Sub-health running status recognition method of electrical device

A technology of operating status and identification method, applied in the direction of measuring device, measuring electricity, fault location, etc., can solve the problems of burning components, equipment, electrical device loss, manpower and material resources, etc., to achieve high reliability and reduce losses , cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

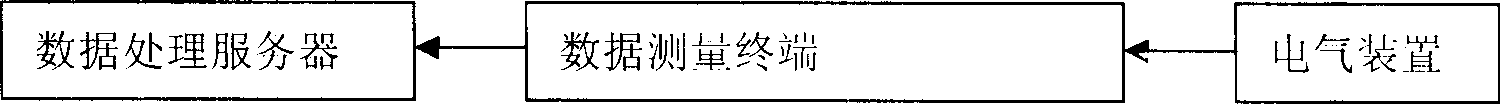

Embodiment 1

[0025] The method of identifying the "sub-healthy" operating status of electrical devices uses the parameter measurement of the 27n80 field effect tube to illustrate the working principle. The microprocessor adopts PIC18F2550, supports multi-channel ten-digit precision A / D conversion, and integrates USB2 .0 communication module, M is Hall DC transformer, used to measure the current flowing through the two pins when the field effect tube is working normally, so as to obtain the resistance value of the PN junction, which is measured by the voltage drop between the field effect tube PN junction The change can determine whether the field effect tube is working normally, whether it is in the "pressure healthy" working state, that is, the fault critical state. There are three A / D monitoring points in the circuit, which are used to measure the gate conduction voltage and mutual inductance of the field effect tube. The sensor induces voltage and PN junction voltage drop.

[0026] Working...

