Fixture and clamp applying same

一种夹具、挂架的技术,应用在挂具结构领域,能够解决降低产能及工作效率、多空间、生产成本上升等问题,达到提高操作灵活性、降低生产成本、空间利用率高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

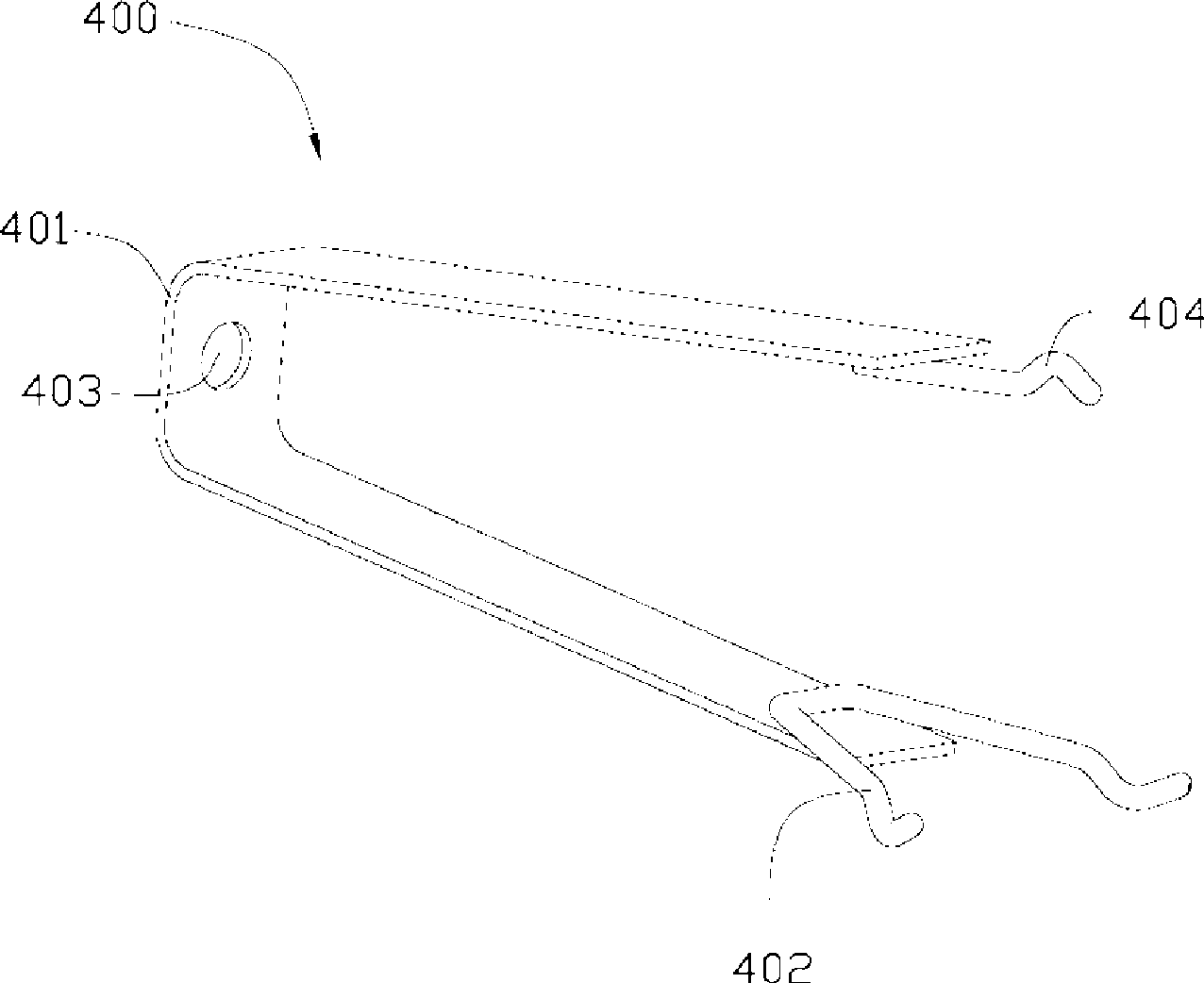

[0017] The preferred implementation mode of the clamp of the present invention is described by taking the structure of the hanger using the clamp as an example.

