Vibration damping test device possessing dry damping structure vane

A damping structure and vibration reduction test technology, applied in the testing of machine/structural components, measuring devices, vibration testing, etc., can solve the problem of difficulty in accurately predicting the vibration response of the damper with dry friction damper.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings.

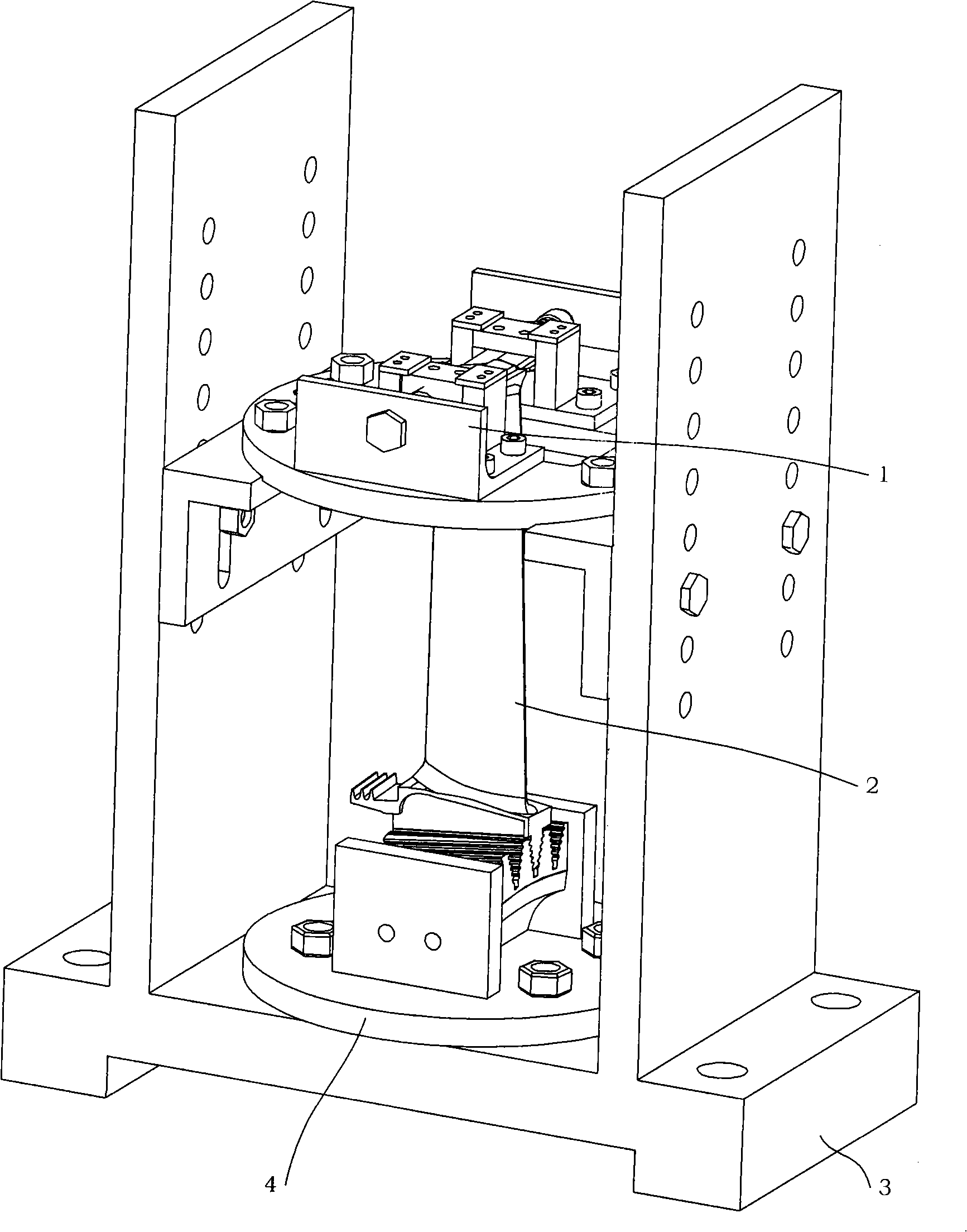

[0045] A test device for a blade with a dry friction damping structure of the present invention is composed of a positive pressure loading assembly 1, a clamp assembly 4 and a base 3,

