required flow path sequence needs to be converted to other flow path sequence, only one flow path switching valve needs to be replaced. A total of eleven layers of flow channels are set in the distributor 100, the sixth layer of flow channels 106 is located in the center, and other flow channels are arranged in groups of two around the sixth layer of flow channels 106 in a clothes hanger shape from inside to outside. Among them, the fifth layer The flow channel 105 and the seventh layer of flow channel 107 are the first group, the fourth layer of flow channel 104 and the eighth layer of flow channel 108 are the second group, the third layer of fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com