Clamp device with adjustable manipulator angle

A technology of angle adjustment and gripper, which is applied in the direction of chucks, manipulators, manufacturing tools, etc., can solve the problems of easily damaged optical devices and achieve the effect of protecting from damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

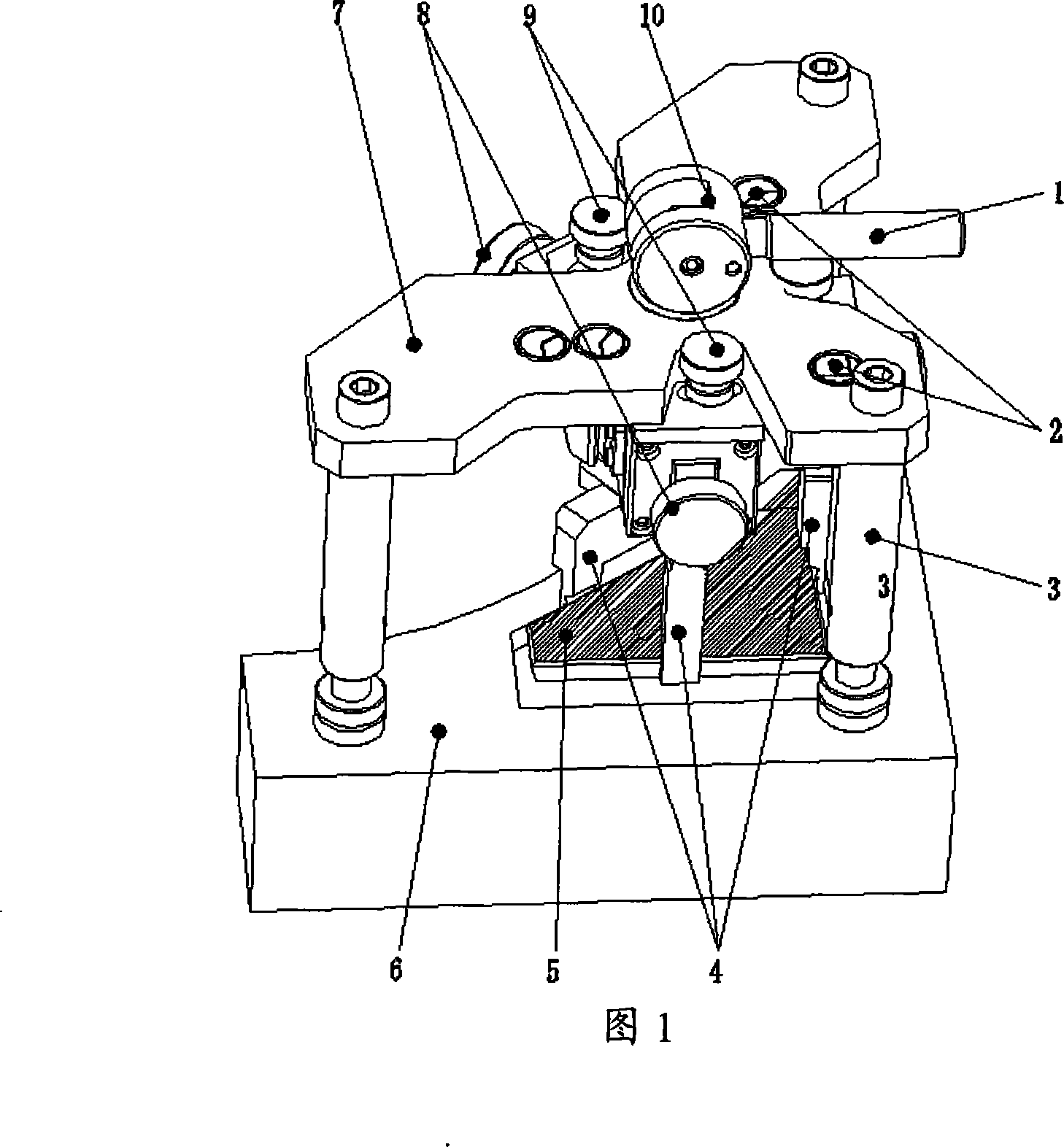

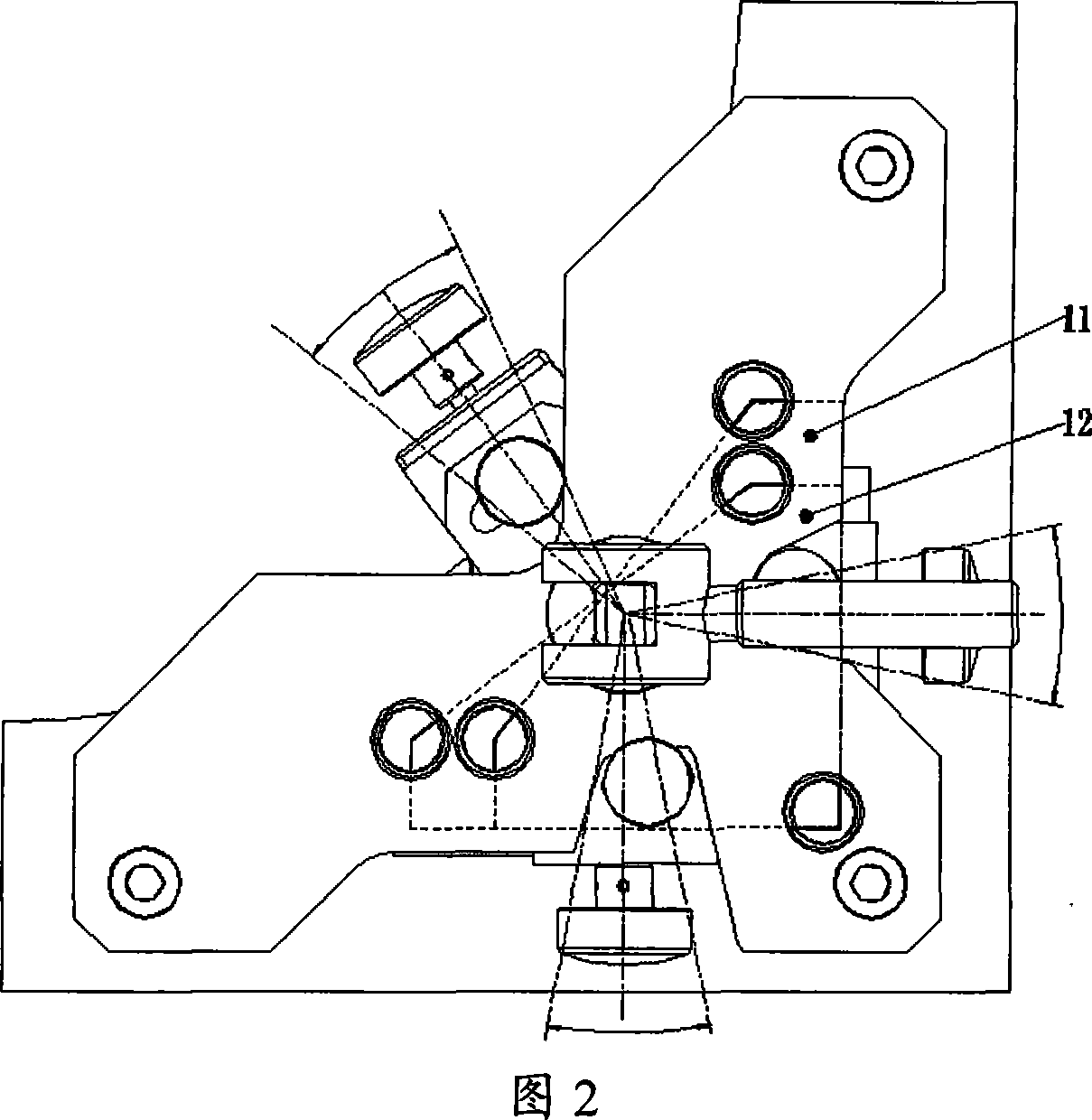

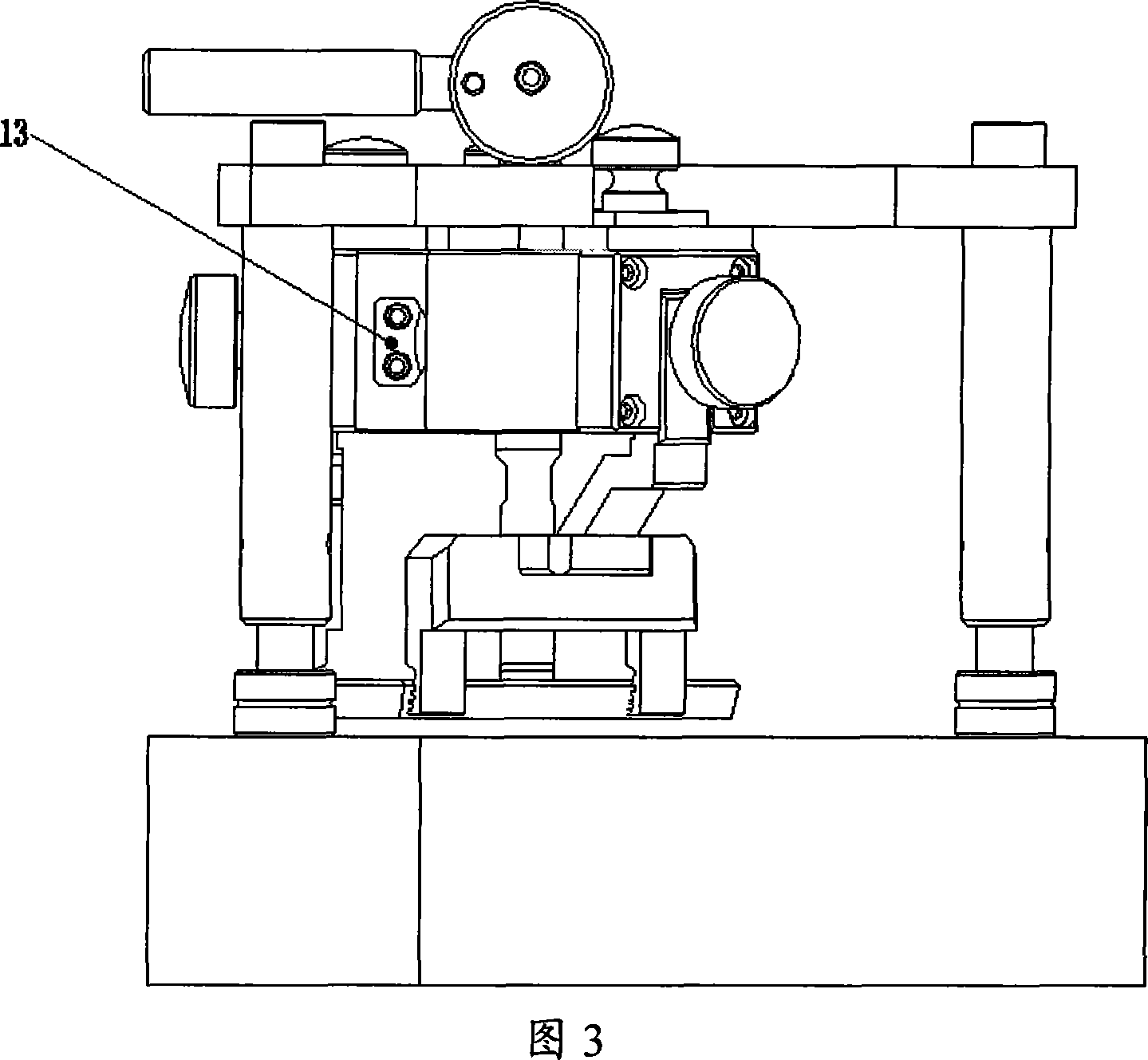

[0041] The clamping device with adjustable gripper angle provided by the present invention will be described in detail below in conjunction with a specific embodiment. As shown in FIG. Standing legs 3 of the device 5, a gripper 4 for grabbing the optics 5, an eccentric lifting mechanism for raising or lowering the gripper 4, a locking mechanism for fixing the gripper 4 and the optics 5 together and An angle adjustment mechanism for adjusting the parallelism between the handle 4 and the side of the optical device 5, wherein the standing leg 3, the handle 4, the eccentric lifting mechanism and the angle lifting mechanism are all fixed on the base plate 7, and the handle 4 is connected with the eccentric lifting mechanism , the angle adjustment mechanism and the locking mechanism are installed on the gripper 4, five pre-alignment mark holes 2 are arranged on the substrate 7, and alignment marks of transparent organic glass are pasted on the mark holes.

[0042] There are three st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com