Weighing mechanism of electronic scale bale-reopening machine

A technology of weighing mechanism and electronic scale, which is applied in the direction of weighing equipment, weighing and measuring devices for materials with special properties/forms, which can solve the problem of large weighing weight, affecting the quality of finished non-woven fabrics, and affecting different fibers. Raw material ratio and other issues to ensure the effect of weighing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

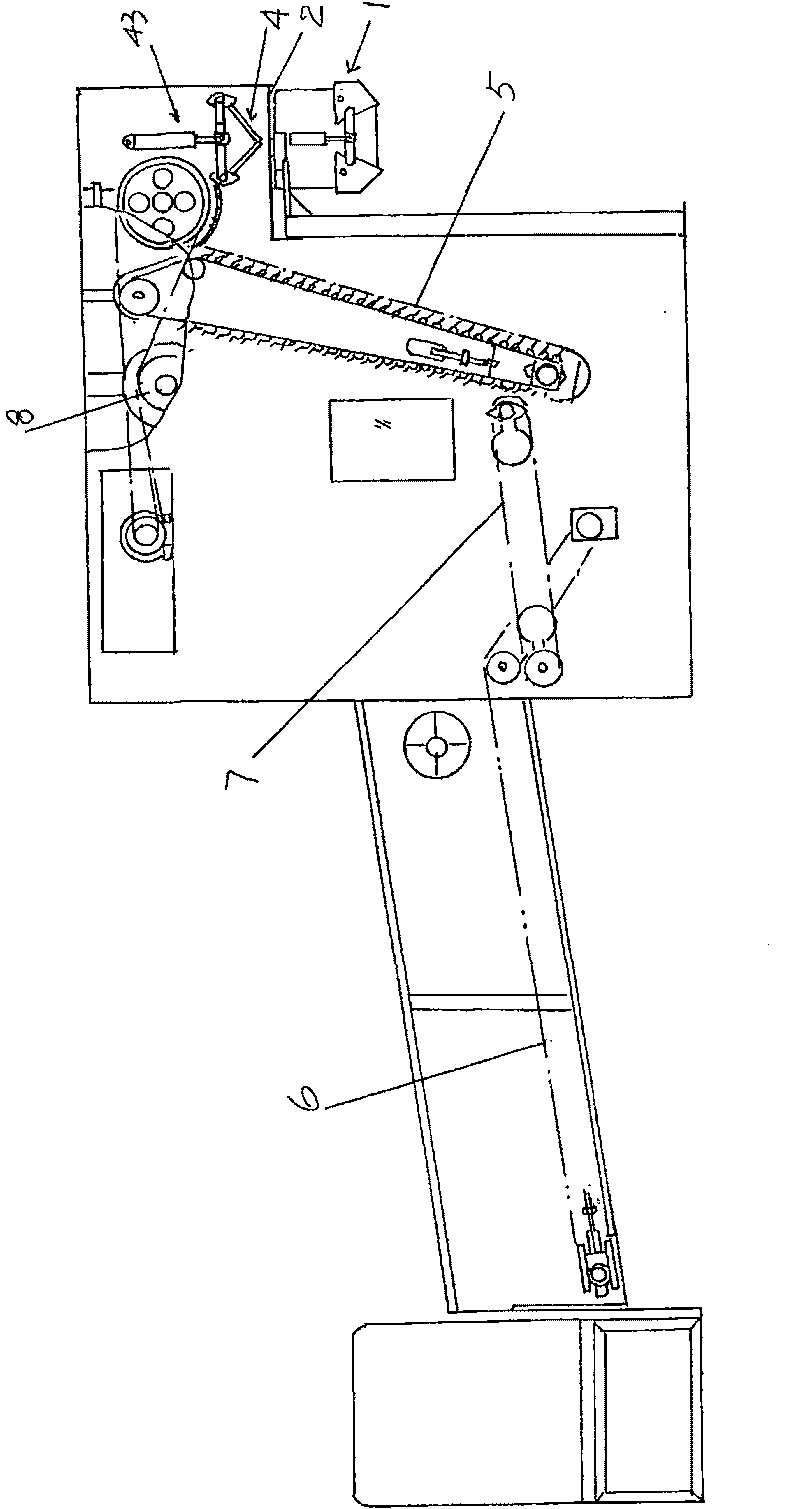

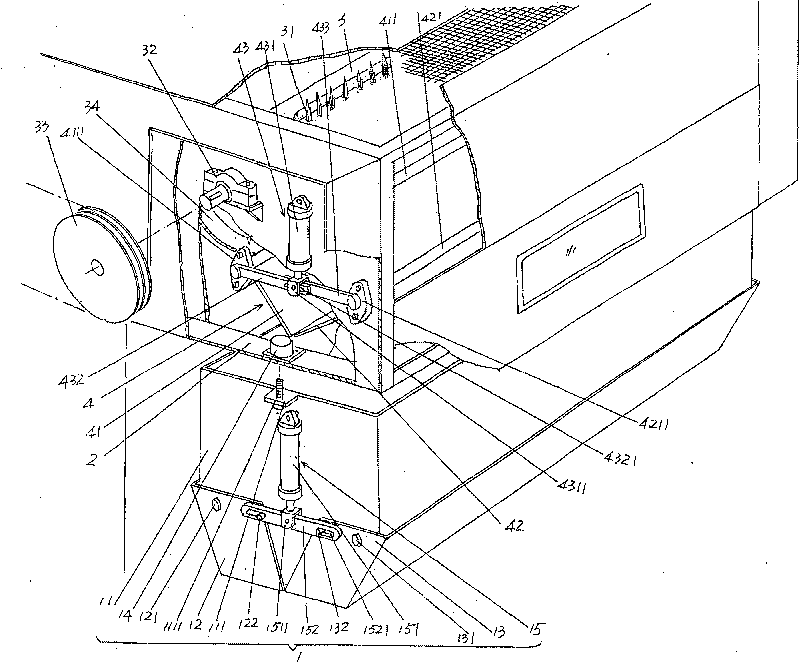

[0017] Please refer to figure 1 , provides the frame 2 of the electronic weighing bale opener, on the top of the frame 2, a cotton stripping roller 3 is rotatably set through a pair of bearing seats 32 with the corresponding wall body in the length direction of the frame 2 as a carrier , on the roller body of the stripping roller 3 and along the length direction of the roller body, brad nails 31 are arranged. For lifting brad curtain 5 ( figure 2 Shown) the non-woven fiber that is transported is picked up in the cotton-feeding groove 34, and then drives to weighing bucket 1.

[0018] As the gist of the technical solution of the present invention, an isolation device 4 is provided below the stripping roller 3 and above the weighing bucket 1 , more specifically between the stripping roller 3 and the weighing bucket 1 . The specific structure of the preferred but not absolutely limited isolation device 4 is as follows: a pair of first and second windshield doors 41, 42 are con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com