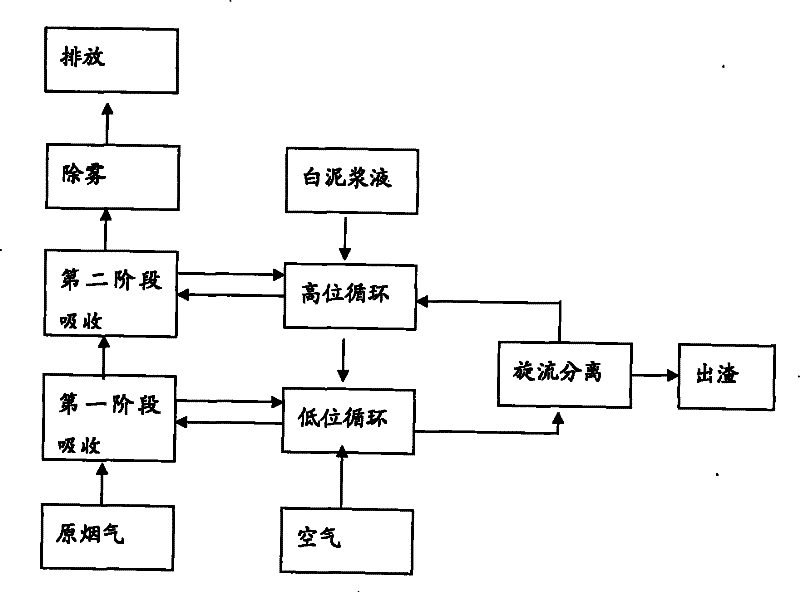

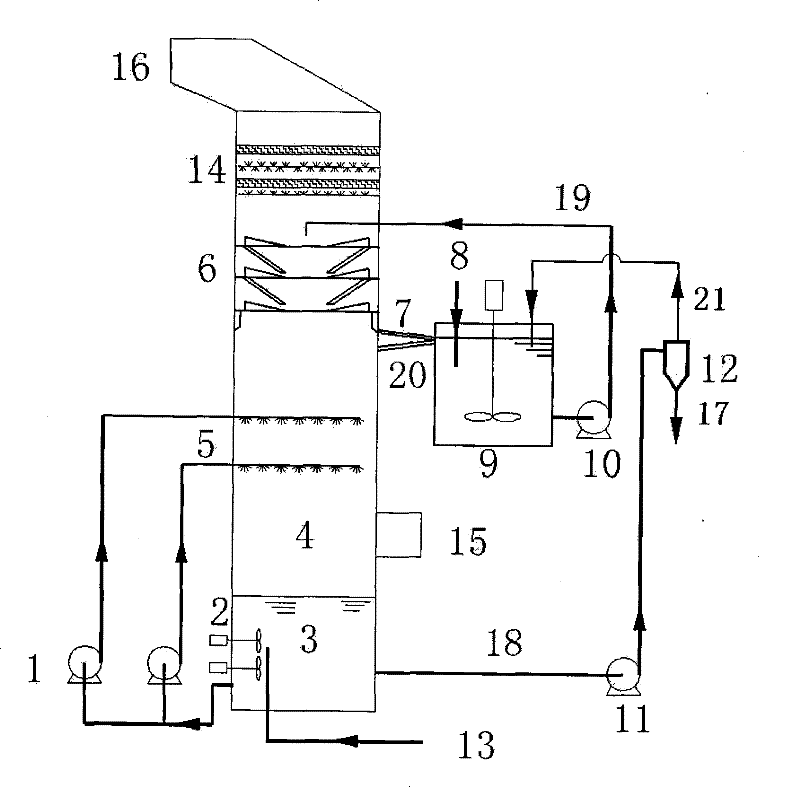

Method for removing sulfur dioxide in flue gas with white slime and device

A technology of sulfur dioxide and flue gas, which is applied in the direction of chemical instruments and methods, separation methods, and separation of dispersed particles, can solve the problems of not fully considering the characteristics of white mud, and achieve the effect of improving the desulfurization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In a paper mill, 8 sets of 75t / h fluidized bed boilers adopt this process for desulfurization, the pH value of the first stage is controlled at 5.0, and the liquid-gas ratio is selected at 6L / m 3 , the pH value of the second stage is controlled at 6.8, and the liquid-gas ratio is selected as 2L / m 3 , imported sulfur dioxide concentration 4600mg / m 3 , the outlet sulfur dioxide concentration is 182 mg / m 3 , The purity of gypsum reaches 91%.

Embodiment 2

[0023] In a paper mill, two 130t / h pulverized coal furnace boilers adopt this process for desulfurization, the pH value of the first stage is controlled at 5.1, and the liquid-gas ratio is selected at 4L / m 3 , the pH value of the second stage is controlled at 6.5, and the liquid-gas ratio is selected as 2L / m 3 , imported sulfur dioxide concentration 2800mg / m 3 , the outlet sulfur dioxide concentration is 154 mg / m 3 , The purity of gypsum reaches 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com