Method for separating lignocellulose-containing biomass with methanoic acid

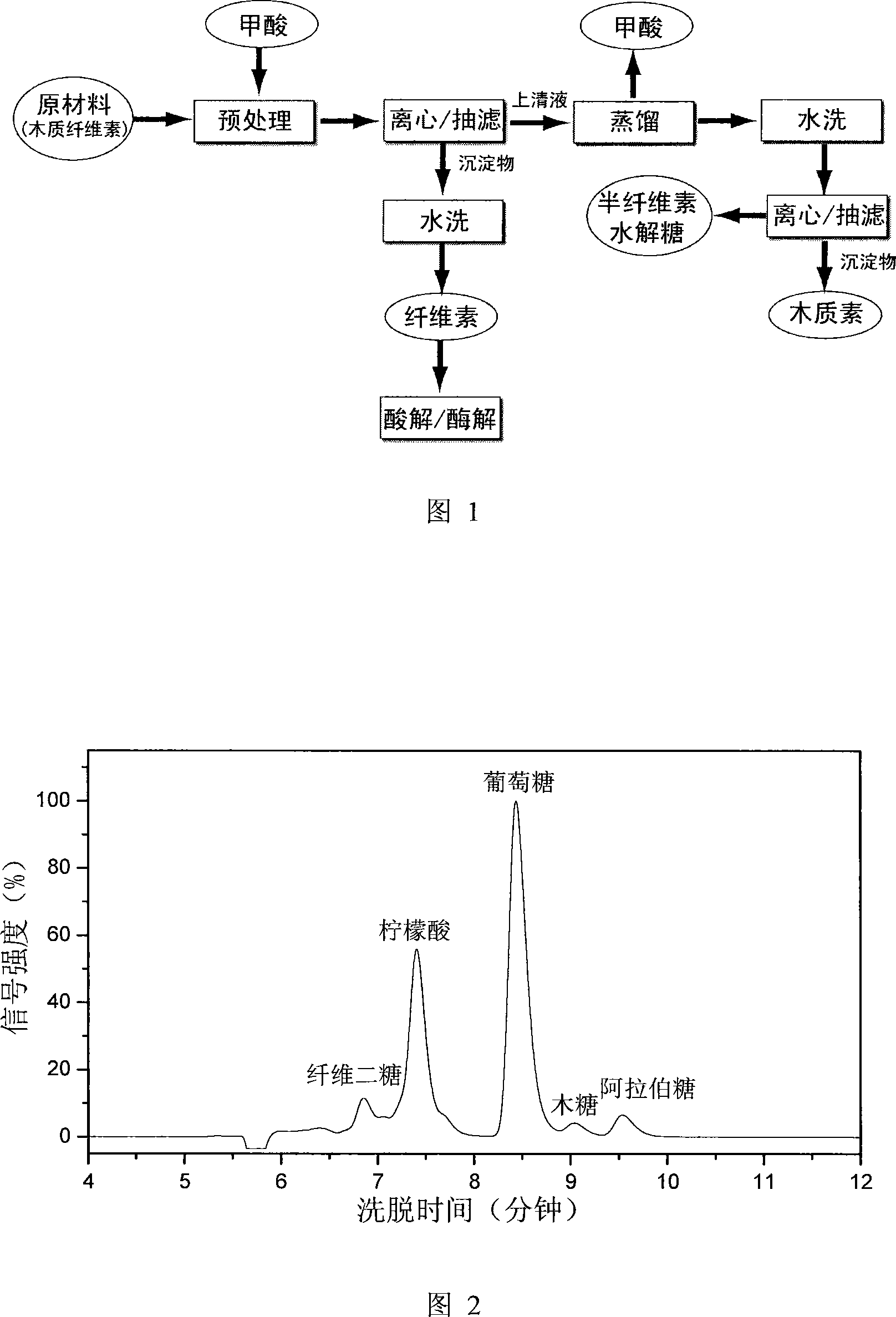

A technology of lignocellulose and lignin, which is applied in the field of separating lignocellulose-containing biomass into lignin, separating lignocellulose-containing biomass, hemicellulose and cellulose components, and can solve the problem of increased operational difficulty etc. to save energy, achieve solvent recovery, and achieve high concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

