Shoe, in particular sports shoe

A technology for sports shoes and shoe uppers, applied to shoes, can solve problems such as the difference of unfavorable use performance, and achieve the effect of improved manipulation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

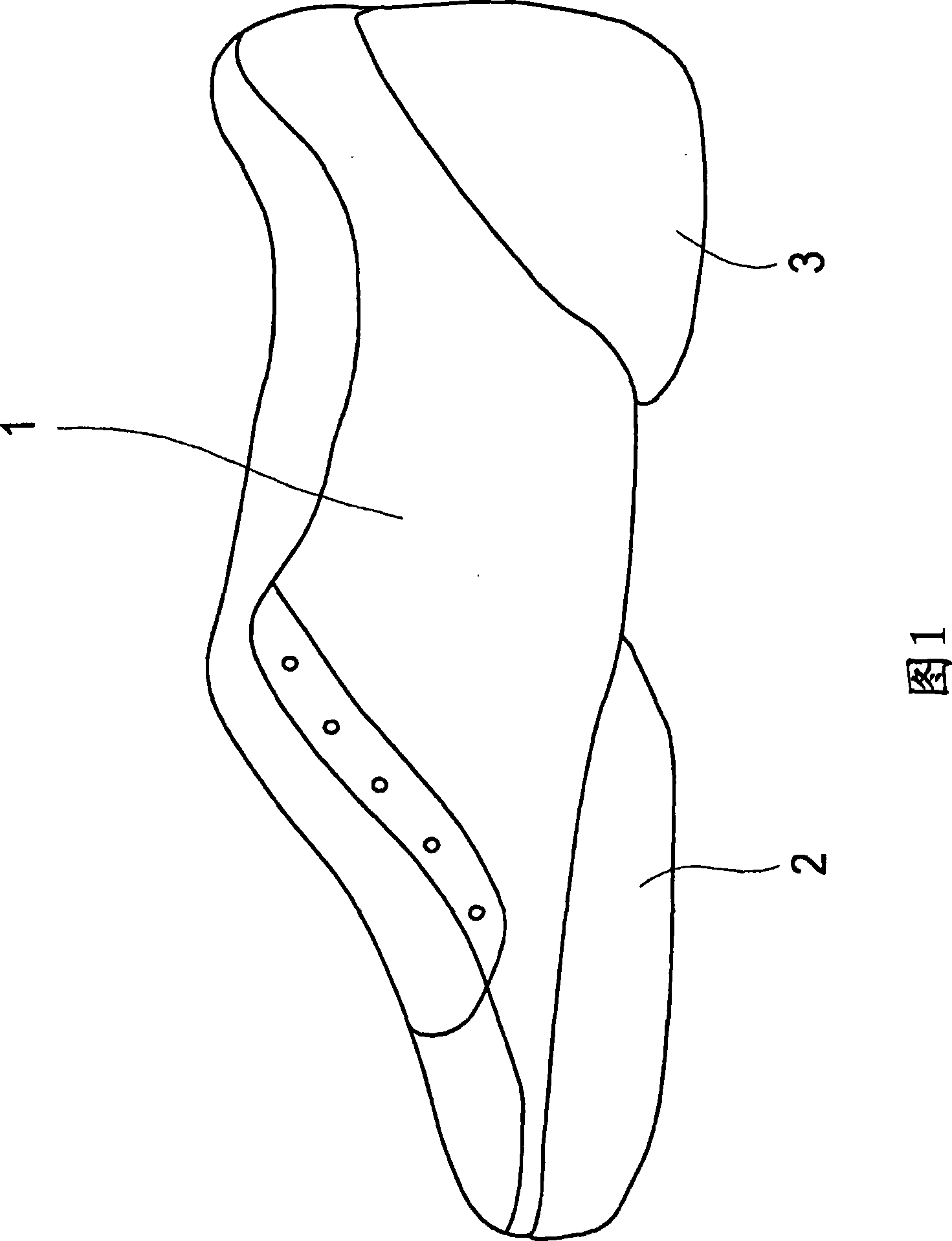

[0034] In FIG. 1 a shoe, ie a sports shoe, is shown. The shoe has a shoe upper 1 in a known manner. It has a two-part sole part 2, 3: a sole part 2 is arranged in the forefoot region of the shoe, and a sole part 3 is arranged in the rear part region of the shoe.

