Biological treatment method and device for organic wastewater

A biological treatment, organic technology, applied in sustainable biological treatment, biological water/sewage treatment, water treatment parameter control, etc., can solve the problems of unstable sludge reduction effect and no stable maintenance method for small animals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

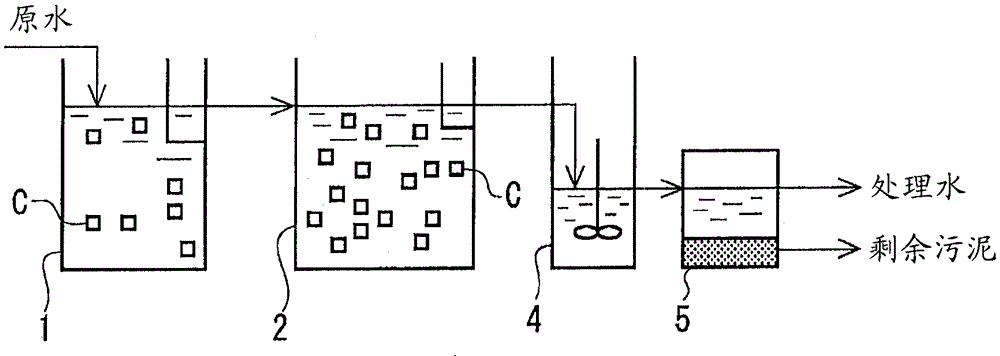

[0052] according to image 3 The flow shown is to treat the raw water (mix fish extract, wild vegetable extract, and liquid sugar in a weight ratio of 2:2:1, and adjust the BOD to 650 mg / L). The capacity of the first biological treatment tank 1 is 2.5L, and the capacity of the second biological treatment tank 2 is 4.4L. According to the raw water supply rate of 21L / day, only the DO of the first biological treatment tank 1 is 0.01mg / L, and the second The DO of the biological treatment tank 2 is 2-3 mg / L for aeration and operation.

[0053] In addition, a sponge having an average particle diameter of 3 mm square was filled as a carrier in the first biological treatment tank 1 at a filling rate of 5%, and in the second biological treatment tank at a filling rate of 40%.

[0054] The BOD volume load relative to the first biological treatment tank is 5.5kg-BOD / m 3 / d, HRT is 3.5h, overall BOD volume load is 2.0kg-BOD / m 3 / d, HRT9.6h under the conditions of operation. The result...

reference example 1

[0056] exist image 3 50% of the excess sludge deposited in the settling tank 5 was returned to the second biological treatment tank 2, and the operation was carried out under the same conditions as in Example 1 except for prolonging the sludge residence time.

[0057] As a result, the proliferating sessile microfauna settles not on the carrier but on the returned sludge flocs, and when the flocs disintegrate with load fluctuations or steady changes, they flow out of the system. Other running results are shown in Table 1. As shown in Table 1, the average sludge conversion rate was 0.42kg-MLSS / kg-BOD. From the above results, compared with this reference example 1, the sludge conversion rate of Example 1 which does not return sludge to a 2nd biological treatment tank becomes low.

[0058] Table 1

[0059]

Embodiment 2

[0061] according to Figure 4 The shown flow process treats the same raw water as in Example 1. In this embodiment 2, a third biological treatment tank 6 with a capacity of 4 L is connected to the sedimentation tank 5 in the embodiment 1. The DO of the third biological treatment tank 6 is 2 to 3 mg / L. In addition, as in Example 1, the same carrier was filled in the first biological treatment tank 1 at a filling rate of 5% and in the second biological treatment tank 2 at a filling rate of 40%. Same as Example 1, the BOD volume load relative to the first biological treatment tank is 5.5kg-BOD / m 3 / d, HRT is 3.5h, overall BOD volume load is 2.0kg-BOD / m 3 / d, HRT9.6h under the conditions of operation.

[0062] The sludge in the tank was taken out from the third biological treatment tank 6 as excess sludge 0.4 L / d, and the excess sludge 0.4 L / d was added to the third biological treatment tank 6 from the sedimentation tank 5 . Furthermore, lecithin was added as a nutrient once ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com