Packing shaft seal structure of improved type vertical pump

A vertical pump, an improved technology, applied in the direction of non-variable-capacity pumps, pumps, pump components, etc., can solve the problems of water pump damage, poor water flow, inconvenient structural disassembly and assembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

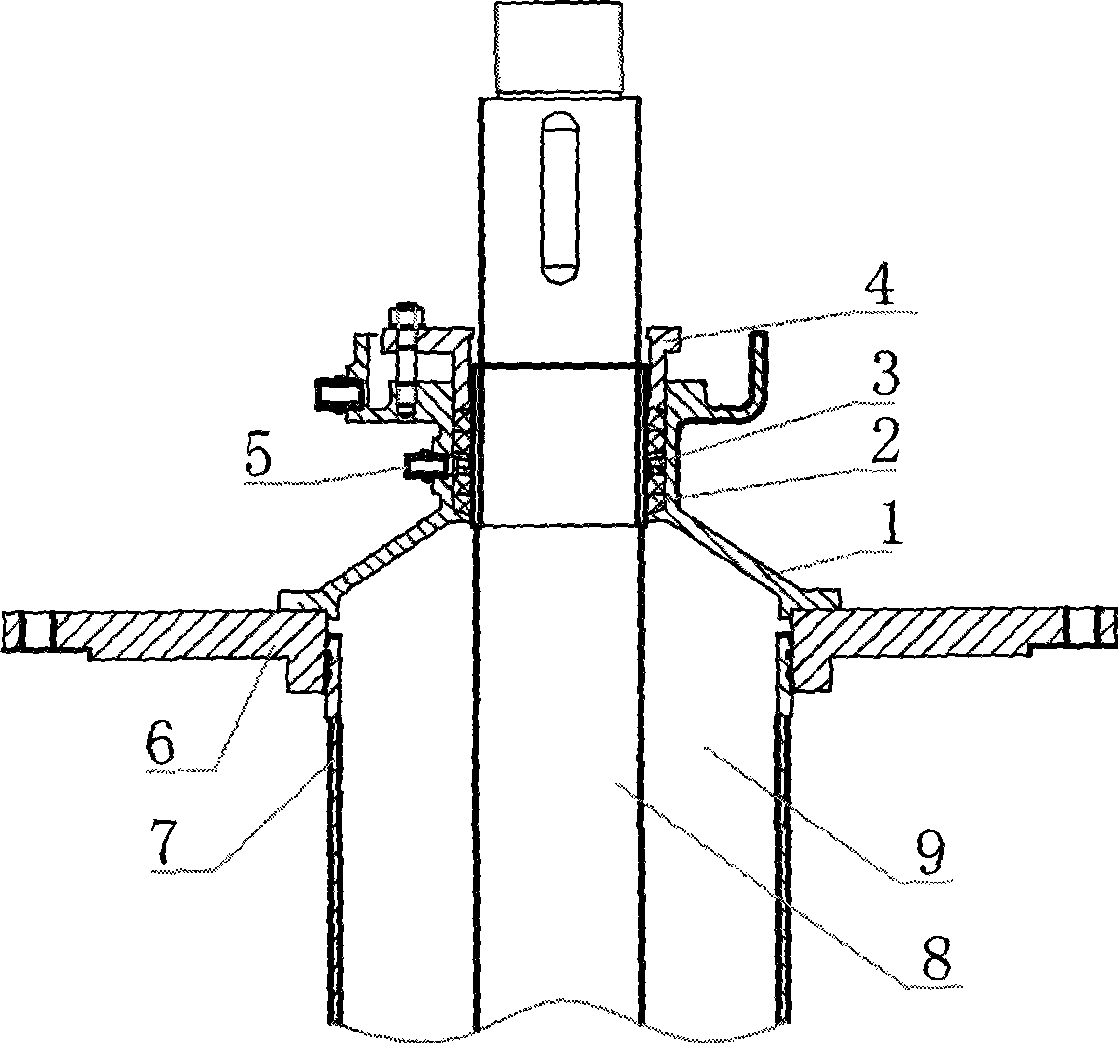

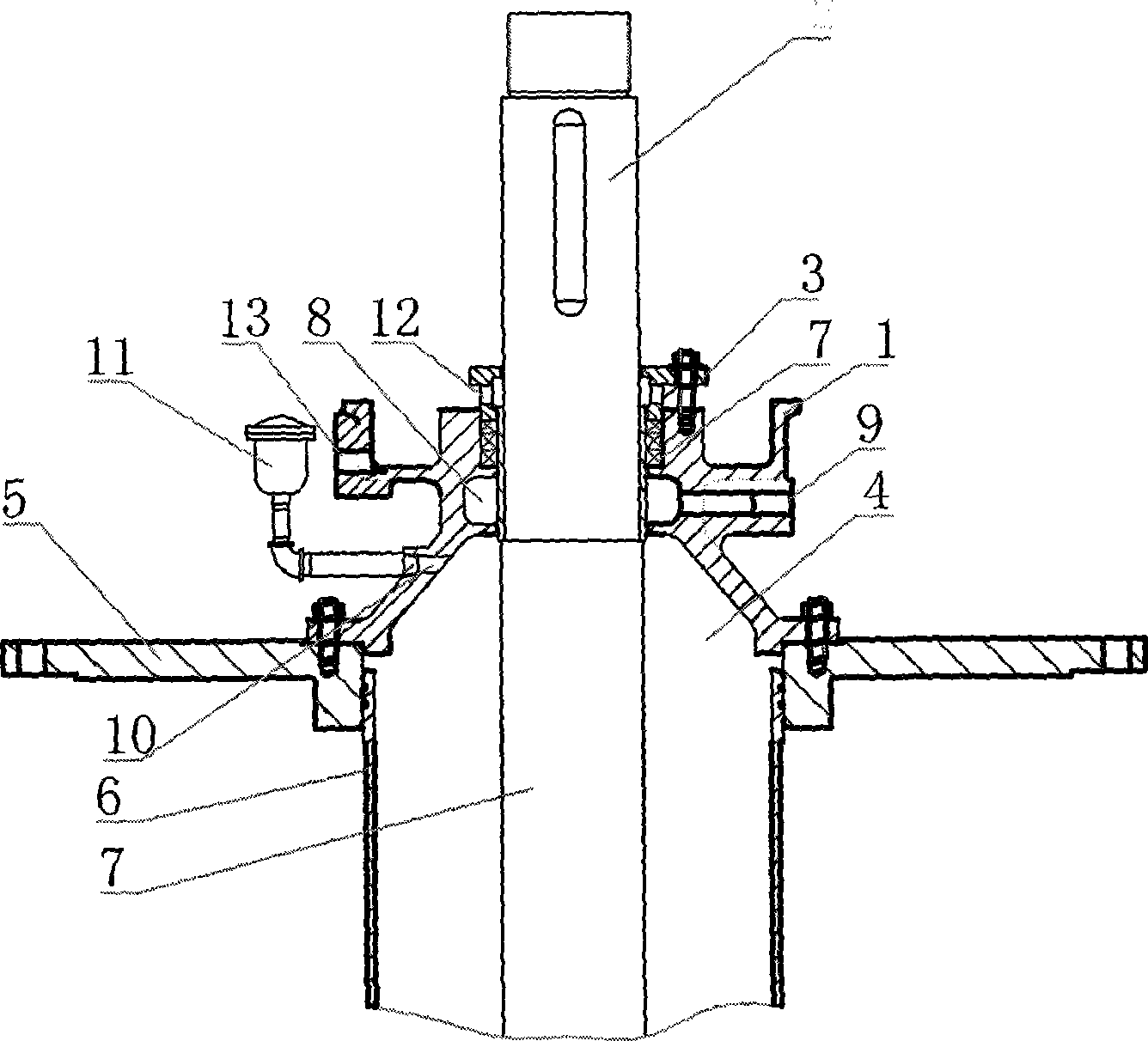

[0009] See figure 2 , the present invention includes a pump shaft 2, a packing seat 1, a packing gland 3, and a pump cover 5, the packing seat 1 is set on the pump shaft 2, the packing gland 3 is installed on the upper part of the packing seat 1, and the lower part of the packing seat 1 is fastened to the pump cover 5. The pump cover 5 is connected to the bearing protection tube 6. The packing seat 1, the pump shaft 2 and the bearing protection tube 6 form a cavity 4. The packing seat 1 is set on the pump shaft 2 to form two upper and lower annular cavities 7 and 8. The upper annular chamber 7 is filled with filler, the lower annular chamber 8 is connected to the water inlet 9, the water inlet 9 is located on the side of the packing seat 1, and the lower annular chamber 8 is connected to the cavity 4 through the gap between the packing seat 1 and the pump shaft 2, The air outlet hole 10 at the lower part of the stuffing seat 4 communicates with the cavity 4 . The air outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com