Fast rotation device for winch band axis

A fast-rotating, shaft-driven technology, which is applied to motor vehicles, transportation and packaging, and vehicles used for freight, can solve the problems of laborious and time-consuming winch operation, low binding efficiency, and human finger damage, etc., and achieves convenient use and binding high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

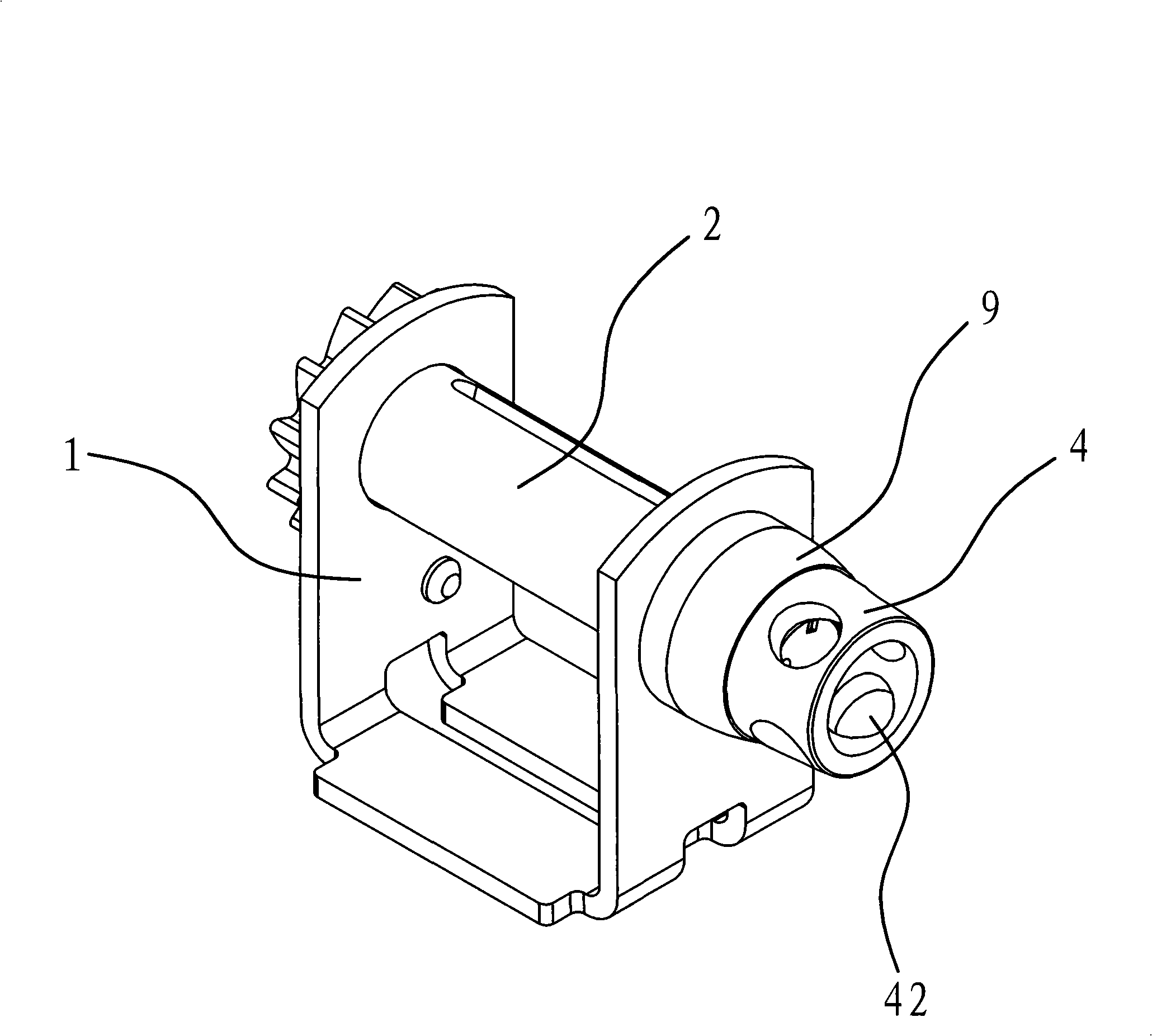

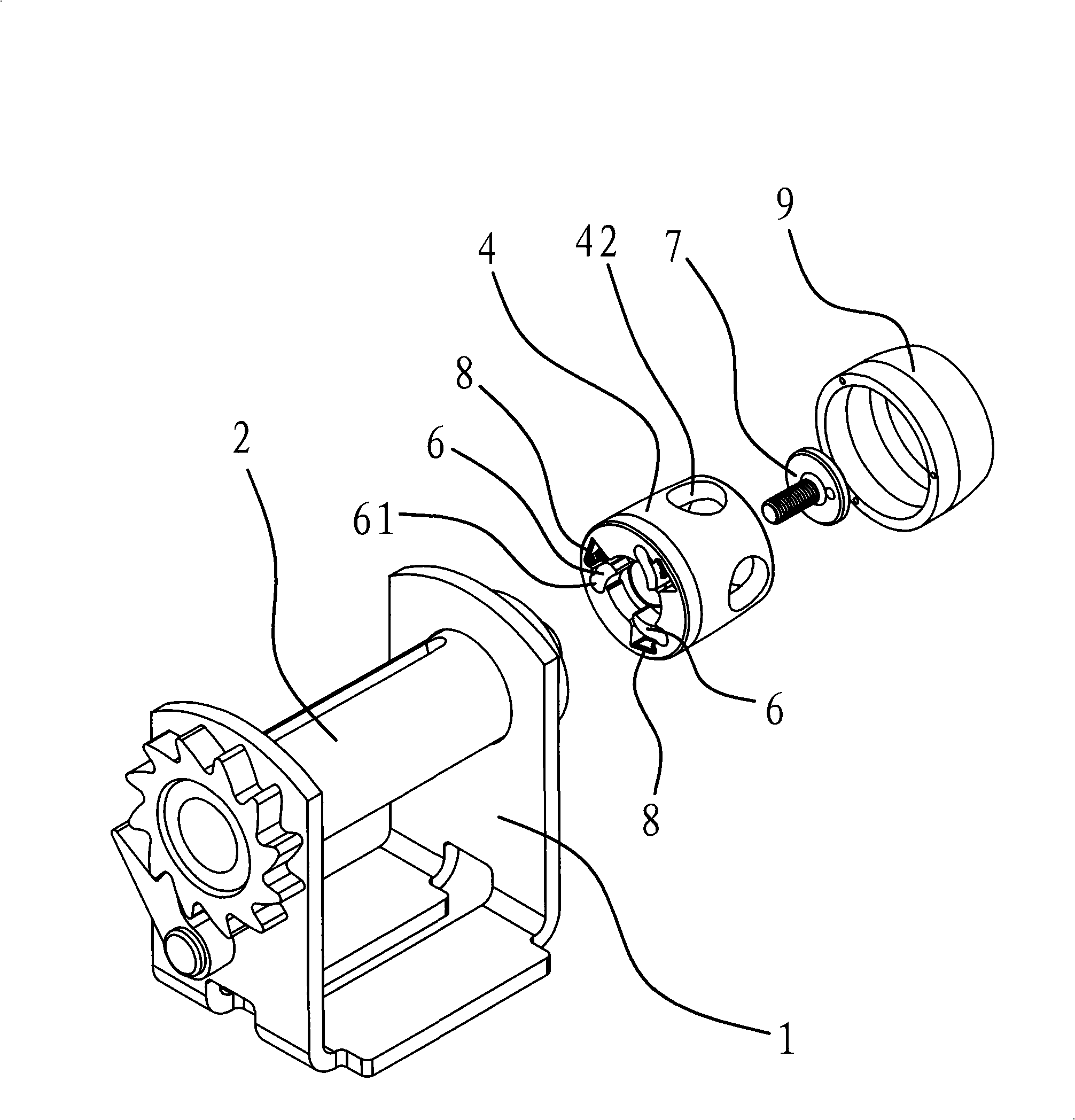

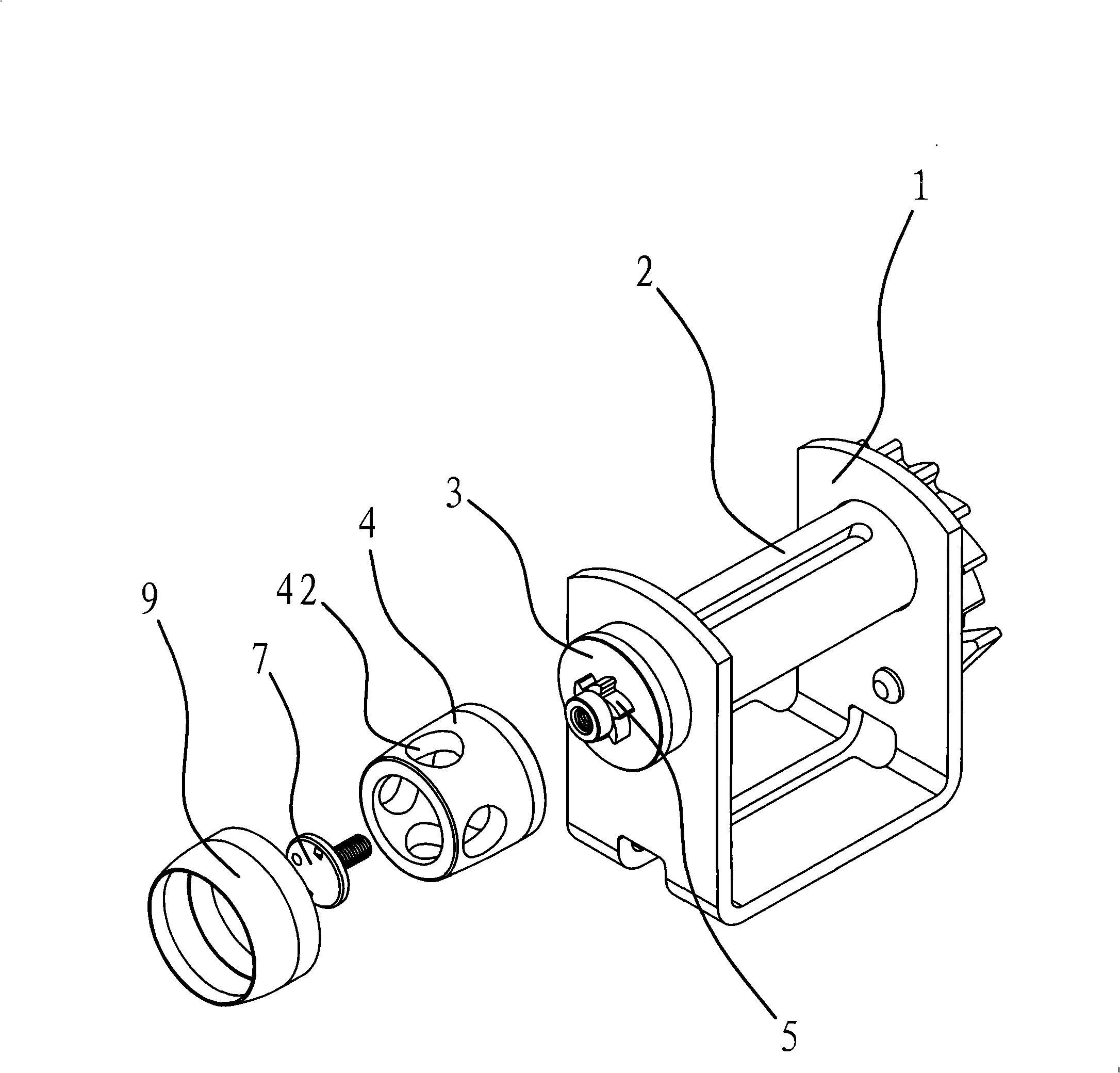

[0029] The winch includes a winch support 1, a belt shaft 2 and a binding belt and the like. The belt shaft 2 is connected to the winch support 1, and the belt shaft 2 can rotate around its axial direction, and the binding belt is wound on the belt shaft 2.

[0030] Such as figure 1 and figure 2 and image 3 and Figure 4 Shown, the fast turning device of this winch band shaft is located at the band shaft 2 extension end of winch support 1 side. This device comprises fixed seat 3, rotating body 4, ratchet 5 and ratchet 6 etc., and fixed seat 3 is fixedly connected in belt shaft 2 ends, and ratchet wheel 5 is fixedly connected in fixed seat 3 ends. The rotating body 4 is cylindrical, the inner end of the rotating body 4 is sleeved on the side of the fixed seat 3 and the rotating body 4 covers the above-mentioned ratchet 5, and the side at the outer end of the rotating body 4 has four evenly distributed Crowbar hole 42. In this embodiment, a set screw 7 is arranged betwee...

Embodiment 2

[0038] The structure and principle of this embodiment are basically the same as those of Embodiment 1, except that the slot 41 has only one retaining edge 41a, and the inner end of the ratchet 6 abuts against the slot under the elastic force of the elastic member 8 41, the inner end of the ratchet 6 cannot be disengaged from the slot 41 under the double action of the stop edge 41a and the elastic member, so that the outer end of the ratchet 6 is against the ratchet 5, see Figure 6 shown. Of course, such a structure can also make the ratchet 6 swing around its inner end.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com