Method for supporting a weft guide element

A technology of yarn guides and conductive elements, applied in textiles and papermaking, looms, textiles, etc., can solve problems such as weakening performance and fabric quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

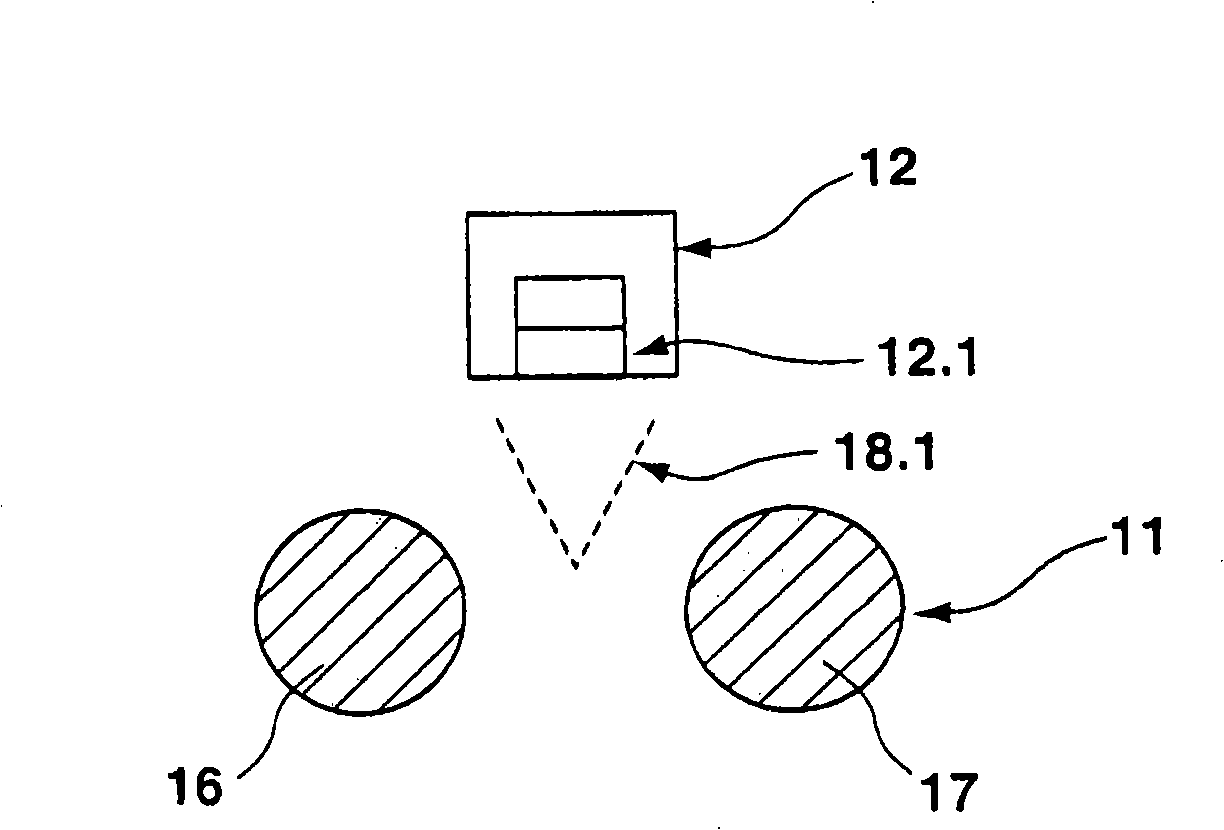

[0042] Figure 1 shows the weft thread guide area of a loom 10 with a guide groove 11 for a weft thread guide element 12 which is not shown more explicitly in Figure 1 , but which can in particular be obtained from figure 2 see. The loom 10 is double-sided weft insertion and is therefore equipped with acceleration devices 13, 13', weft selectors 14, 14' and braking devices 15, 15' on both sides of the guide groove 11. The guide channel 11 is located completely below the shed, not shown here. Furthermore, pre-charge chambers 29 , 29 ′ for the acceleration means 13 , 13 ′ can be seen, the function of which will be described in detail below with reference to FIG. 3 .

[0043] figure 2 The structure of the guide channel 11 of the weaving machine 10 in FIG. 1 is shown and thus its function is shown more clearly. A channel 11 is formed by two parallel bars 16 , 17 between which said channel 11 encloses a space 18 with an approximately V-shaped cross-section. The weft thread gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com