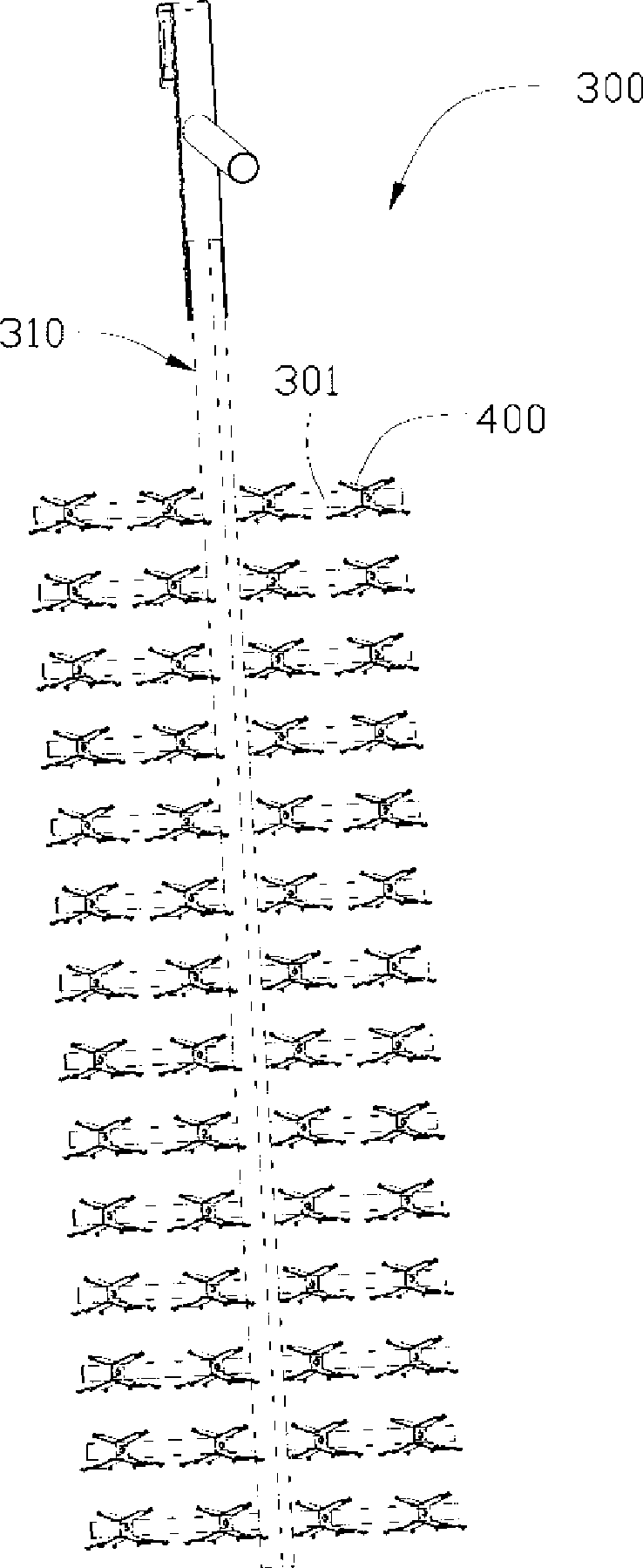

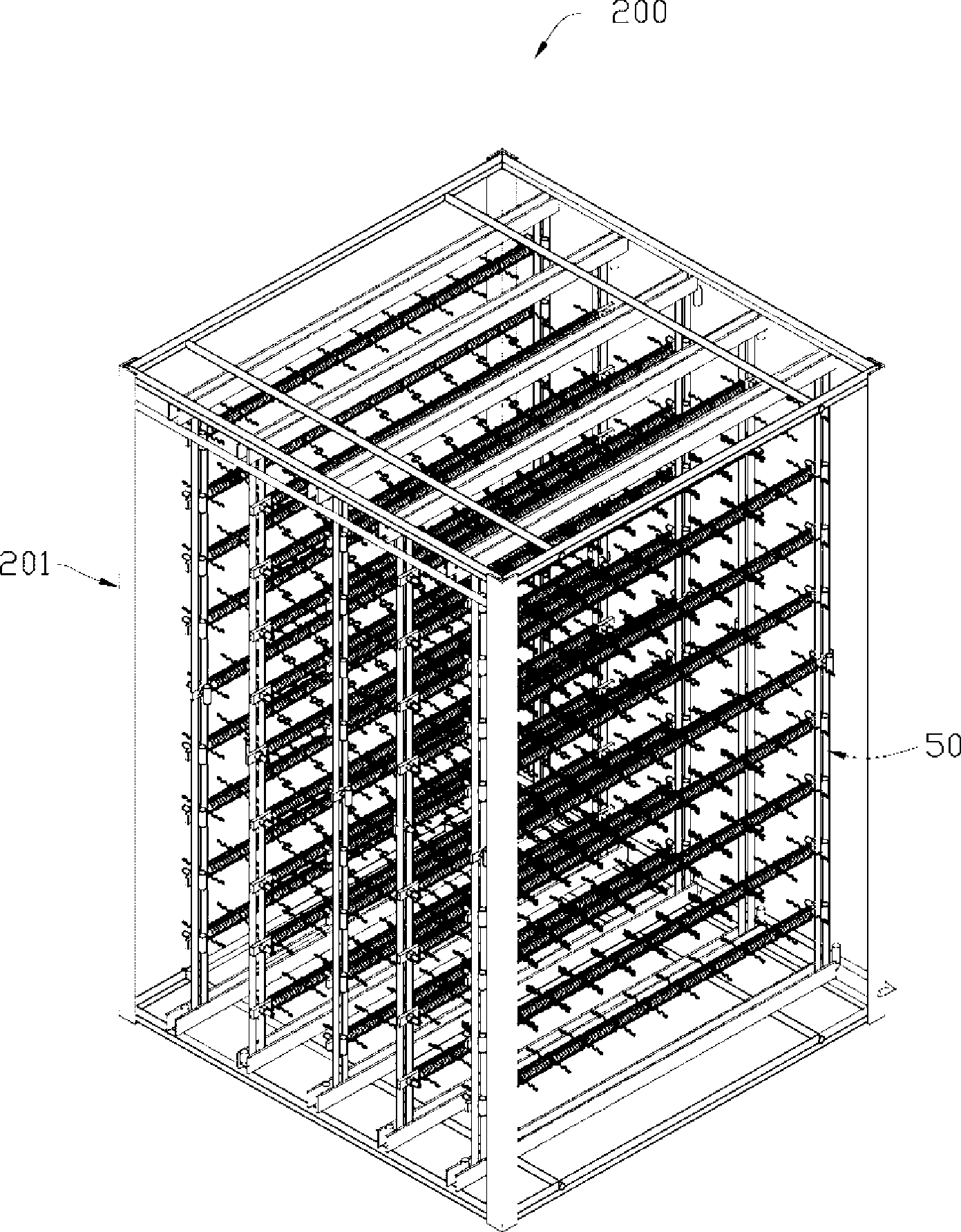

[0018] see image 3 , the hanger structure 200 includes a main body hanging frame 201 and multiple sets of hangers 50 , and the multiple sets of hangers 50 are clamped on the main body hanging frame 201 .

[0019] see Figure 4 The main hanging frame 201 includes a rectangular top frame 202 , a rectangular bottom frame 203 and four supporting vertical bars 2011 , 2012 , 2013 and 2014 . The four corners of the rectangular top frame 202 and the rectangular bottom frame 203 are respectively fixedly connected with the two ends of the support vertical bars 2011 , 2012 , 2013 and 2014 to form the main hanging frame 201 .

[0020] The rectangular top frame 202 includes four frames 2021 , 2022 , 2023 , 2024 , two poles 2025 , 2026 and multiple sets of clamping structures 2018 . The ends of the four frames 2021 , 2022 , 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com