Cable trolley protector for construction elevator

A technology for construction elevators and protectors, which is applied to elevators, elevators in buildings, transportation and packaging, etc. It can solve problems such as messy wires, limited elevator lifting height, and damage to cable trolleys. The method is simple, reliable, and easy to install and use. , The effect of protecting the cable trolley

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

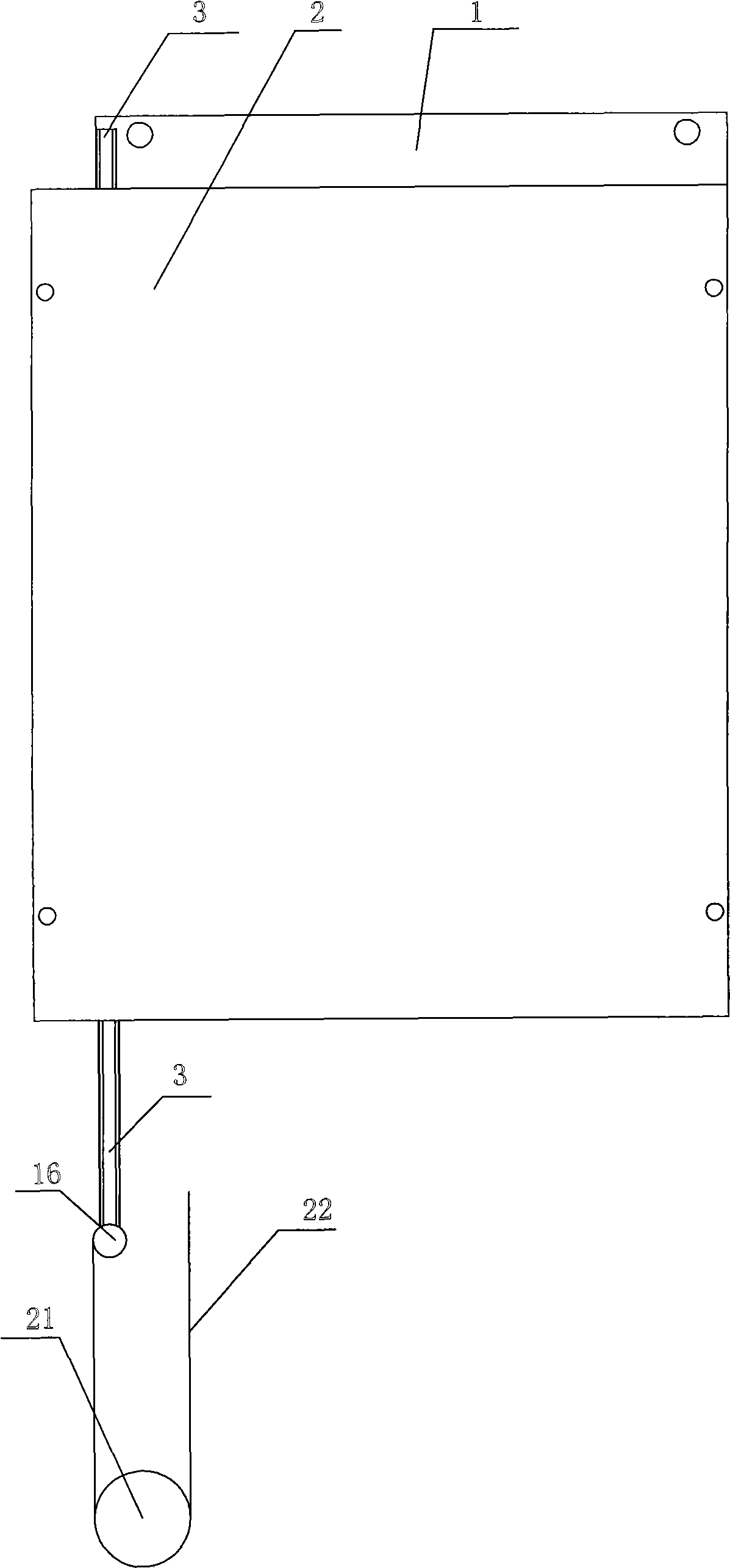

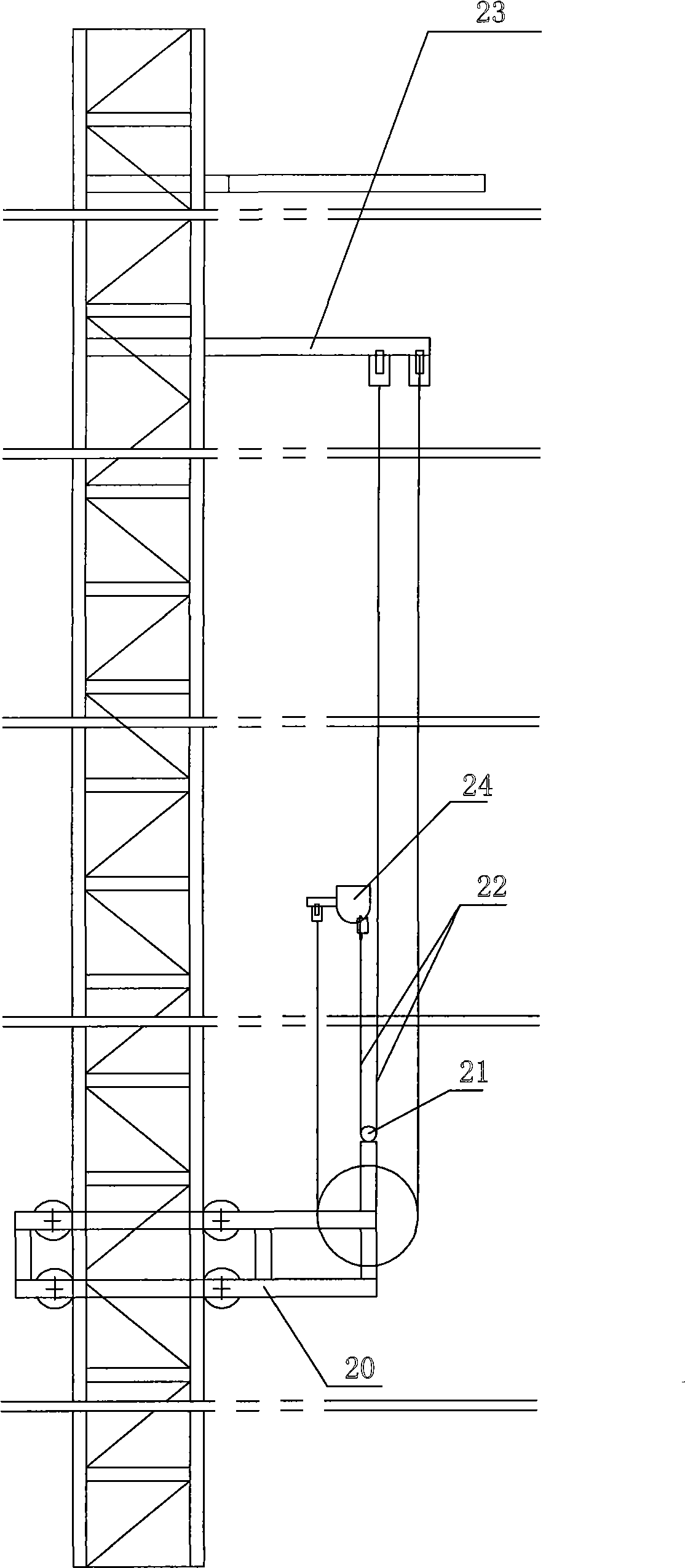

[0020] like figure 1 , figure 2 As shown, the construction hoist cable trolley protector of the present invention includes a housing, a limit switch 11 and a pull rod 3, the pull rod 3 is provided with threads, and the housing includes a bottom plate 1 and a cover plate 2 matched with the bottom plate 1, and the bottom plate 1 Also fixedly be provided with upper bearing 5 of pull rod and lower bearing 6 of pull rod, pull rod 3 wears on the upper and lower bearings 5,6 of the pull rod and is slidingly matched with the upper and lower bearings 5,6 of the pull rod. The middle part of the pull rod 3 is also provided with upper and lower adjustment nuts 9, 10, and the bottom of the pull rod 3 is also sleeved with a spring 8. The bottom end of the pull rod 3 is also provided with a pull ring 16, and the middle part of the pull rod 3 is also provided with upper and lower dials 12, 13 which are integrally arranged. Shape, the top of the upper dial 12 is press-fitted with the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com