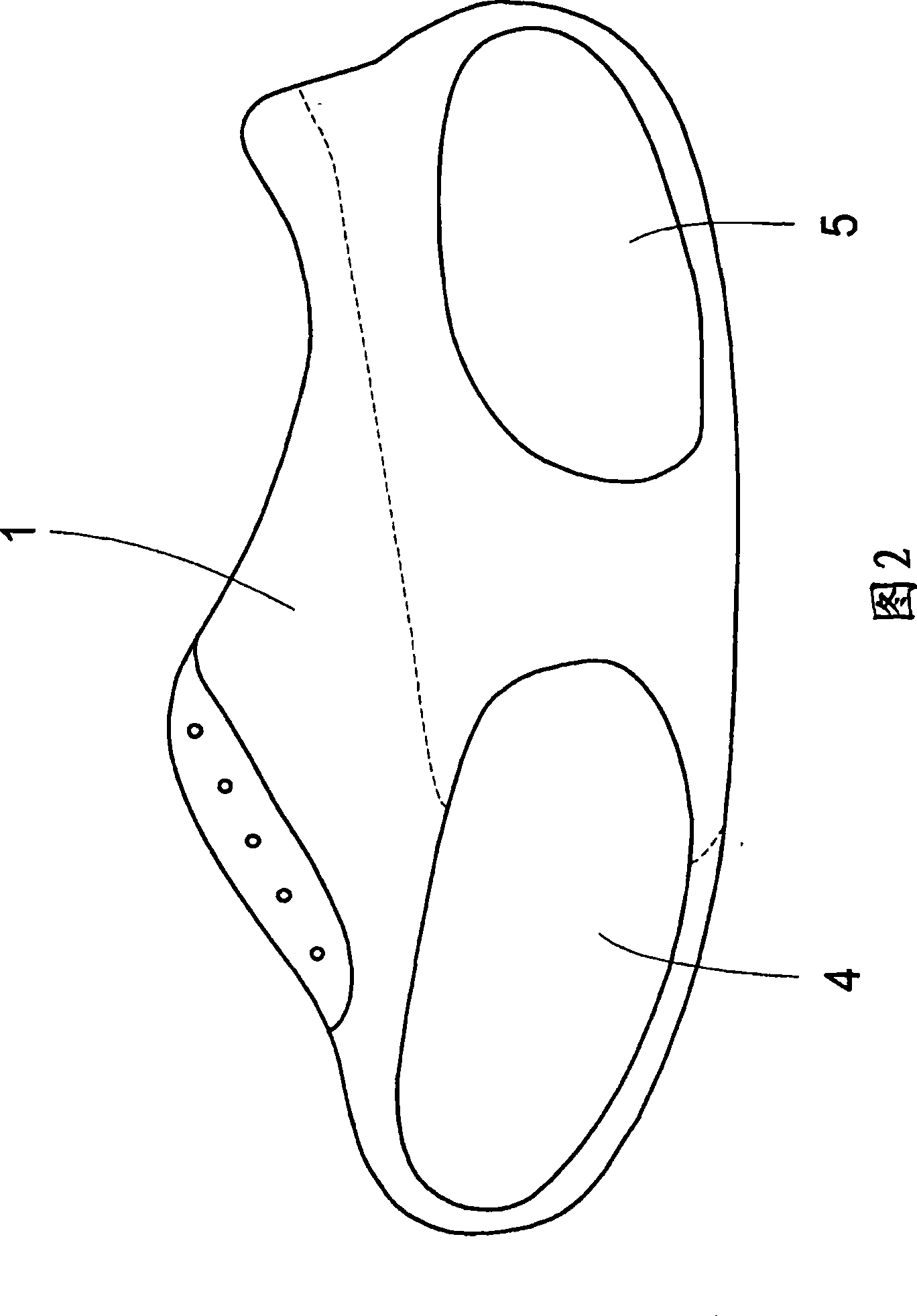

[0035] FIG. 2 shows a shoe upper 1 without sole parts 2 , 3 . As can be seen, the upper 1 has cutouts 4 and 5 which correspond to the shape and size of the sole parts 2 , 3 . That is to say, according to the invention, the upper 1 has at least two cutouts 4, 5 in the area facing the bottom, wherein the size and shape of the cutouts 4, 5 correspond to the dimensions of the sole parts 2, 3 in their contact area with the upper 1 and shape. The sole parts 2 , 3 are inserted into or over the cutouts 4 , 5 and then remain connected to the upper 1 .

