Improved star-shaped feeding machine

A star-shaped feeder, rack technology, applied in the direction of fuel supply, combustion method, block/powder supply/distribution, etc., can solve problems such as fire, boiler tempering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

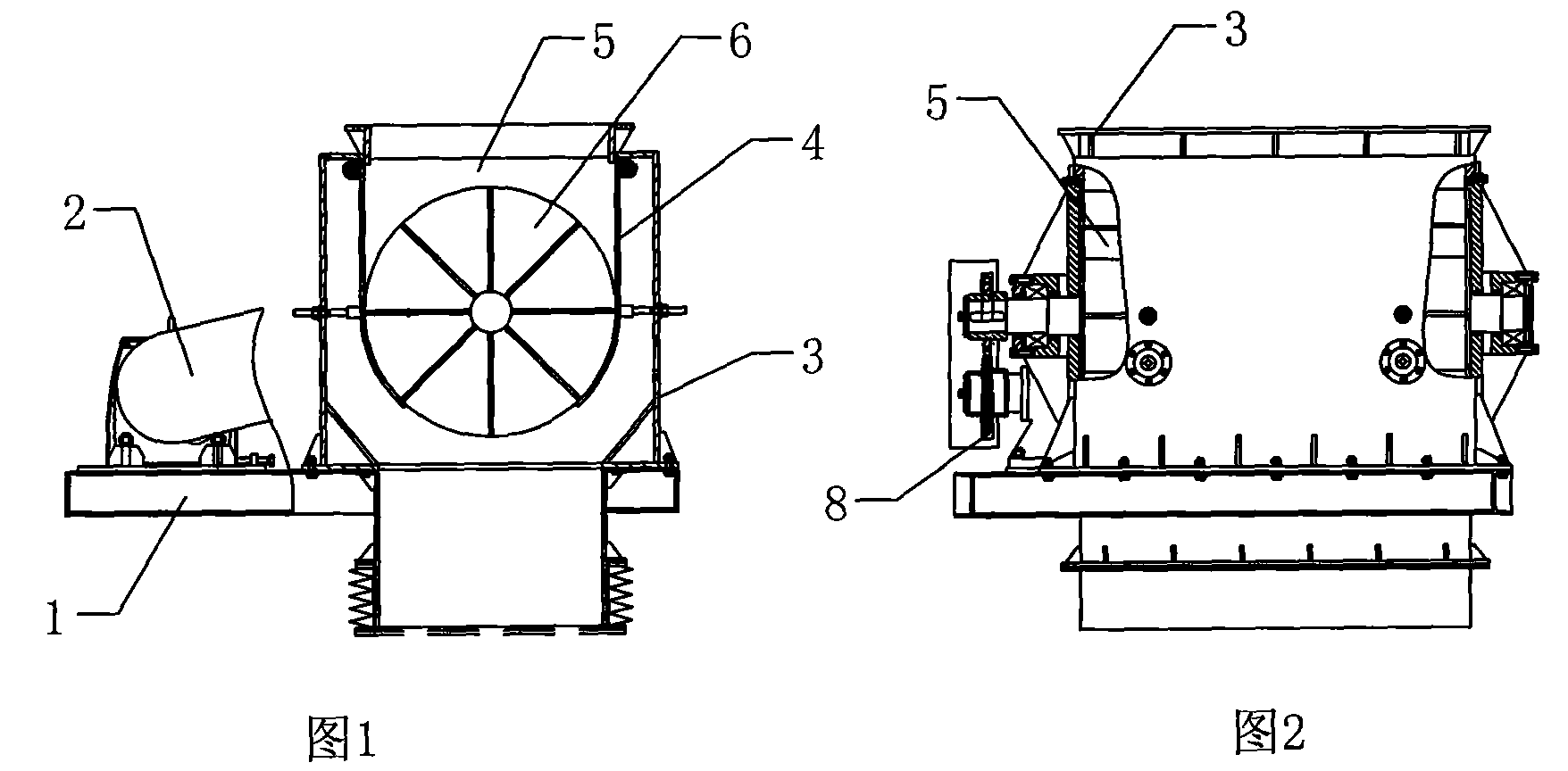

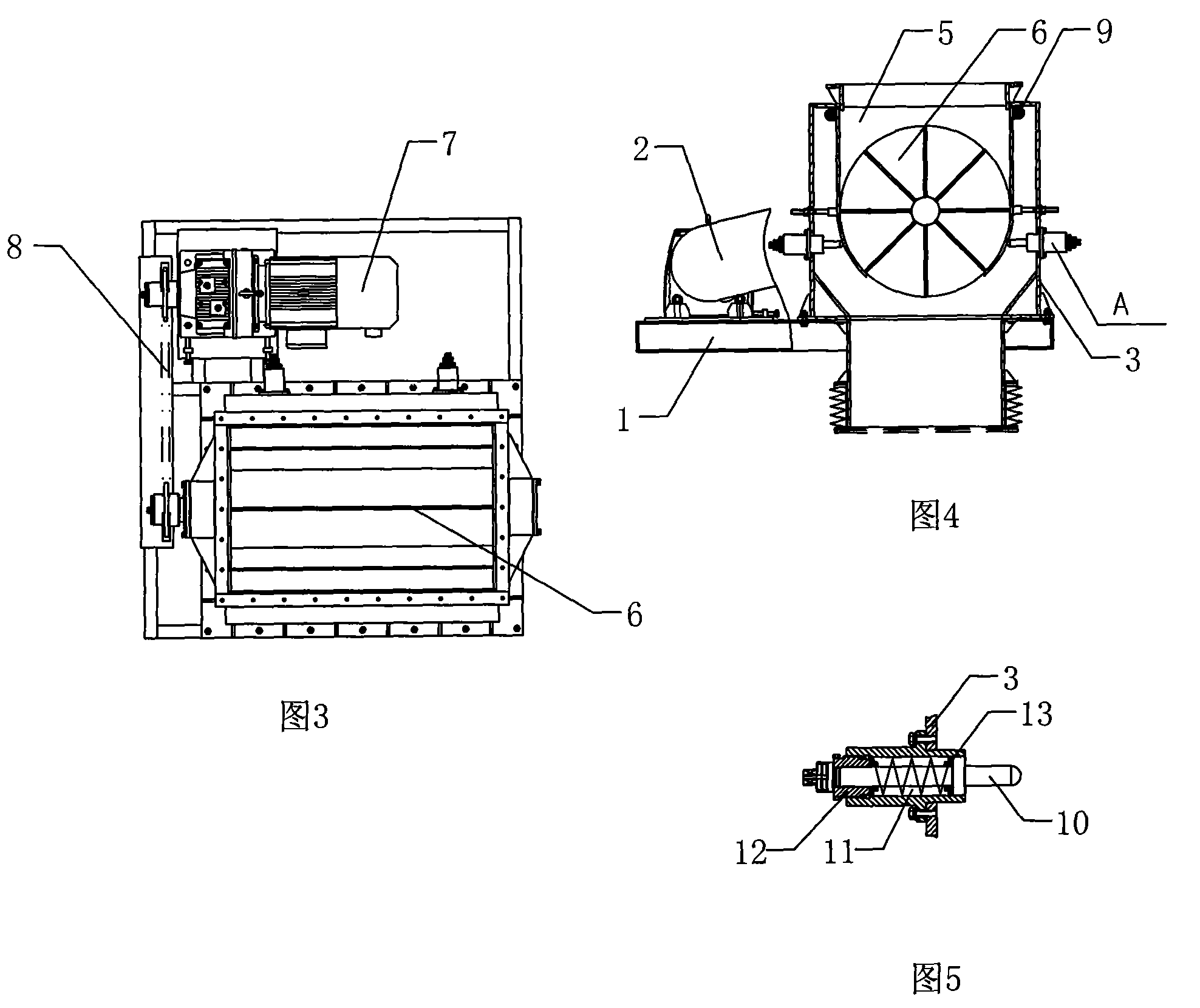

[0012] See figure 2 , image 3 , Figure 4 , the present invention comprises frame 1, and motor 7 is installed on frame 1, and feed funnel 3 is installed on frame 1, and rotor 5 is arranged in funnel 3, and rotor 5 is connected with motor 7 by chain 8, and the rotating shaft of rotor 5 and funnel 3's centerline is vertical. The part where the rotor 5 and the funnel 3 are combined is provided with a U-row bucket 4, the bottom of the U-row bucket 4 is airtight, the outer edge of the rotor blade 6 of the rotor 5 is in contact with the U-row bucket 4, and the U-row bucket 4 is installed by supporting the rotating shaft 9 In the funnel 3 , an anti-jamming device A is provided on the outer side of the arc where the rotor 5 and the U-shaped bucket 4 are combined. The anti-jamming device A includes a jacking shaft 10, the jacking shaft 10 is installed on the shaft sleeve 13, the shaft shoulder of the jacking shaft 10 is in clearance fit with one end of the shaft sleeve 13, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com