Fountain solution composition for lithographic printing and heat-set offset rotary printing process

A lithographic printing and fountain solution technology, applied in printing, printing surface preparation, printing device and other directions, can solve the problem of not paying attention to the improvement of blanket ink accumulation, and achieve good printing performance, inhibit ink accumulation, and easy adjustment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8 and comparative example 1~9

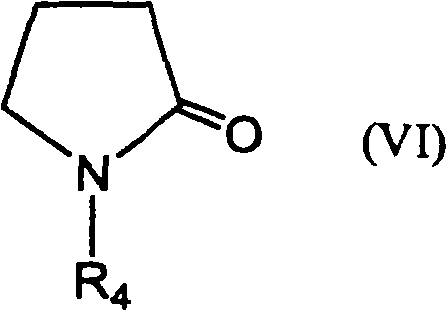

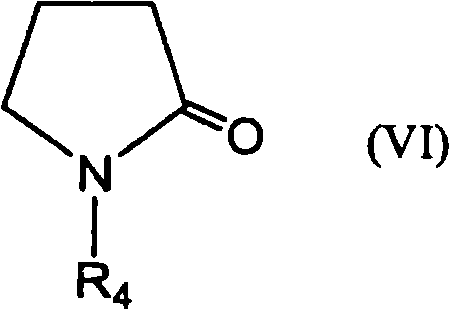

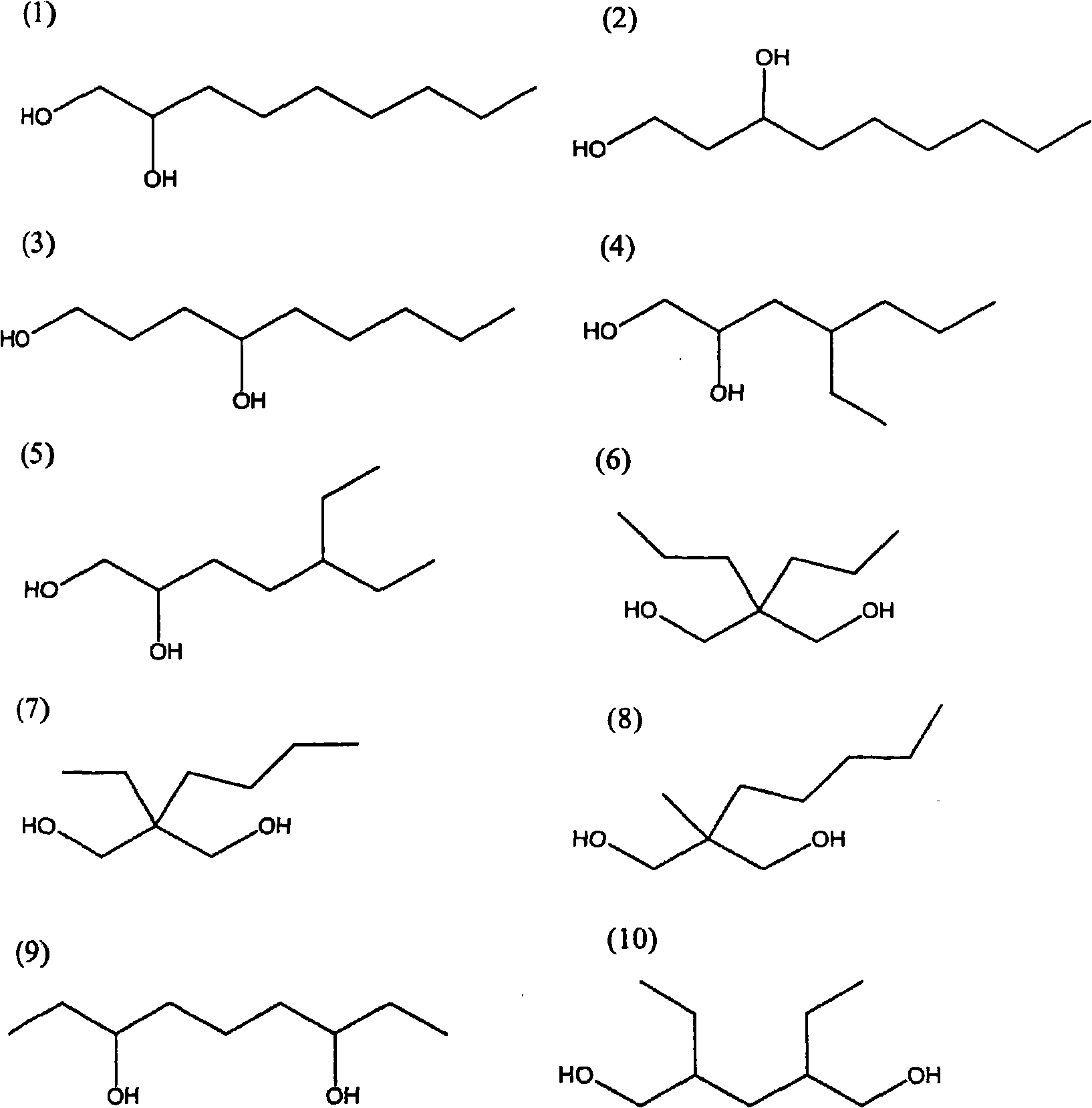

[0129] Except for changing the diol compound according to the following Table 1, use equal mass and exactly the same operation to prepare various fountain solution compositions according to the following formulas. In this formulation, the unit is gram, and it is the addition amount in the case of adding water at the end and adjusting to 100g, and it has the same meaning as mass %.

[0130] Formulation of fountain solution composition (use solution) when used

[0131] Ingredients Amount

[0132] Propylene glycol mono-n-butyl ether 0.5g

[0133] Propylene glycol 0.5g

[0134] Glycol compound 0.3g of table 1

[0135] Carboxymethylcellulose 0.01g

[0137] Citric acid 0.02g

[0138] 2,2-Dibromo-2-nitroethanol 0.002g

[0139] 2-Methyl-5-chloro-4-isothiazolin-3-one 0.002g

[0140] Benzotriazole 0.001g

[0141] Add water to reach 100g

[0142] For each fountain solution composition, a Lithron 26 printing machine manufactured by KOMORI Co., Ltd....

Embodiment 9~18

[0165] Exactly the same operation was carried out except that propylene glycol mono-n-butyl ether and propylene glycol in Example 6 were replaced with the compounds in Table 2 below. In Example 18, isopropanol was used and its addition amount was increased to 15 times (ie, 7.5%) that of the compound used in other examples (0.5%). In Example 18, unless the amount of isopropanol was increased in this way, even if the amount of water was increased, the ink would adhere to the non-image portion of the printed matter, and staining tended to occur. The results are shown in Table 2.

[0166] Table 2

[0167] Example

Compound 1

Compound 2

dot area

Reduction rate (%)

Feed roller contamination

6

Propylene glycol mono-n-butyl ether

50

5

○

9

Ethylene glycol mono-n-butyl ether

56

8

○

10

Ethylene glycol mo...

Embodiment 19~25

[0171] Exactly the same operation was carried out except that propylene glycol mono-n-butyl ether and propylene glycol in Example 5 were replaced with the compounds in Table 3 below. The results are shown in Table 3.

[0172] table 3

[0173] Example

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com