[0036] This connection can be achieved by seaming, welding, gluing or similar methods, combinations of which are also conceivable.

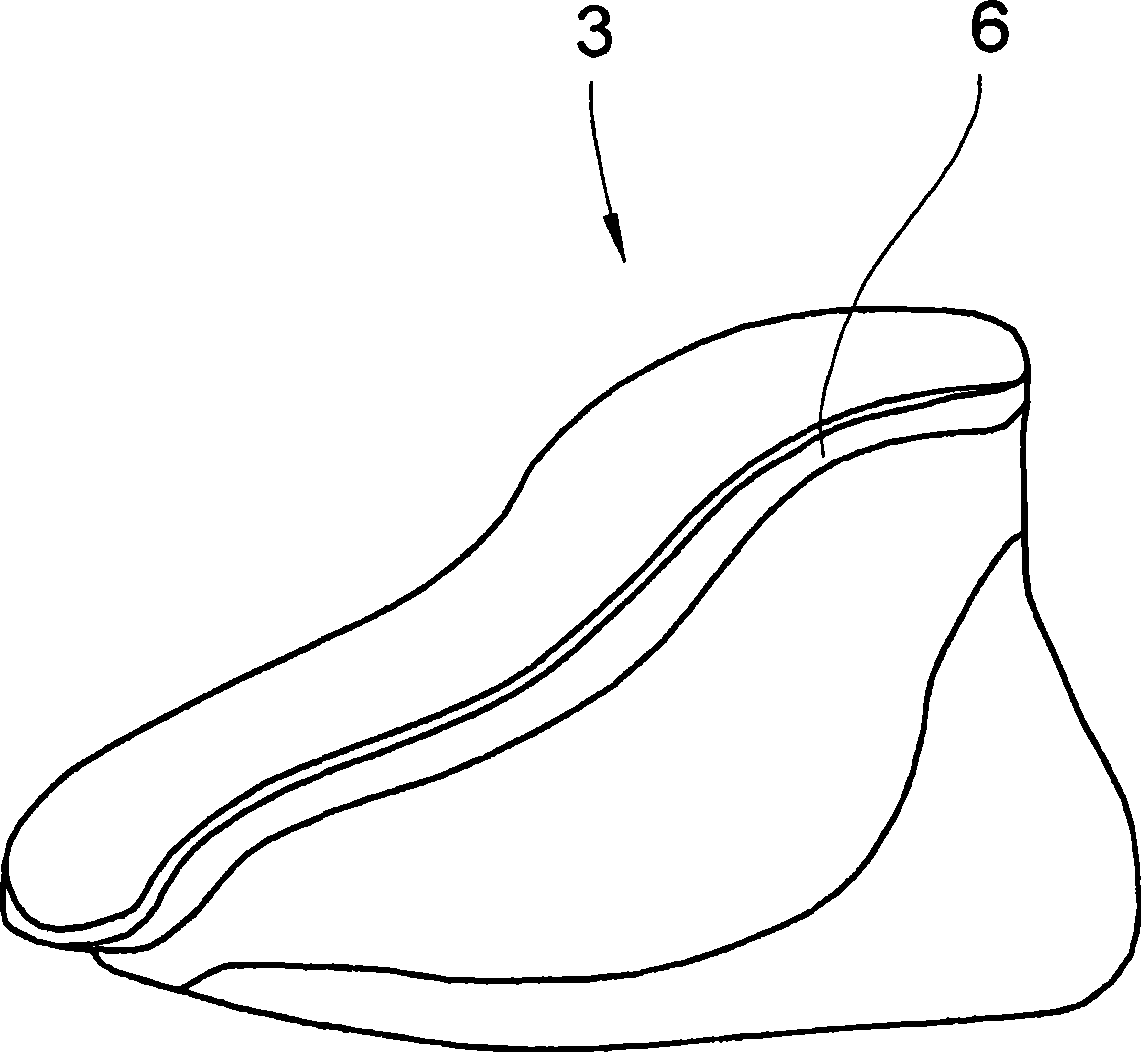

[0037] exist image 3 The sole part 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com