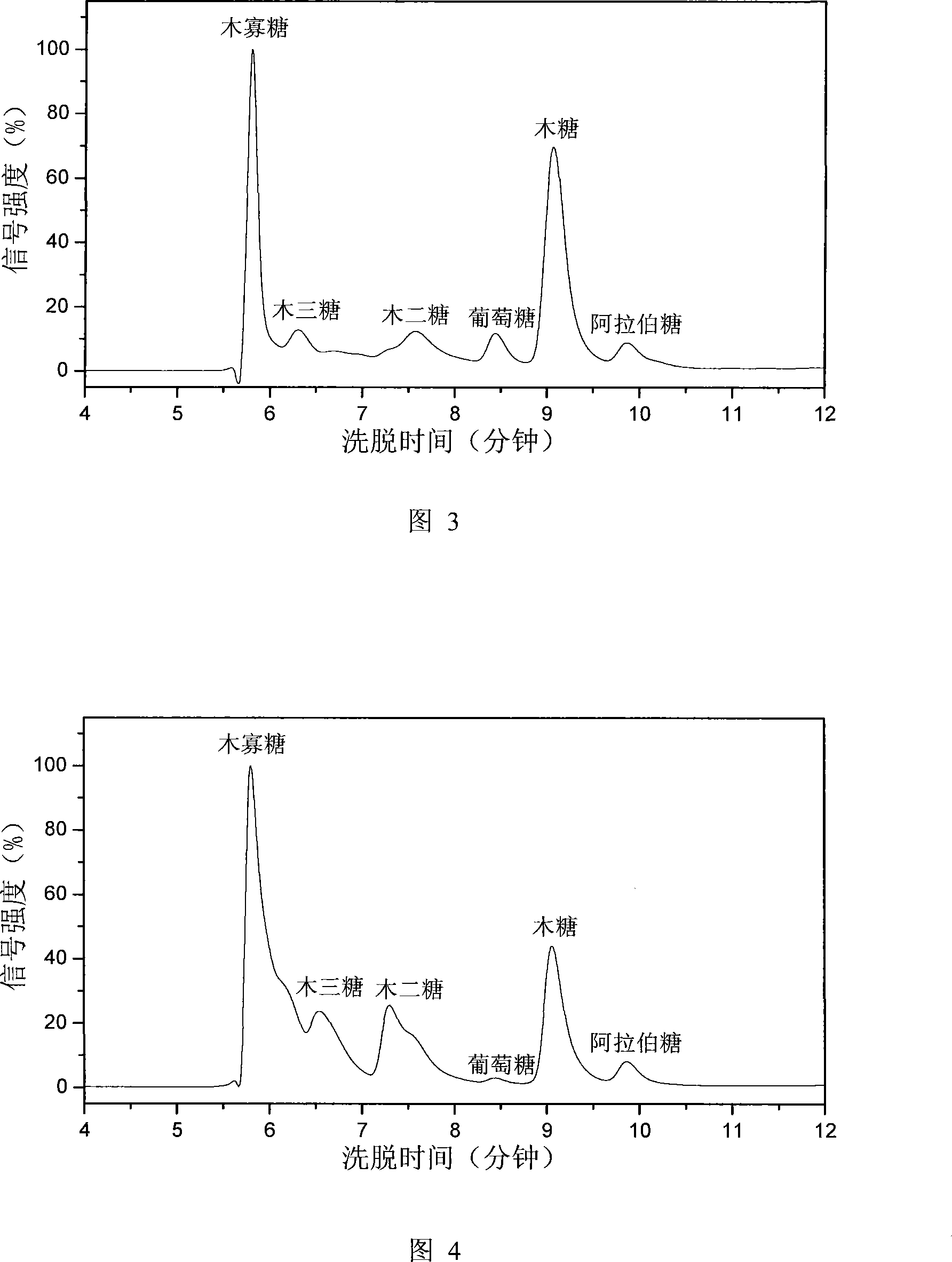

Embodiment 1

[0030] The corn stalks are crushed, and the material of the stalks with a particle size of 20-80 meshes is composed of 35.6% cellulose, 21.6% hemicellulose and 18.1% lignin. Weigh 1000g of 20-80 mesh straw, add 10L formic acid (88%) and 100mL hydrochloric acid (37%) into the pretreatment bottle, start the constant temperature water bath, keep the reaction temperature constant at 65°C, the oscillation speed at 150rpm, and treat at normal pressure 3h, the sample bottle was taken out, placed in a low-temperature water bath, and the reaction slurry was subjected to solid-liquid separation (vortex centrifugation or suction filtration), wherein, the solid components were washed with water and then dried to obtain a total of 431g of materials, including 75.1% cellulose, The retention rate reaches 91%. Under the action of cellulase (30FPU / g glycoside), the material is hydrolyzed for 24h in pH4.8 citric acid buffer solution at 50°C, and its hydrolyzate is measured by HPLC (as shown in F...

Embodiment 2

[0032] The corn cob is crushed, wherein the core material with a particle diameter of 20-80 meshes is composed of 35.9% cellulose, 35.2% hemicellulose and 18.1% lignin. Weigh 100g of 20-80 mesh straw, add 1L of formic acid (88%) and 5mL of hydrochloric acid (37%) into the pretreatment bottle, start the constant temperature water bath, keep the reaction temperature constant at 55°C, the oscillation speed at 150rpm, and treat at normal pressure 3h, the sample bottle was taken out, placed in a low-temperature water bath, and the reaction slurry was subjected to solid-liquid separation (vortex centrifugation or suction filtration), wherein, the solid component was washed with water and then dried to obtain a total of 45.8g of material, which contained cellulose 68.5 %, the retention rate reaches 87%. Under the action of cellulase (30FPU / g glycoside), the material is hydrolyzed in pH4.8 citric acid buffer solution at 50°C for 24 hours, and the cellulose conversion rate can reach 72%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com