On-line testing method for aluminum cell anodic current distribution and monitoring device

An anode current and aluminum electrolytic cell technology, applied in the field of online detection of anode current distribution in aluminum electrolytic cells, can solve problems affecting the accuracy of anode current, reducing the reliability of analysis data, and affecting the precise control of electrolytic aluminum, so as to prevent anode shedding faults , Furnace specification, the effect of reducing anode consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

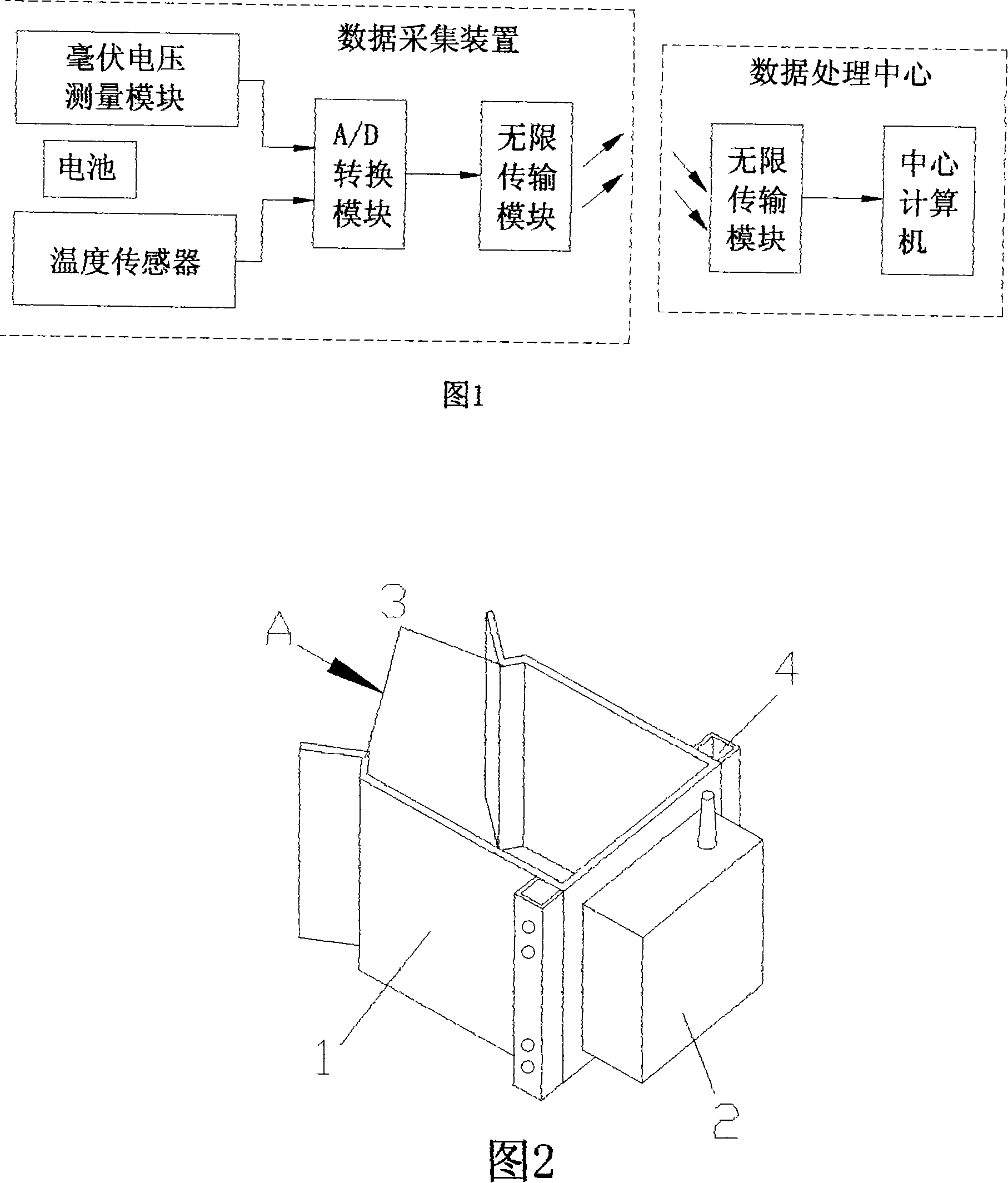

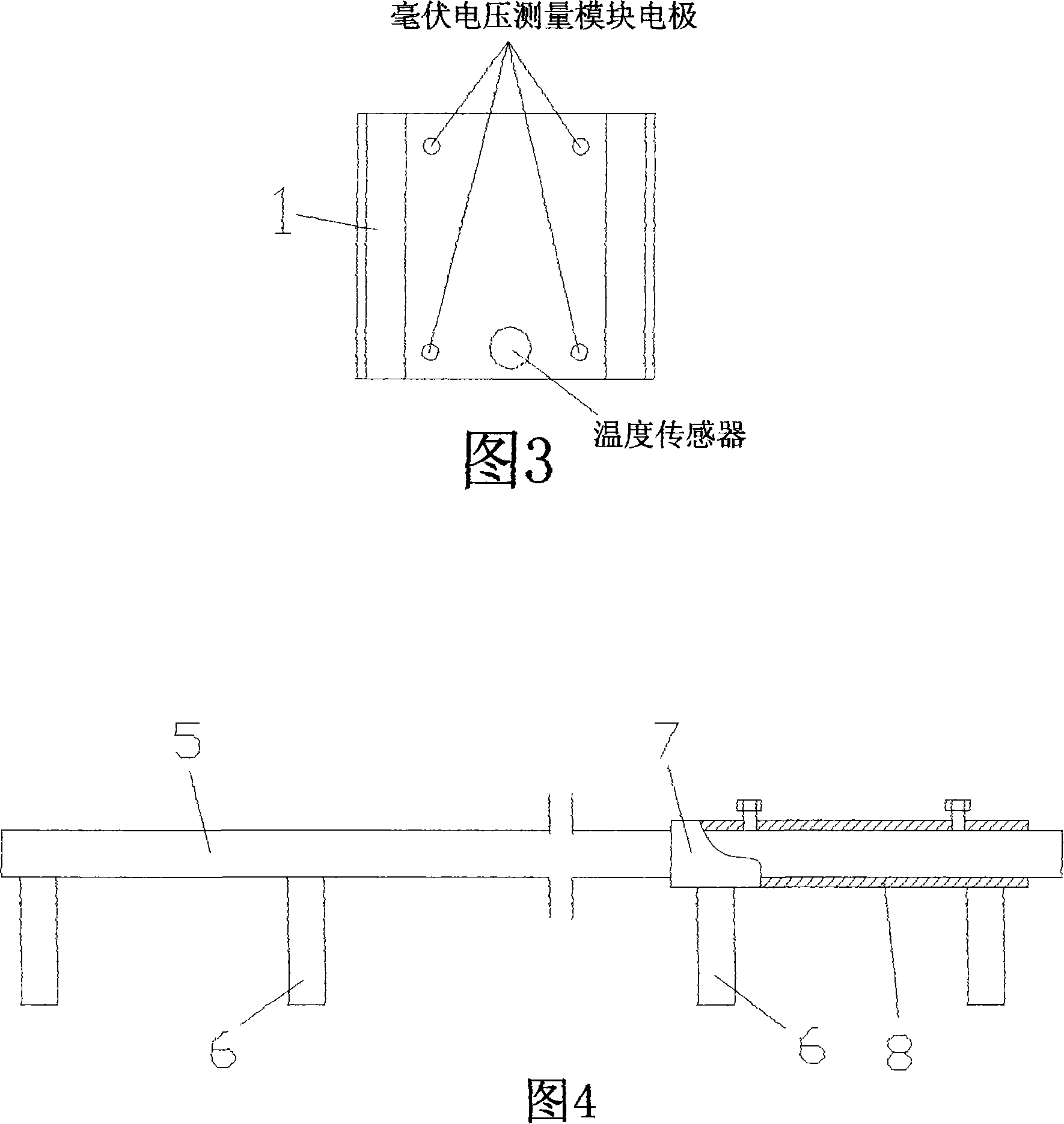

[0016] As shown in Fig. 1, Fig. 2 and Fig. 3, the online monitoring method system of the anode current distribution of the aluminum electrolytic cell of the present invention includes a voltage data acquisition device and a data processing center. The data acquisition device includes a measurement unit and a fixture. The measurement unit is composed of a millivolt voltage measurement module, a temperature sensor, an A / D conversion module, a wireless transmission module, and a battery power supply. The same measurement module and sensor in the millivolt meter, the voltage data measured by the millivolt voltage measurement module and the temperature data measured by the temperature sensor are input to the A / D conversion module, and the temperature data is used in the A / D conversion module to correct the voltage data. And the corrected voltage data is converted into current data, and then the obtained current data is converted into a digital signal and transmitted to the wireless ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com