Circular knitting machine with a rotatable installed dial

A circular knitting machine, needle disc technology, applied in the direction of circular knitting, knitting, weft knitting, etc. for weft knitting with individual action needles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

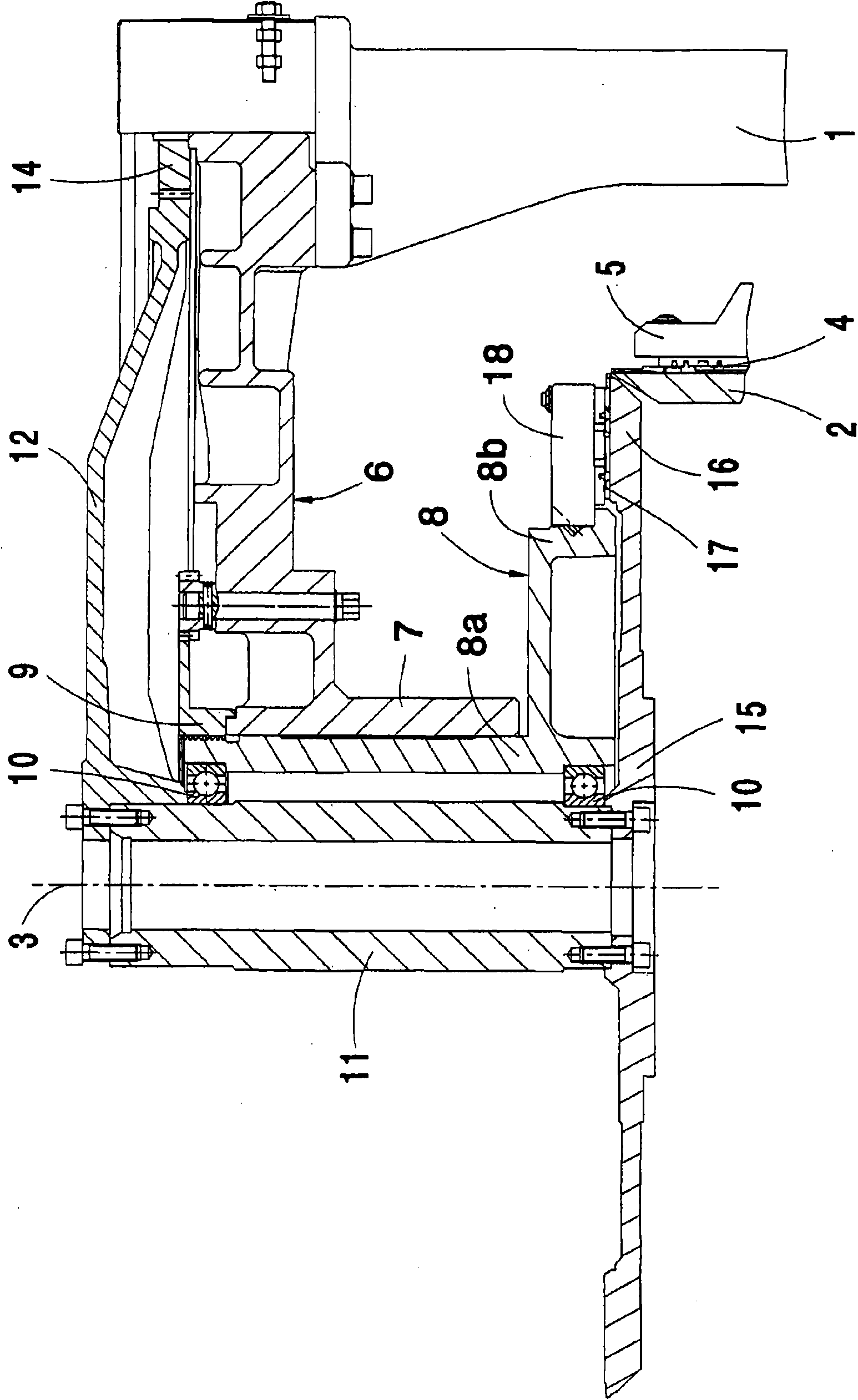

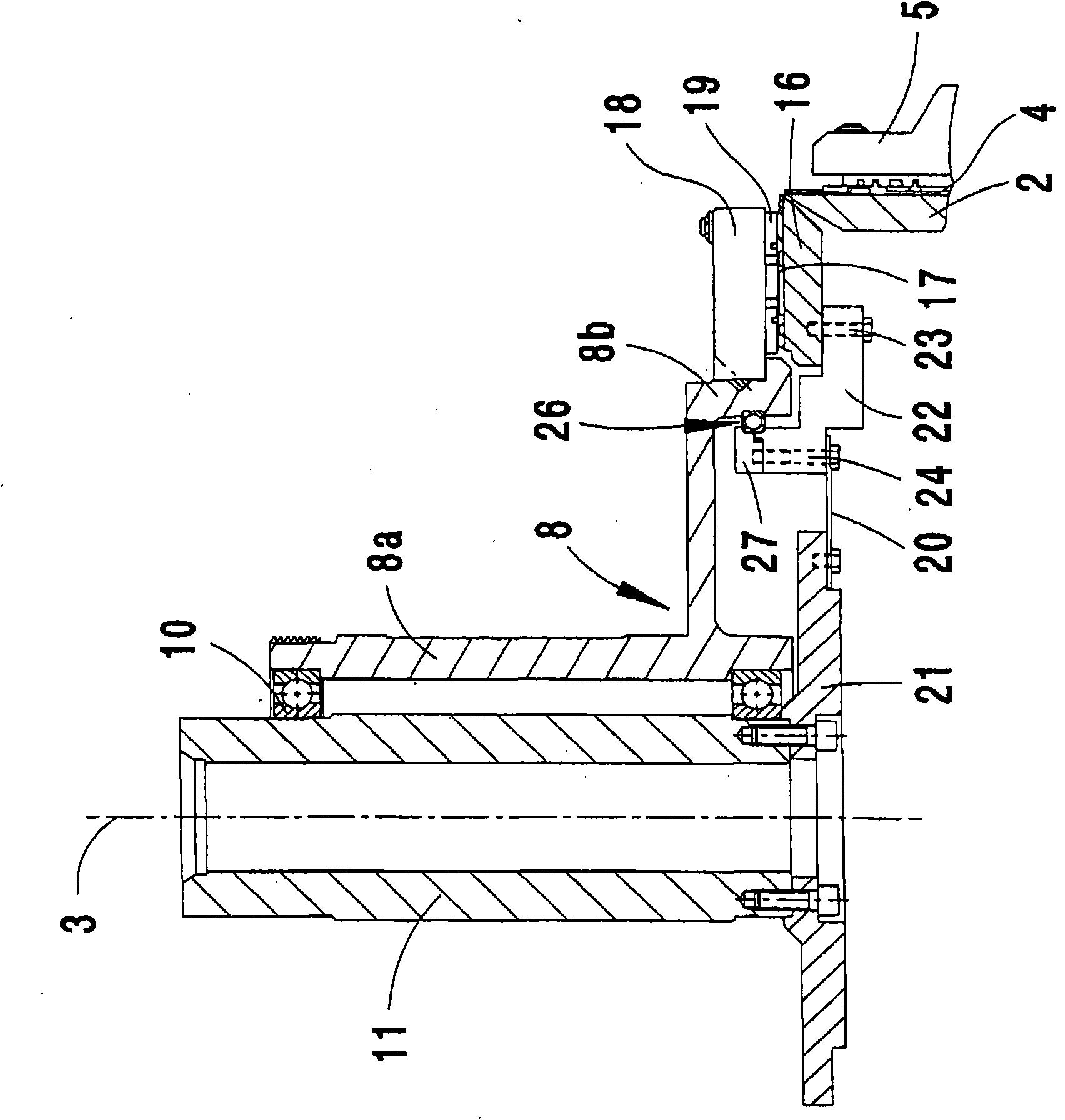

[0013] figure 1 shows a conventional circular knitting machine, with frame 1, in figure 1 Only one of its vertical columns is shown in . A fixed lower support ring (not shown) is fixed in the frame 1, in which is arranged a syringe 2 which is rotatable about a rotation axis 3 and which can be driven in rotation using a conventional drive motor. The usual knitting needles 4 are arranged axially displaceable in the cylinder 2, the knitting needles 4 being moved in the usual manner by means of cylinder cams 5 .

