Outer diameter edge circle measurer

A measuring instrument and platform technology, applied in the direction of measuring devices, mechanical measuring devices, mechanical counters/curvature measurement, etc., can solve the problems of easy error, long measurement time, uneconomical, etc., to achieve simple and convenient operation, improve work efficiency and Effects of labor productivity and reduction of measurement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

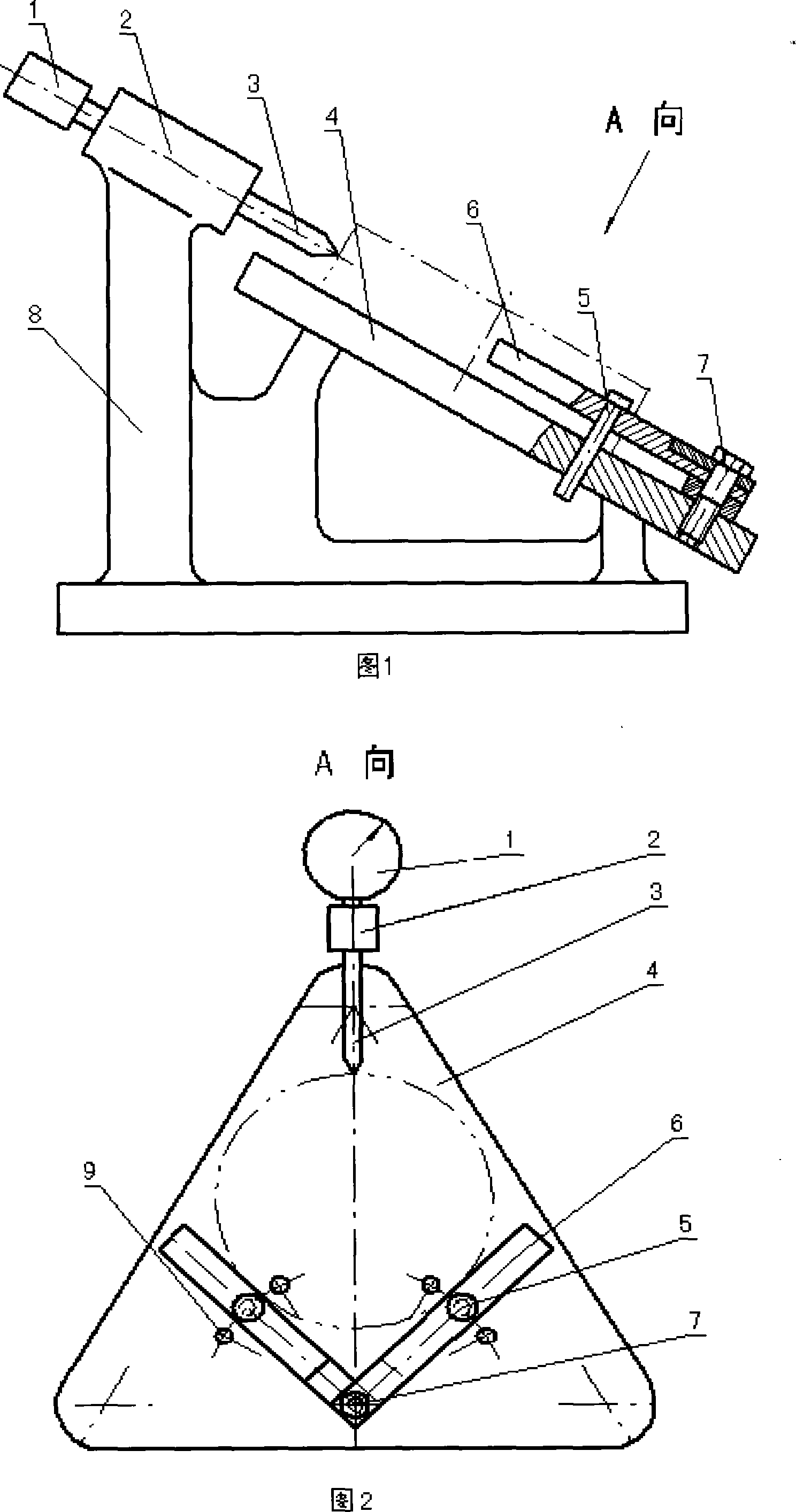

[0009] The present invention will be further described below in conjunction with drawings and embodiments.

[0010] In the embodiment of Fig. 1 and Fig. 2, the dial 1, the table frame 2, the meter head 3, the base 8 and the platform 4 all utilize the original parts of the original outer diameter and edge circle measuring instrument, on the center line of the bottom edge of the platform 4 There is an M8 screw hole drilled at 15mm-30mm. The scissor frame 6 of the variable-angle V-shaped device is made of medium carbon steel. The scissor frame 6 is 100mm-140mm long, 8mm-12mm high, 12mm-18mm wide, and One side of the scissor frame is made into a knife-edge shape as a support for the circular workpiece, and is on the same plane as the meter head 3. The installation hole diameter of one end of the scissor frame 6 is 10mm, and the two scissor frame frames are connected by a bolt 7 with a spring. 6 is fixed in the screw hole at the lower part of the platform 4 to form a V shape, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com