At-sea composite foundation

A hybrid and basic technology, applied in infrastructure engineering, water conservancy engineering, artificial islands, etc., can solve the problems of difficult placement of cylindrical foundations and insufficient pull-out resistance, and achieve weight reduction, improved pull-out resistance, and reduced costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

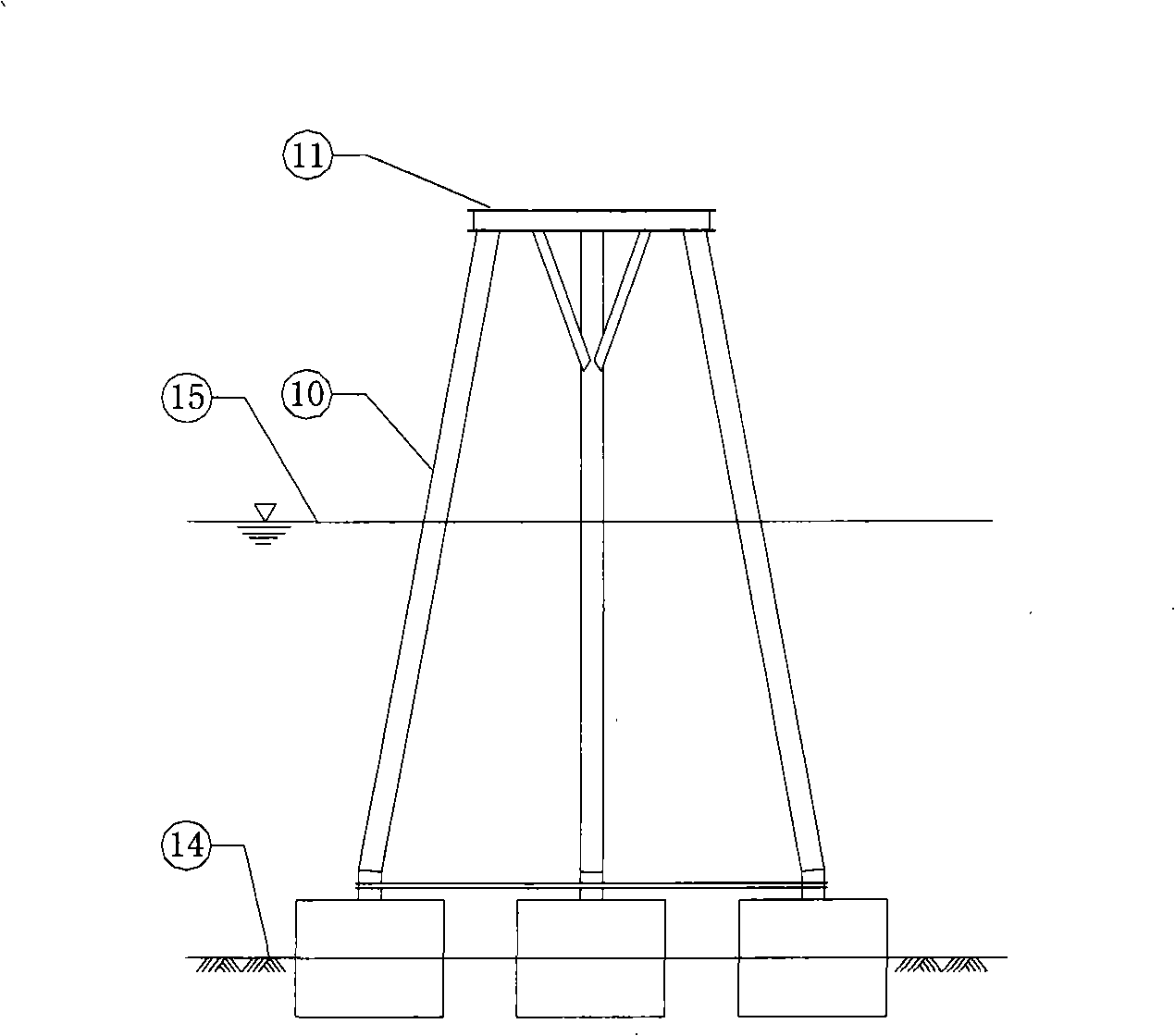

[0014] Such as figure 1 As shown, the typical representative of the column-supported structure-the platform structure adopts a mixed foundation, and a mixed foundation is connected under 10 platform columns. In the case of high surface soil bearing capacity, the top surface of the mixed foundation is higher than the seabed mud surface 15, see image 3 .