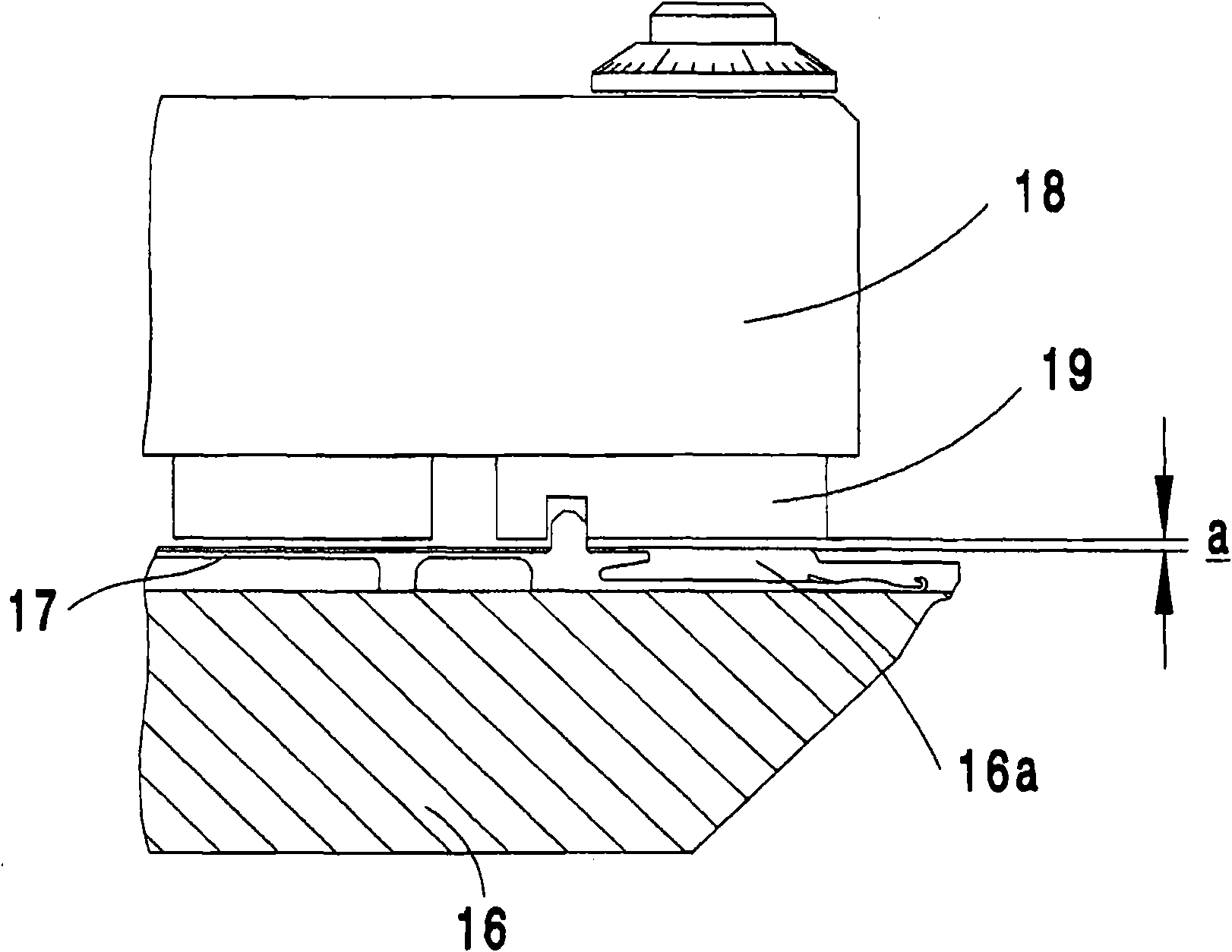

[0014] In the upper part of the circular knitting machine, the columns of the frame 1 are connected to the upper support ring 6 with bearing bushes 7 coaxial with the axis of rotation 3 and in which a fixed dial cam support 8 is arranged The hollow cylindrical part 8a. This hollow cylindrical part 8 a has an externally threaded part at the upper end which is screwed into an internally threaded part of an adjustment wheel 9 arranged axially immovable but rotatable in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com