High-pure magnesium preparation method and apparatus

A preparation device and high-purity technology, which is applied in the field of vacuum distillation to prepare high-purity magnesium, can solve the problems of unsatisfactory production and use, and achieve the effects of simple structure, simple operation and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the examples, but not as a limitation to the present invention.

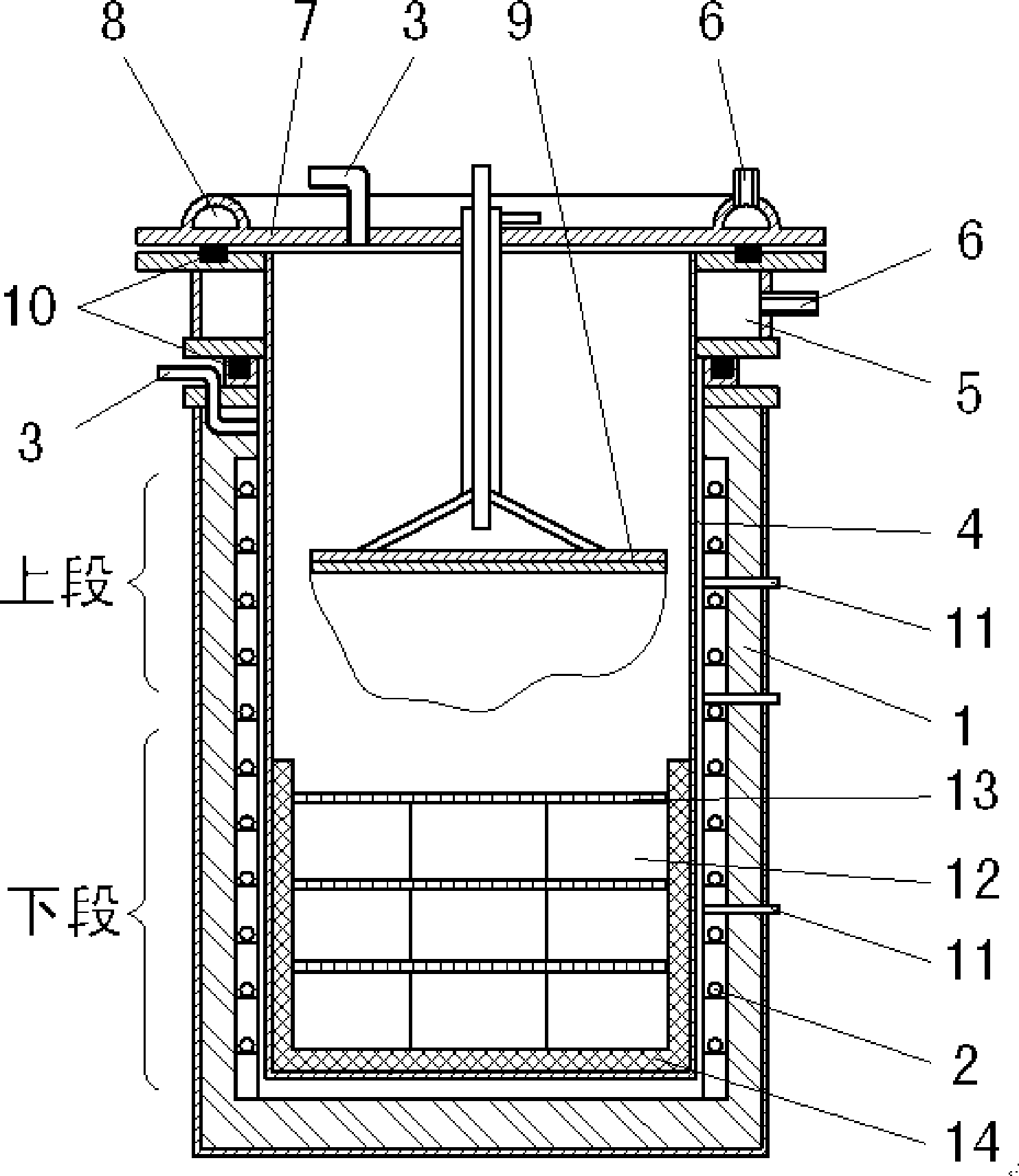

[0021] Embodiments of the invention. A preparation method of high-purity magnesium. Such as figure 1 shown. A preparation method of high-purity magnesium. The method uses magnesium ingot 12 as a raw material to produce high-purity magnesium with a purity equal to or higher than 99.98%; the steps are as follows:

[0022] a), the φ 300 * 130mm magnesium ingots placed in the graphite crucible 14 are divided into three layers and 5 pieces per layer are placed in the vacuum distiller 4, and an aluminum plate 13 is placed on each layer of magnesium ingots; then the vacuum distiller is put into a vacuum Distillation furnace 1;

[0023] b), vacuumizing between the vacuum distiller 4 and the condenser 9 and between the vacuum distiller 4 and the vacuum distillation furnace 1;

[0024] c), heating the vacuum distillation furna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com