High efficiency gradient dissolution and release fertilizer and production method

A fertilizer and gradient technology, applied in the direction of fertilizer mixture, fertilization device, application, etc., can solve the problems of low production level, low effective utilization rate, waste, etc., and achieve the effect of improving utilization rate, reducing labor intensity and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

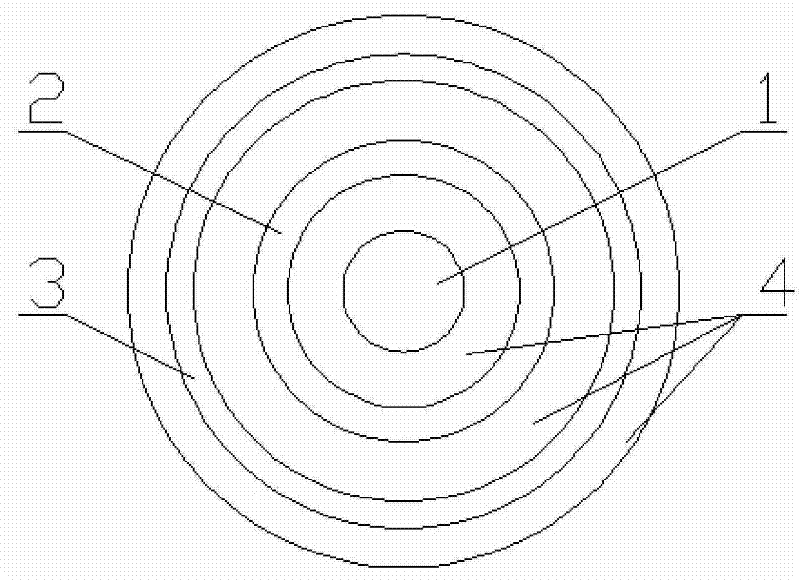

[0016] Embodiments of the invention. Efficient gradient release fertilizers, such as figure 1 As shown, according to the growth needs of the early, middle, and late stages of the crop, the late fertilizer granules 1 suitable for the late growth of the crops are produced first, and the late fertilizer granules 1 are placed in the partition slurry 4, and the entire late fertilizer granules 1 are wrapped, and then put into the mid-stage In the fertilizer 2, carry out rolling and sticking, repeat the above steps, and then wrap the partition slurry 4, the early stage fertilizer 3 and the partition slurry 4 in turn, and finally sterilize the partition slurry 4 and dry it at low temperature. For different crops, the fertilizers in the early, middle and late stages of the crops can be prepared according to the prior art using the fertilizers on the market.

[0017] The diameter of the late-stage fertilizer granules 1 made is preferably 3-10 millimeters, and the thickness of the mid-t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com