Peanut paste with reasonable fatty acid proportion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

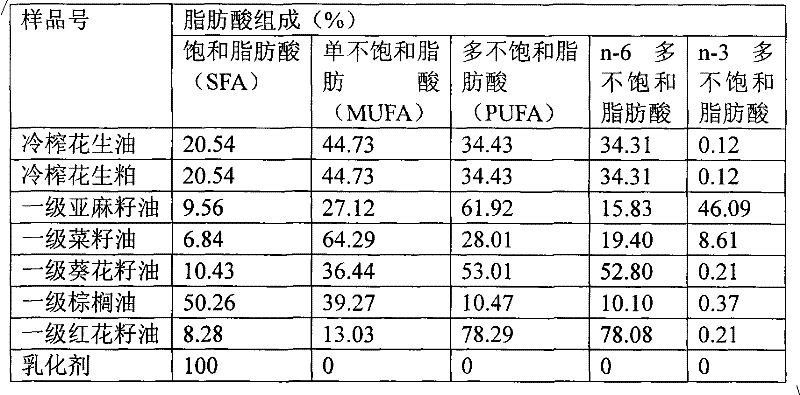

Embodiment 1

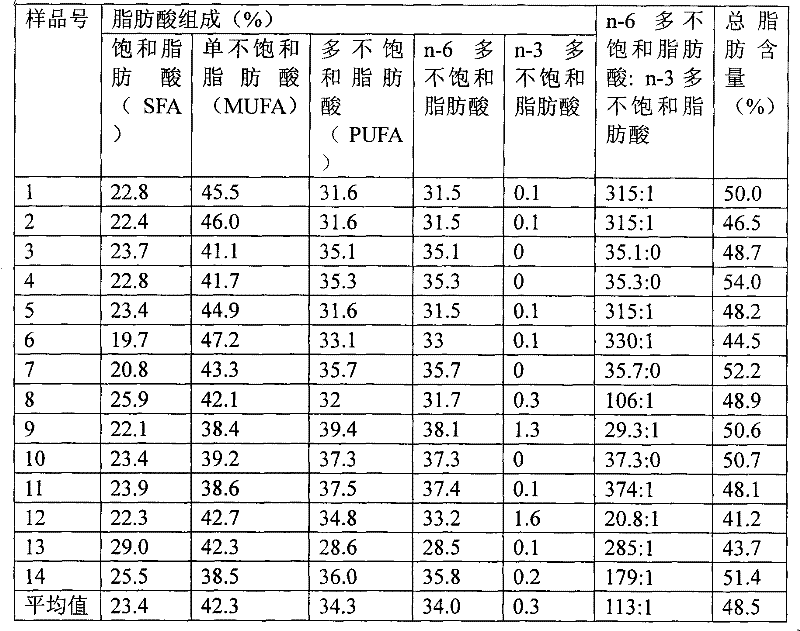

[0027] 100kg of peanut kernels are roasted at 140°C for about 25 minutes, with a suitable degree of burnt aroma. The roasted peanuts are immediately cooled to room temperature, and the broken red coat is blown away by the wind. And select the peanut kernels that have been removed from the burnt and red coat. Then, the peanut kernels are cold-pressed by a cold-pressing machine to obtain 39.3 kg of cold-pressed peanut oil and 60.7 kg of cold-pressed peanut meal. After testing, the fat content of cold-pressed peanut meal was 15.3%, and the fatty acid composition of cold-pressed peanut meal and cold-pressed peanut oil was shown in Table 3. The cold-pressed peanut meal and cold-pressed peanut oil prepared in this example were used as raw materials for the following examples.

[0028] The following examples selected vegetable oil and emulsifier as raw materials, and the emulsifier was monoglyceride. The selected raw material fatty acid composition test results are shown in Table 3...

Embodiment 2

[0032] The selected raw materials are 589.1g of cold-pressed peanut meal, 7.1g of cold-pressed peanut oil, 250.5g of first-grade rapeseed oil, 128.2g of first-grade safflower oil, and 25.1g of first-grade linseed oil.

[0033] After crushing the cold-pressed peanut meal in a mixer, add other materials, mix evenly, and then finely grind the mixture with a colloid mill to make the material fully mixed and stable, and put it into a bottle to obtain the finished peanut butter.

Embodiment 3

[0035] The raw materials selected are 596.2g of cold-pressed peanut meal, 52.3g of cold-pressed peanut oil, 22.0g of first-grade rapeseed oil, 176.4g of first-grade safflower oil, 74.3g of first-grade linseed oil, 68.8g of first-grade palm oil, and emulsifier. 10.0g.

[0036] After crushing the cold-pressed peanut meal in a mixer, add other materials, mix evenly, and then finely grind the mixture with a colloid mill to make the material fully mixed and stable, and put it into a bottle to obtain the finished peanut butter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com