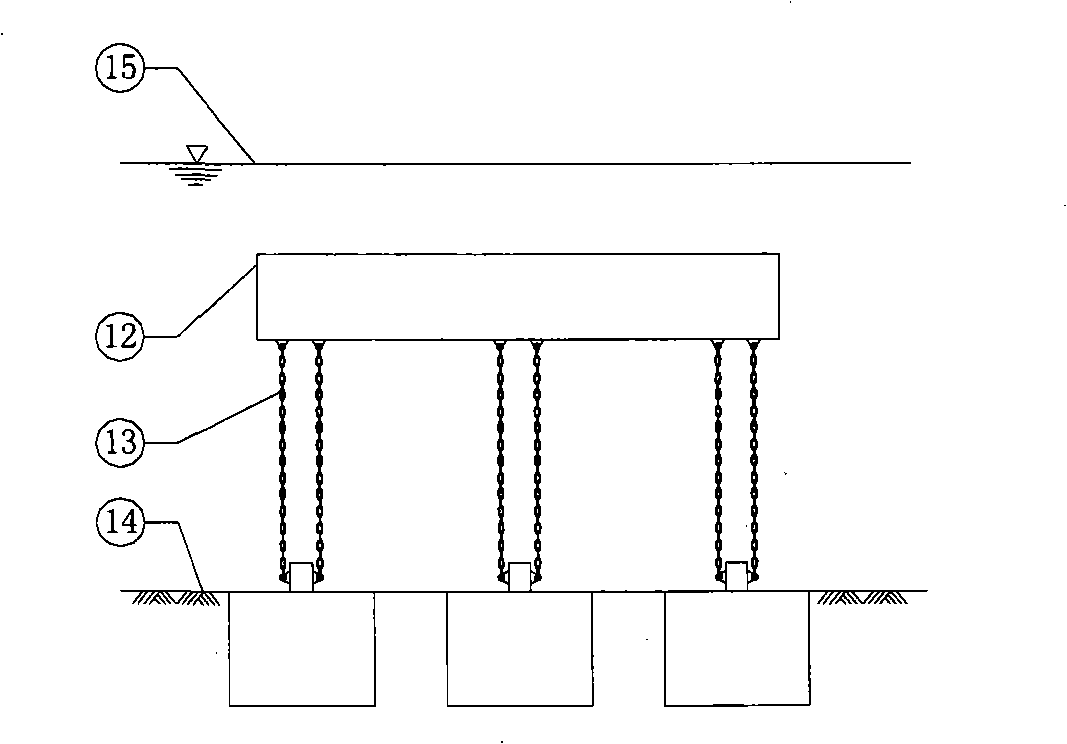

[0015] Such as figure 2 As shown, the typical representative of the floating structure - the tension leg buoy structure adopts a mixed foundation, and each mixed foundation cylinder is connected by two anchor chains 13. When the bearing capacity of the surface soil is low, the mixed foundation Buried below the seabed mud surface 15 or flush with the seabed mud surface 15, see Figure 4 .

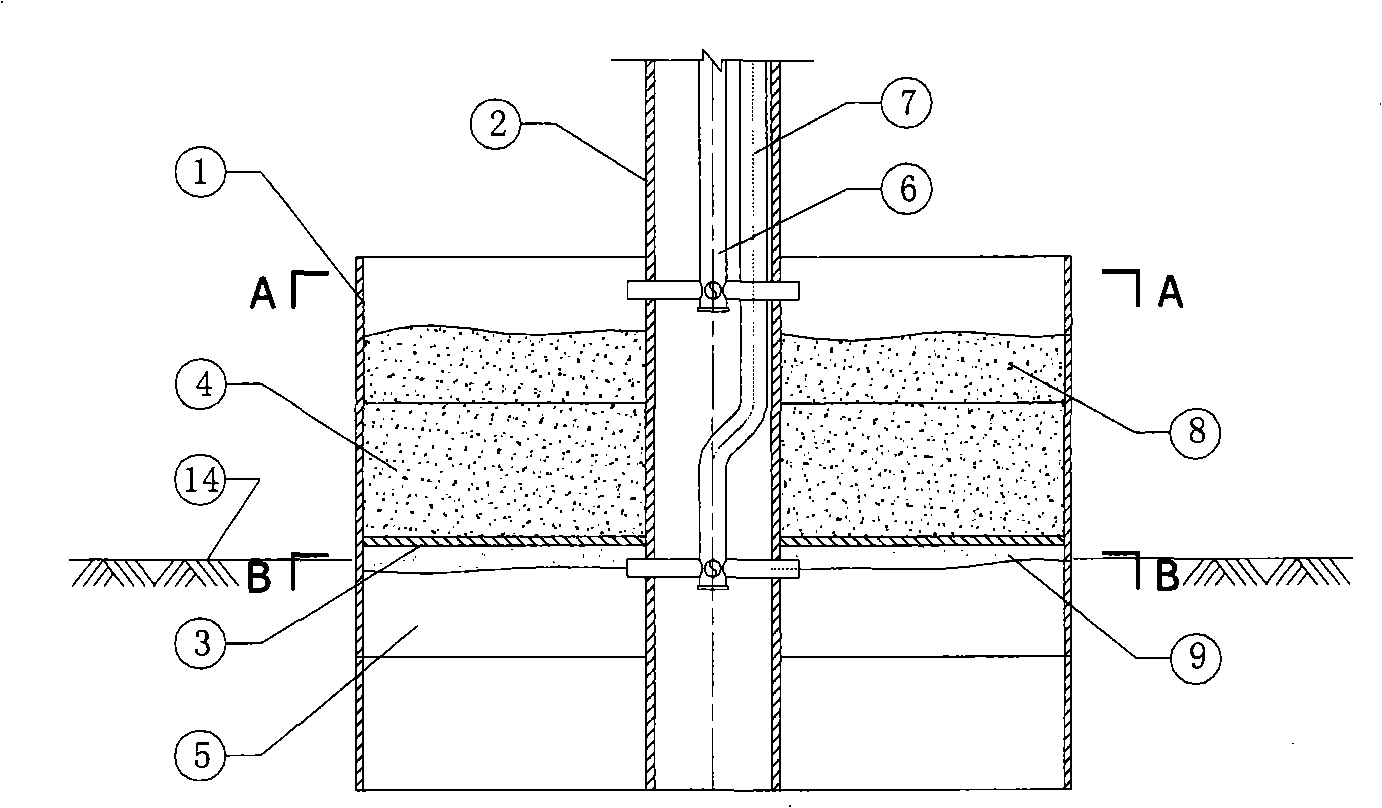

[0016] For the structure of the hybrid foundation, see image 3 , Figure 4 , Figure 5 box Figure 6 , the cylinder wall 1 and the center column 2 are connected to form an integral steel structure through a partition 3, an upper r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com