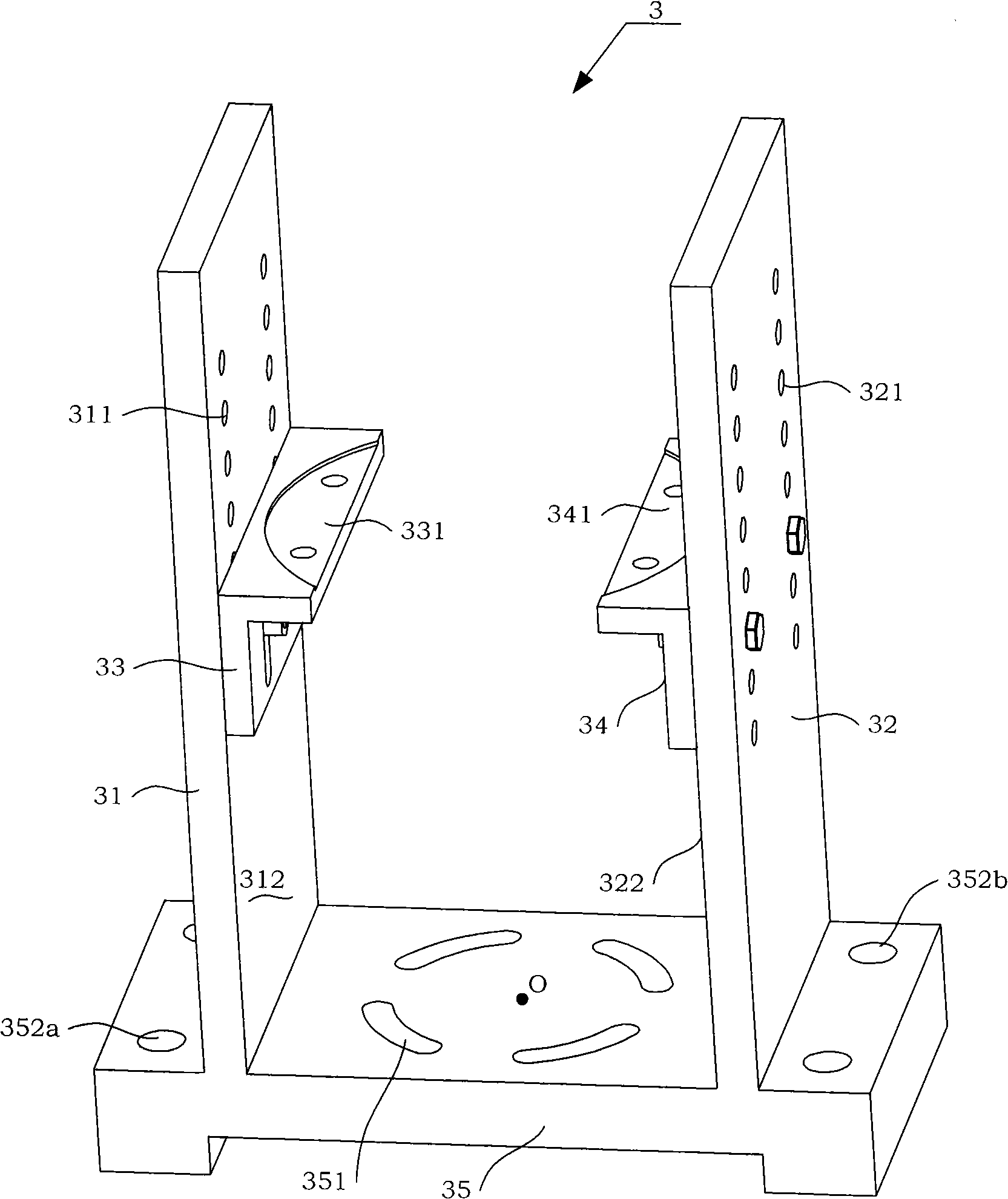

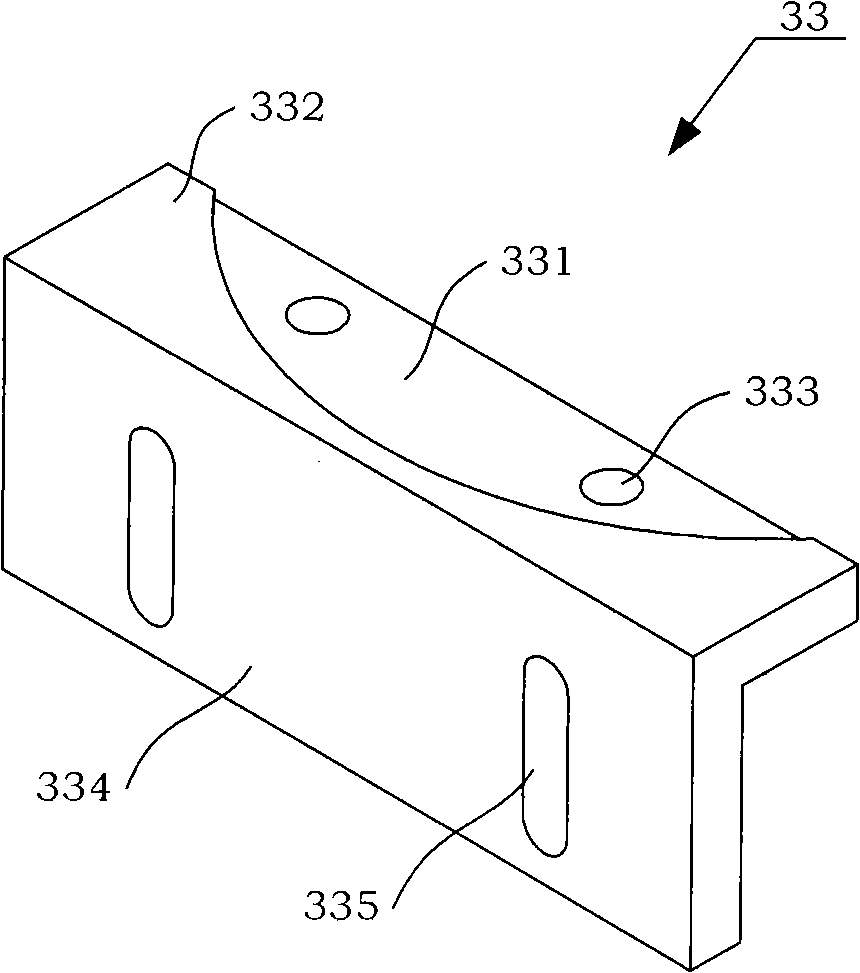

[0046] see figure 2 As shown, the base 3 includes a base frame, an L-shaped left support plate 33, and an L-shaped right support plate 34; the base frame is an integral molding, and the base plate 35 of the base frame has a left support plate 31 and a right support plate 32;

[0047] The left support plate 31 is provided with a plurality of A positioning holes 311, and the A positioning holes 311 are used to install the L-shaped left support plate 33 on the B face 312 of the left support plate 31 through the cooperation of the screw and the nut, and the L-shaped left support plate 31 The support plate 33 is placed opposite to the L-shaped right support plate 34;

[0048]The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com