High expansion foam fire-extinguishing system

A technology of foam fire extinguishing and foam fire extinguishing agent, which is applied in fire rescue and other directions, can solve the problem of high cost, and achieve the effects of easy formation of bubble film, reliable fire extinguishing, and prevention of reduction in foaming rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

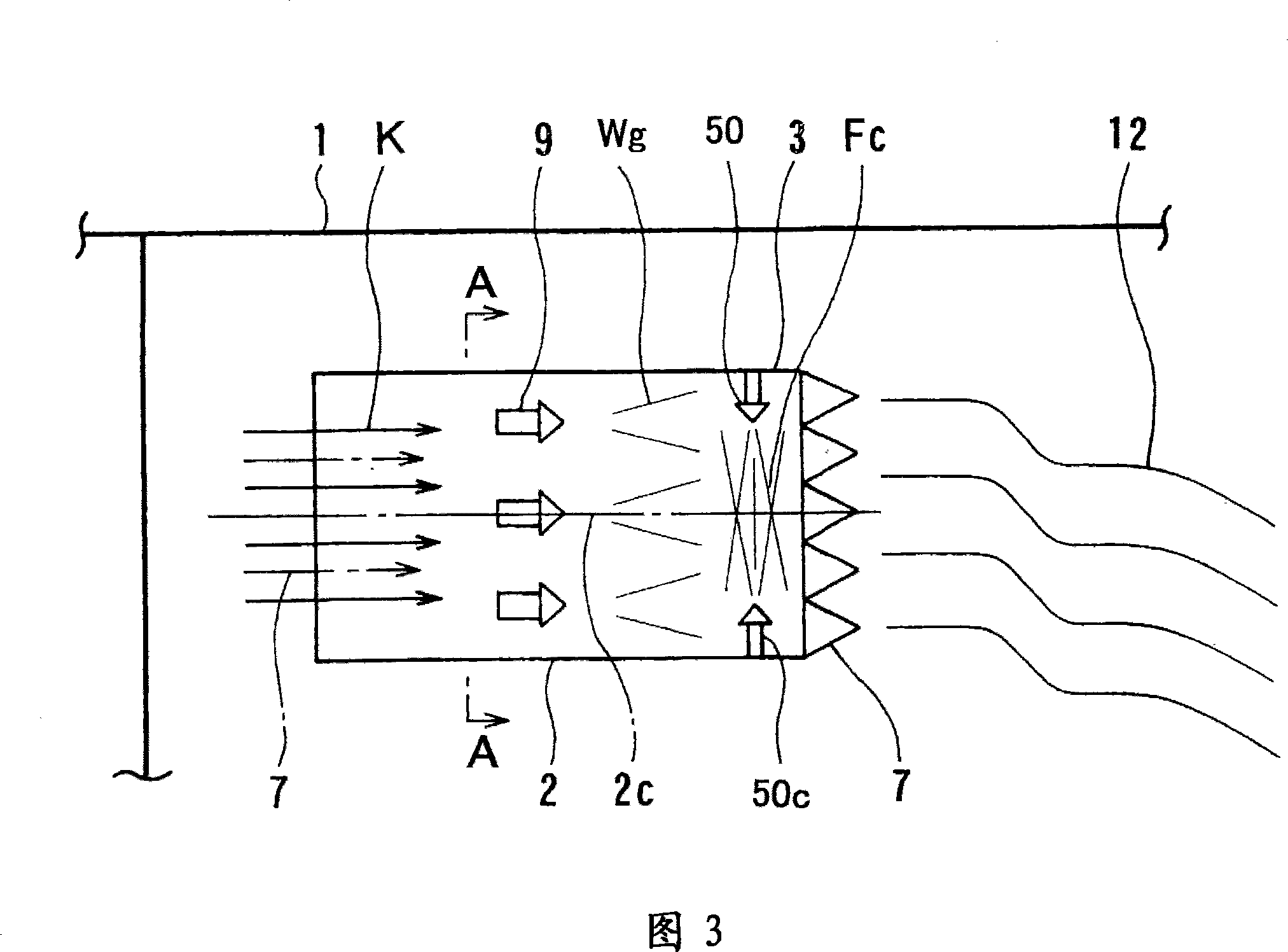

[0061] Below at first referring to Fig. 1, Fig. 2 the embodiment of the first invention is described.

[0062] A high-expansion foam fire extinguishing device is provided in a room (chamber) 1 as a foam discharge area. The fire extinguishing equipment is a foaming machine provided with a flow channel tube 2, and its foaming rate is set at 500 times, for example. In this flow path tube 2 is provided a foaming portion 3 (foaming portion 3 ) that sucks air in the discharge area 1 by driving the spray nozzle 9 to generate foam in the foam solution.

[0063] A net 7 for foaming (net 7 for generating foam) is opened in the foaming part 3 at the front end of the flow channel tube 2. In addition, a plurality of nets 7 facing the foaming at intervals are provided inside it. Spray nozzle 9. Such a foaming machine has a structure in which a foam solution and air are supplied in accordance with the foaming rate. The spray nozzle 9 is connected to a water supply source (not shown) throu...

no. 1 example

[0083] In the high-expansion foam fire extinguishing equipment of the above-mentioned embodiment, the mixing ratio of the above-mentioned Megaform F623T (registered trademark) is made larger than the above-mentioned standard mixing ratio. In order to adjust the mixing ratio, the fluorine-based surfactant is relatively It is an experiment in which the mixing ratio of the foaming water solution reaches the design foaming rate concentration and makes it foam. The experimental results are shown in Table 1. In this Table 1, the foam fire extinguishing agent (%) column represents the adjusted mixing ratio, the fluorosurfactant concentration (%) column represents the design foaming rate concentration, and the foaming rate column represents the actual foaming rate. bubble rate.

[0084] As can be seen from Table 1, for example, when the mixing ratio is adjusted to 4.0%, the design expansion ratio concentration is 0.4%, the expansion ratio is 240 times, and the desired expansion ratio ...

no. 2 example

[0094] In the second experimental example, for the foam fire extinguishing agent, instead of the aqueous film-forming foam fire extinguishing agent, a synthetic surfactant fire extinguishing agent is used, and the foaming experiment is carried out in the same way as above, and its experimental conditions are the same as those of the first experimental example above. same.

[0095] As the above-mentioned synthetic surfactant fire extinguishing agent, Snow-lap H (registered trademark) mainly composed of a hydrocarbon-based surfactant was used, and the standard mixing ratio of this fire extinguishing agent was 3%. The experimental results are shown in Table 2. In this Table 2, the foam fire extinguishing agent (%) column represents the adjusted mixing ratio, the hydrocarbon-based surfactant concentration (%) column represents the design foaming rate concentration, and the foaming rate column represents the actual foaming rate. bubble rate.

[0096] As can be seen from Table 2, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com