Embodiment 2

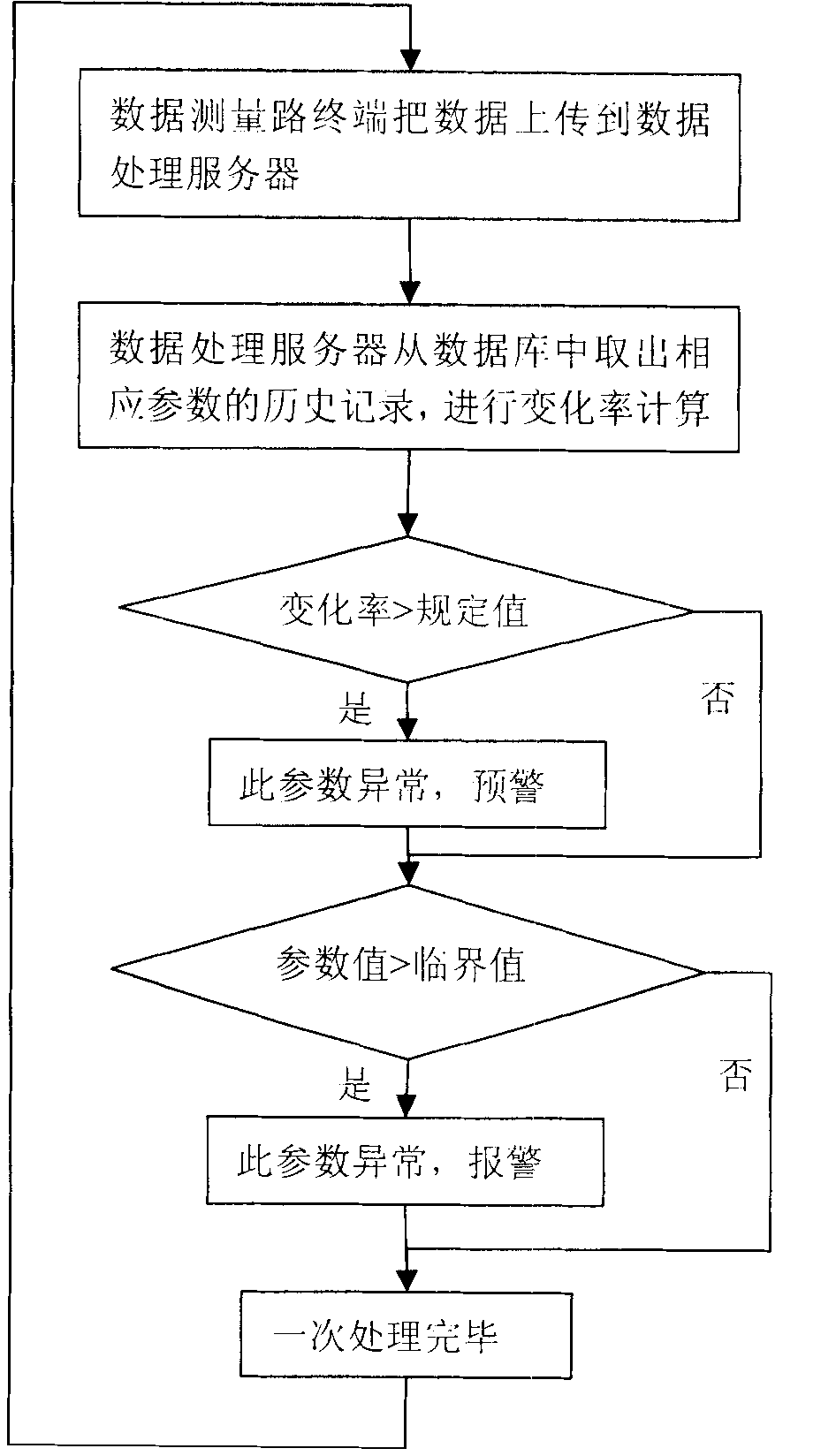

[0032] The method for identifying the "sub-healthy" operating state of an electrical device described in Example 1, is based on the attached figure 1 , The data processing server is embedded in the device, and a cost-effective embedded system is used as the data processing server. The collected signals are transmitted to the data processing server through various methods. The server calculates the parameter change rate. If it exceeds the standard range, Pre-alarm in time, because there are fewer equipment, a cost-effective embedded system can meet the real-time requirements of data storage and computing.

Embodiment 3

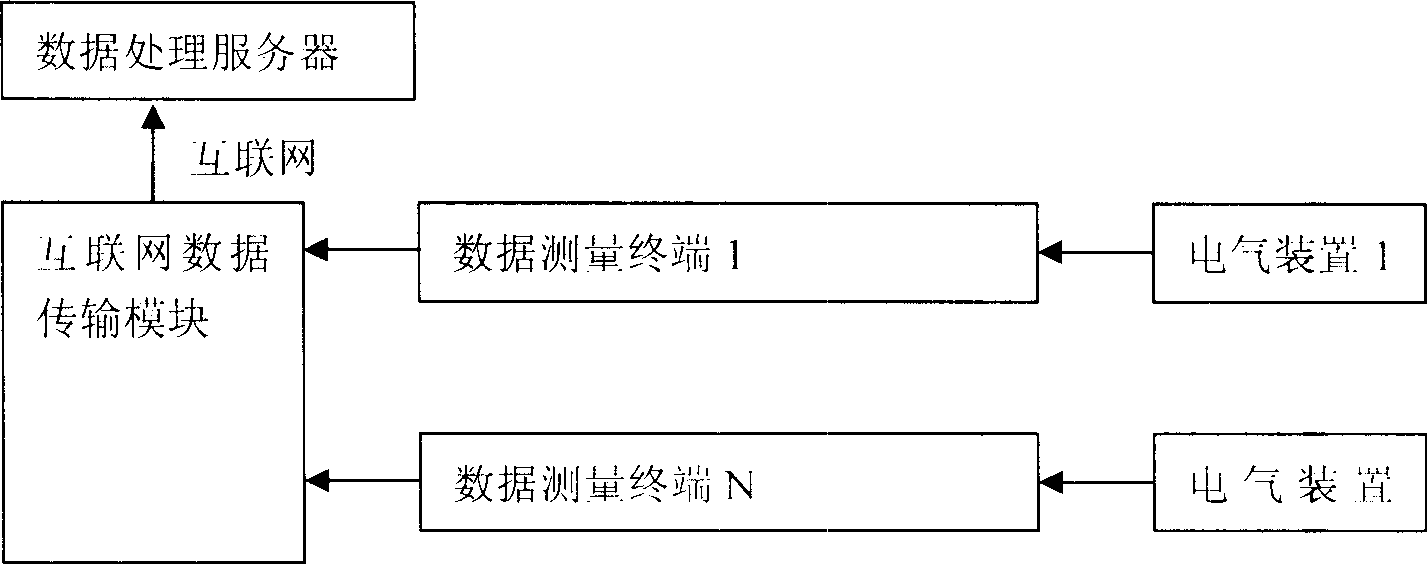

[0034] The method for identifying the "sub-healthy" operating state of an electrical device described in embodiment 1 or 2, as attached figure 2 , The data processing server is remote, for example, the data processing server is located at a node on the Internet, and this server has high performance, can withstand a large amount of data storage, calculation work, this method is suitable for electrical device manufacturers, with a wide range of Customer groups and areas far away from the after-sales service can achieve unified detection and unified management of products bought all over the world in this way, so that a data measurement terminal and an Internet data transmission module can be added to the electrical device. The Internet data transmission module uploads the results of multiple data measurement terminals to the manufacturer’s data processing server for unified storage and management in batches and classifications. The data processing server regularly classifies and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com