Sample warper and method for forming a sample warp

A technology of jacquard chains and warping machines, applied in warping machines, transportation and packaging, pattern design devices, etc., can solve problems such as high cost, and achieve the effect of simplified adjustment and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

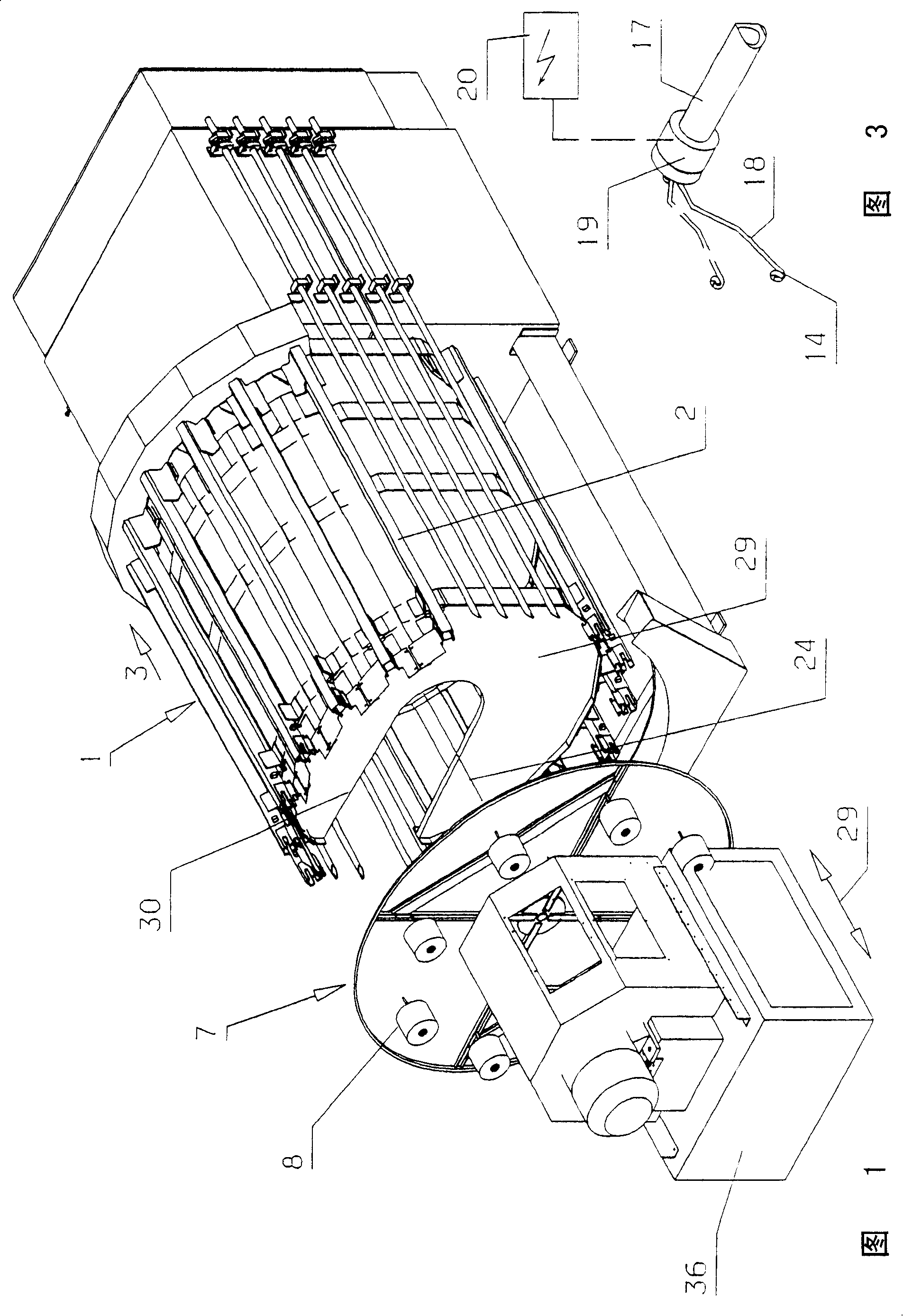

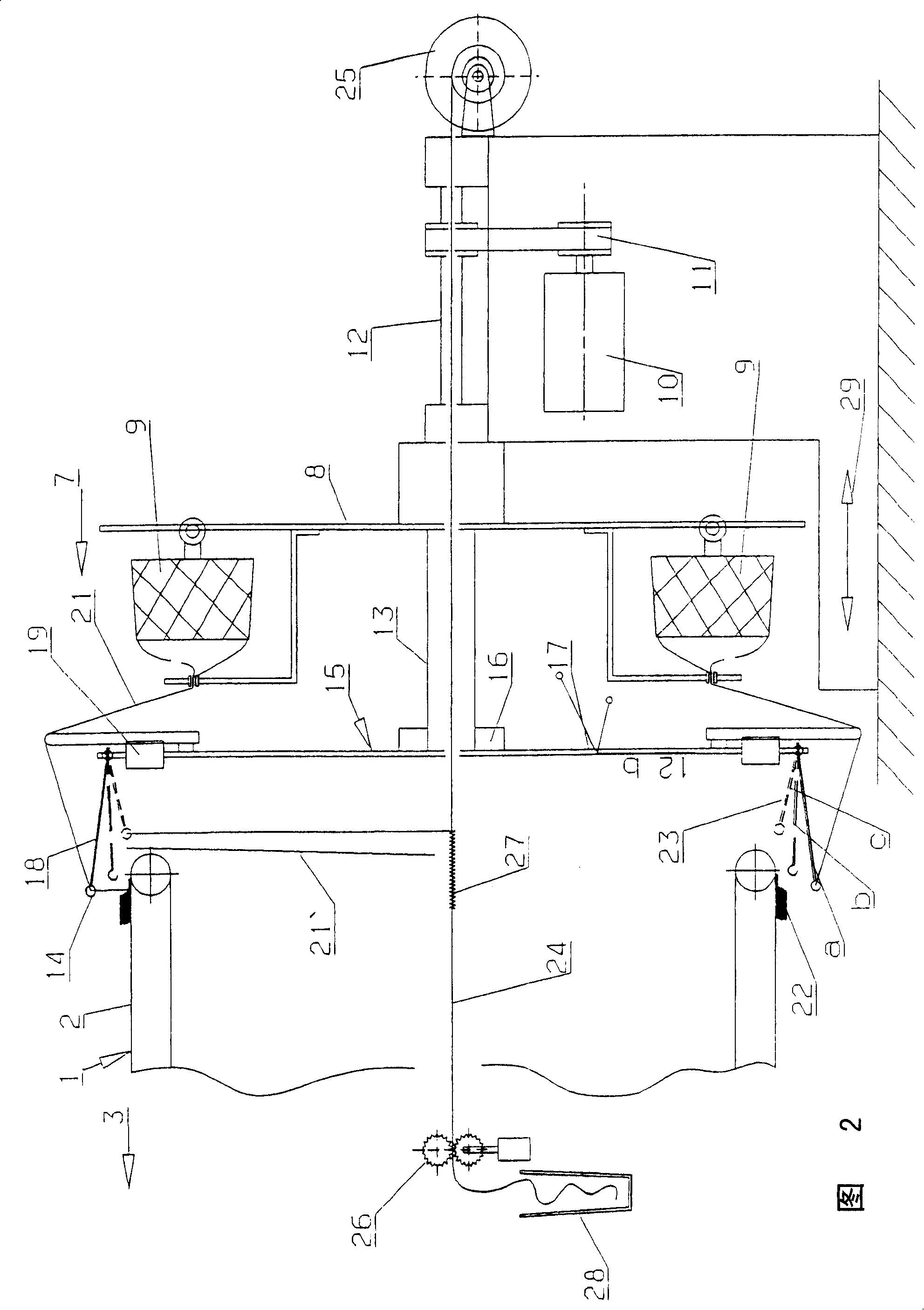

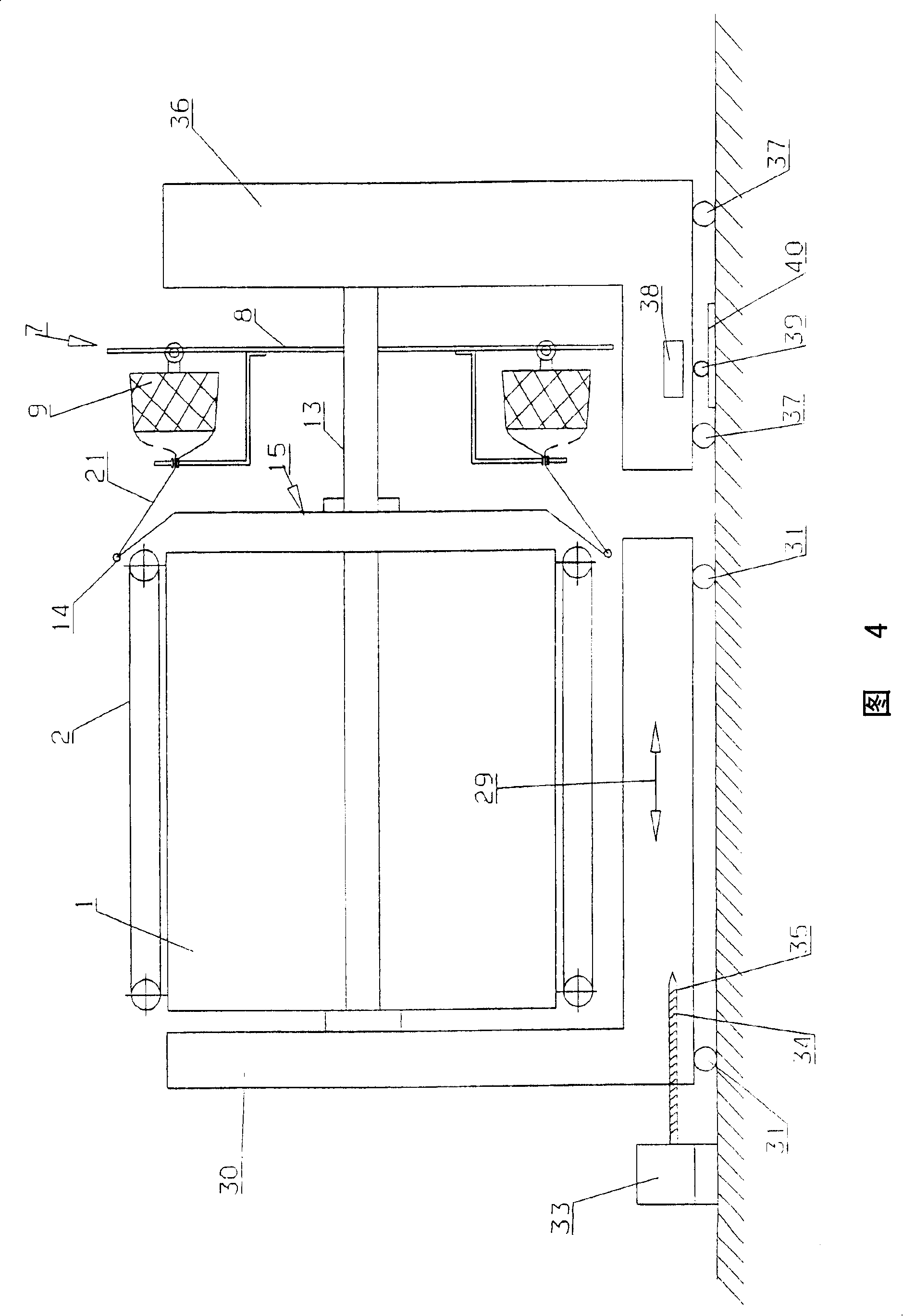

[0029] The Jacquard chain warper has a warping cylinder 1 on the circumference of which a plurality of conveyor belts 2 are arranged, and if the Jacquard chain is warped, these conveyor belts 2 run parallel to the warping The axis of the drum moves in the direction of arrow 3 . Parting rods, not shown in detail, are used for skew winding, sizing or other functions. The outer branches of the conveyor belt 2 each form a conveying surface.

[0030] The rotating creel 7 has a rotor 8 on which a plurality of bobbins 9 is fastened. The rotor 8 can be driven by an electric motor 10 via a belt drive 11 and a hollow shaft 12 .

[0031]A further hollow shaft 13 ( FIG. 2 ) rotates synchronously with the hollow shaft 12 , on which a thread guide support 15 with a thread guide 14 is fastened in a rotationally fixed manner. The thread guide support 15 has radial arms 17 held in a hub 16 . On the outer end of the radial arm 17 is articulated a lever 18 which can be pivoted by means of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com