Improved print control strips for measuring colour on printed material

A technology for printing quality and control bars, applied in the direction of using color charts for color measurement, printing, printing presses, etc., can solve problems such as non-optimal color adjustment, and achieve the effect of accurate color adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

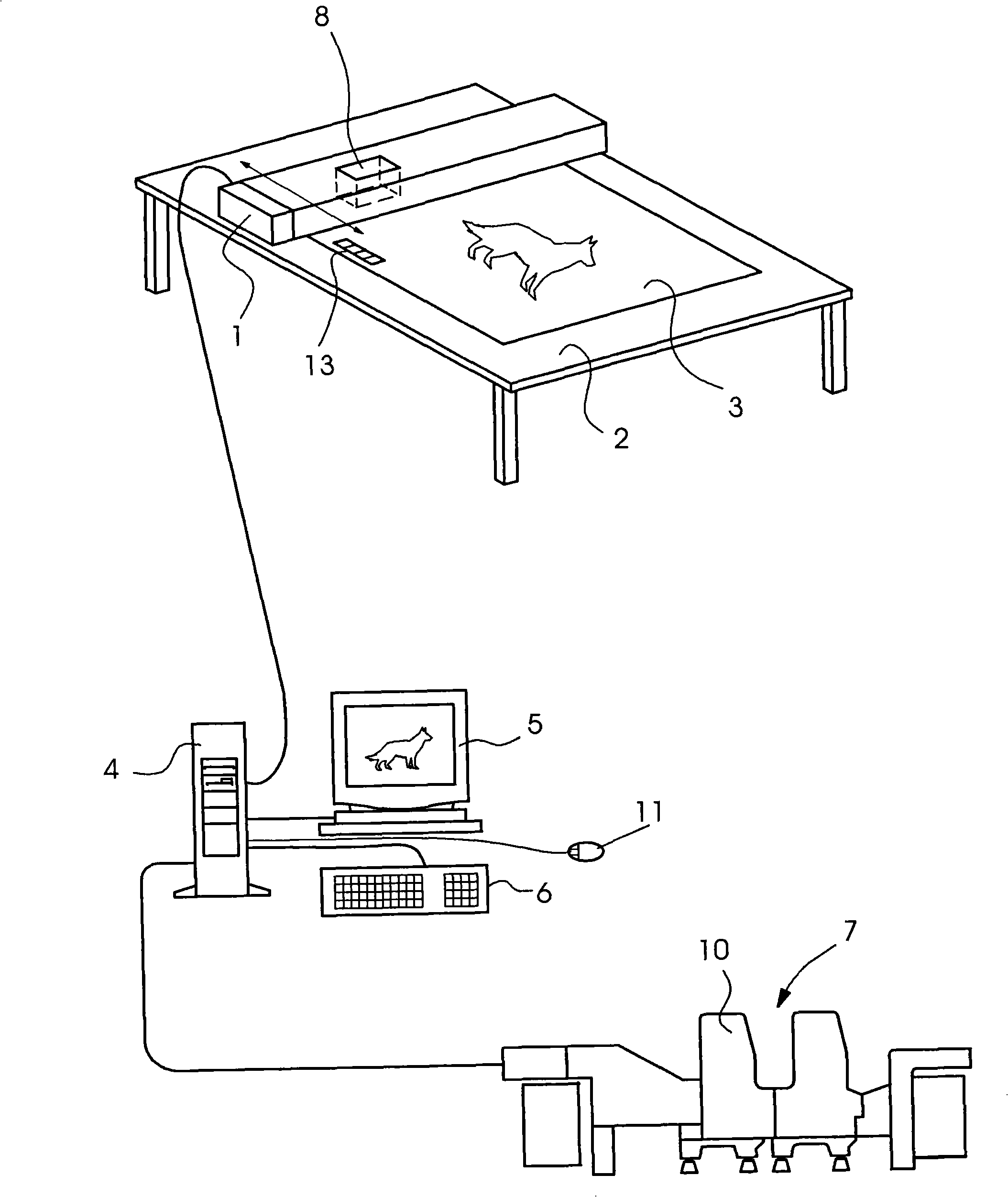

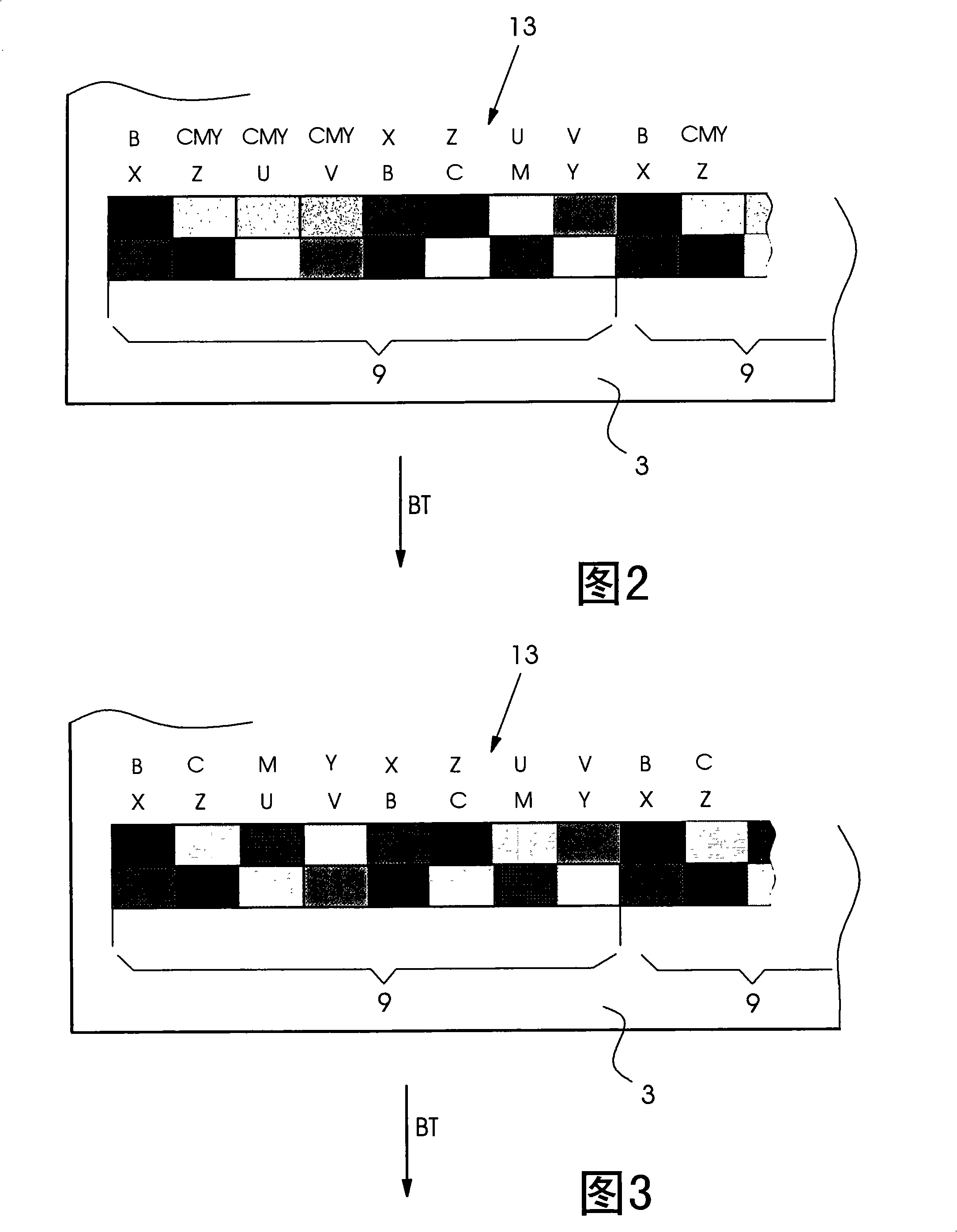

[0023] figure 1 The color control circuit shown in includes a color measuring device 1 , a computer 4 and ink metering devices in a printing unit 10 of a printing press 7 . Said devices 1, 4, 7 are networked with each other by means of an electronic communication link. Color measuring device 1 in figure 1 In this case, a separate color measuring device is configured as a separate color measuring device with a measuring table 2 for receiving the produced printing material 3 . Instead of the separate color measuring device 1, it is also possible to use a so-called in-line color measuring device integrated in the printing press 7, which measures the printing material in the printing press 7, preferably at the output of the last printing unit 10. 3 for testing. figure 1 The separate color measuring device 1 has a measuring beam that can move in the longitudinal direction of the substrate 3 and a color measuring head 8 that can move in the transverse direction of the substrate 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com