Controller

A technology for control devices and control valves, applied in transportation and packaging, load suspension components, machines/engines, etc., can solve problems such as vacuum grippers passing by the workpiece or passing through the workpiece, damaging the sealing lip, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

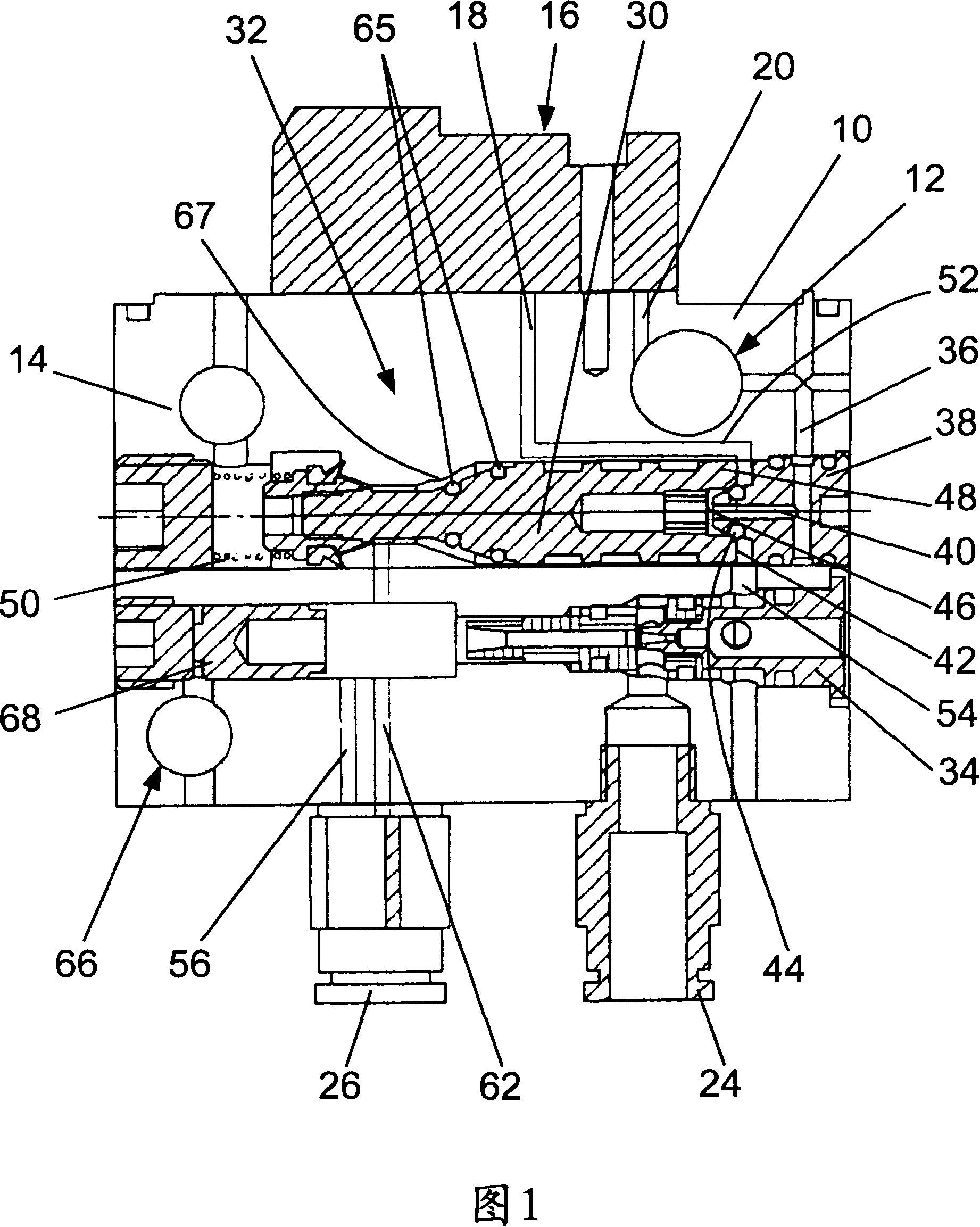

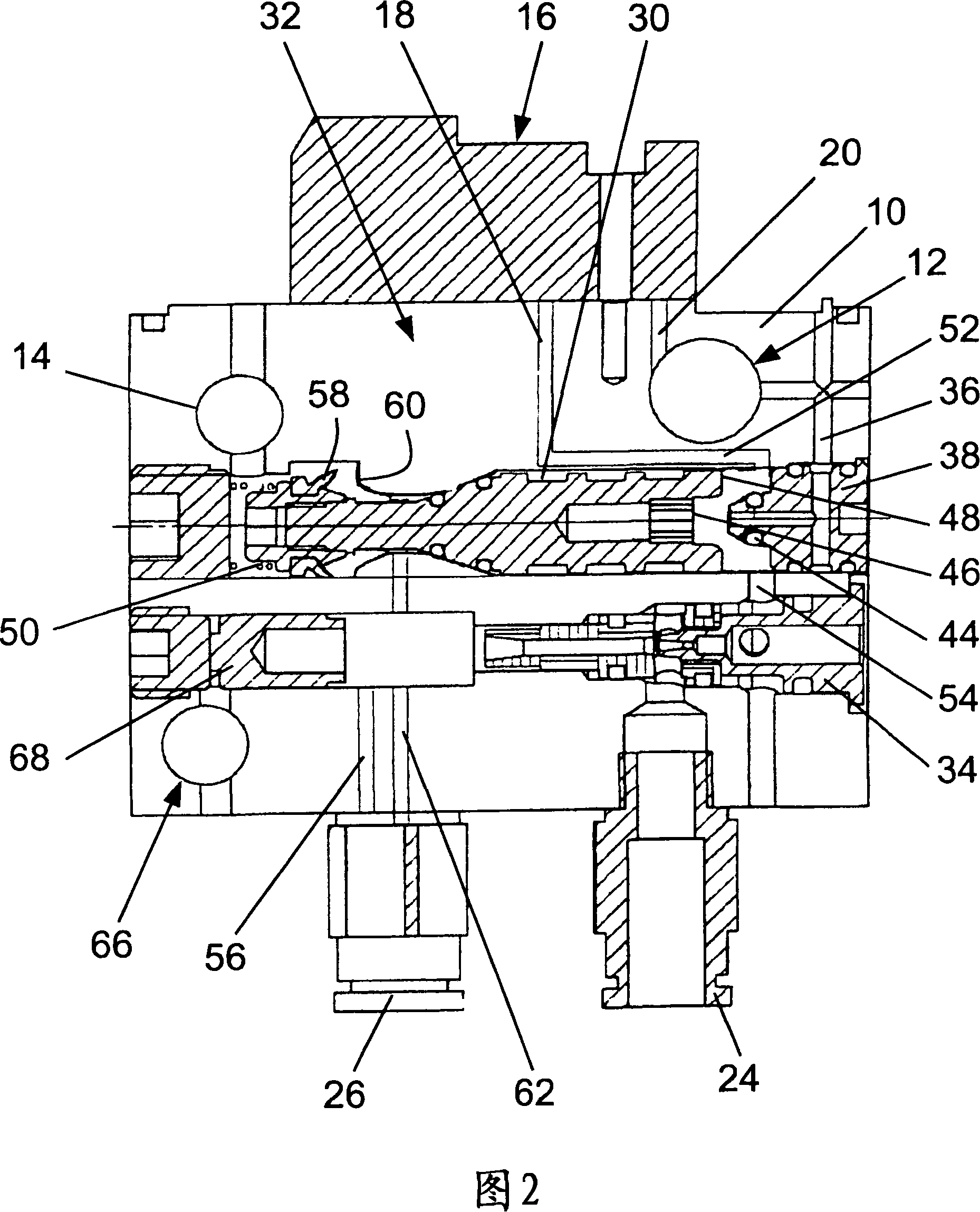

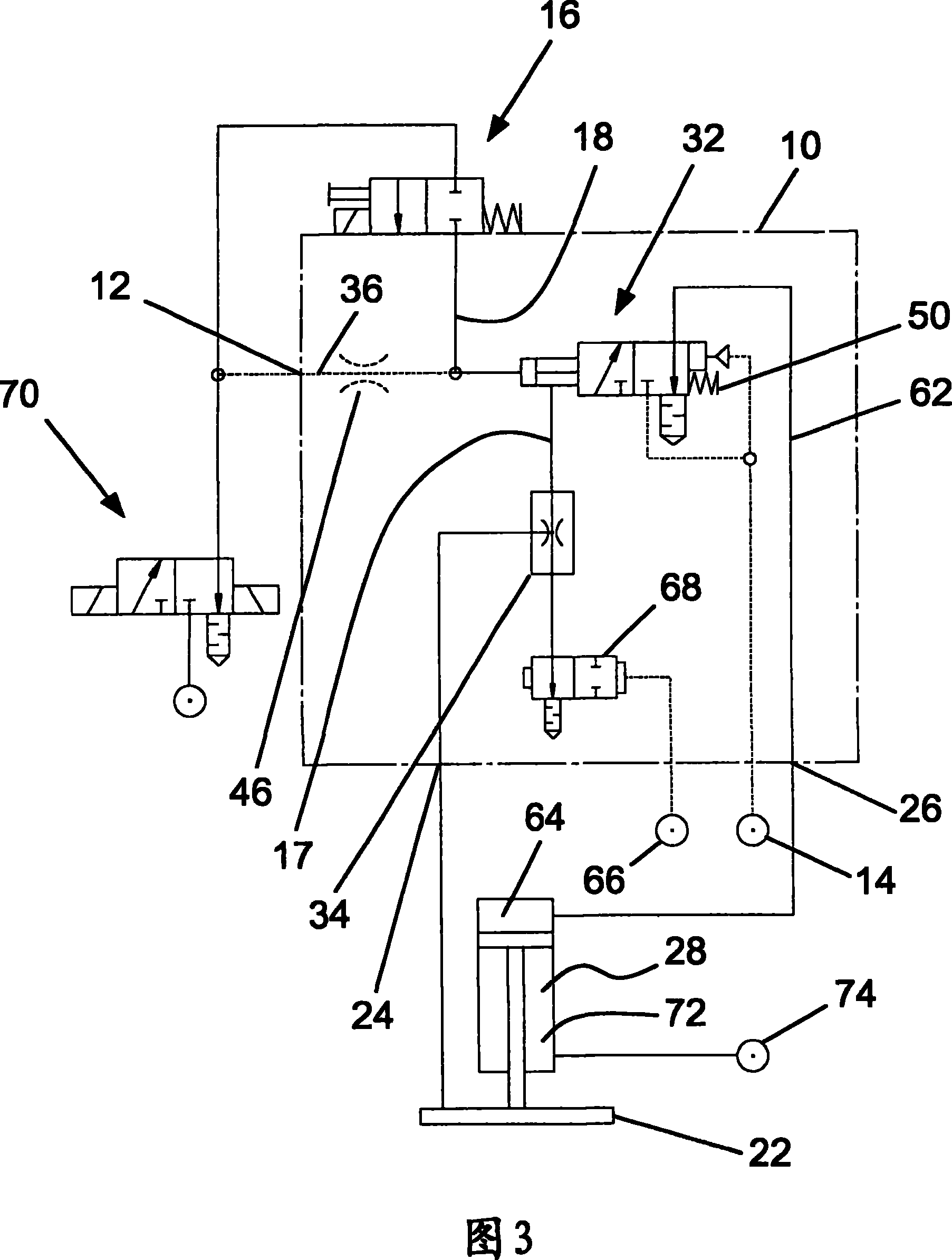

[0027] exist figure 1 and 2 10 shows a valve block, which is constructed as a solid component. The valve block 10 has an inlet 12 for working compressed air and an inlet 14 for working fluid, wherein the inlet 12 is designed as a transverse bore, and the inlet 14 is likewise designed as a transverse bore. These transverse holes have the advantage that multiple valve groups 10 can be figure 1They are arranged consecutively in the viewing direction, so that the inlets 12 and 14 are each aligned with each other, so that all valve groups 10 can be supplied with working compressed air and working fluid together. Furthermore, it can be seen that a pilot valve 16 is mounted on the valve block 10 , with which an input 18 for controlling compressed air is opened and closed. These parts all have the same width (dimension seen in the viewing direction).

[0028] The input 18 has a connection 20 to the input 12 so that the control compressed air can be branched off from the working co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com