LCD display module

A liquid crystal display module and liquid crystal display panel technology, which is applied in the direction of static indicators, printed circuit components, etc., can solve the problems of difficult disassembly, difficult assembly, and consuming assembly man-hours, so as to save production man-hours and labor costs, The effect of solving assembly and disassembly problems and simplifying assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

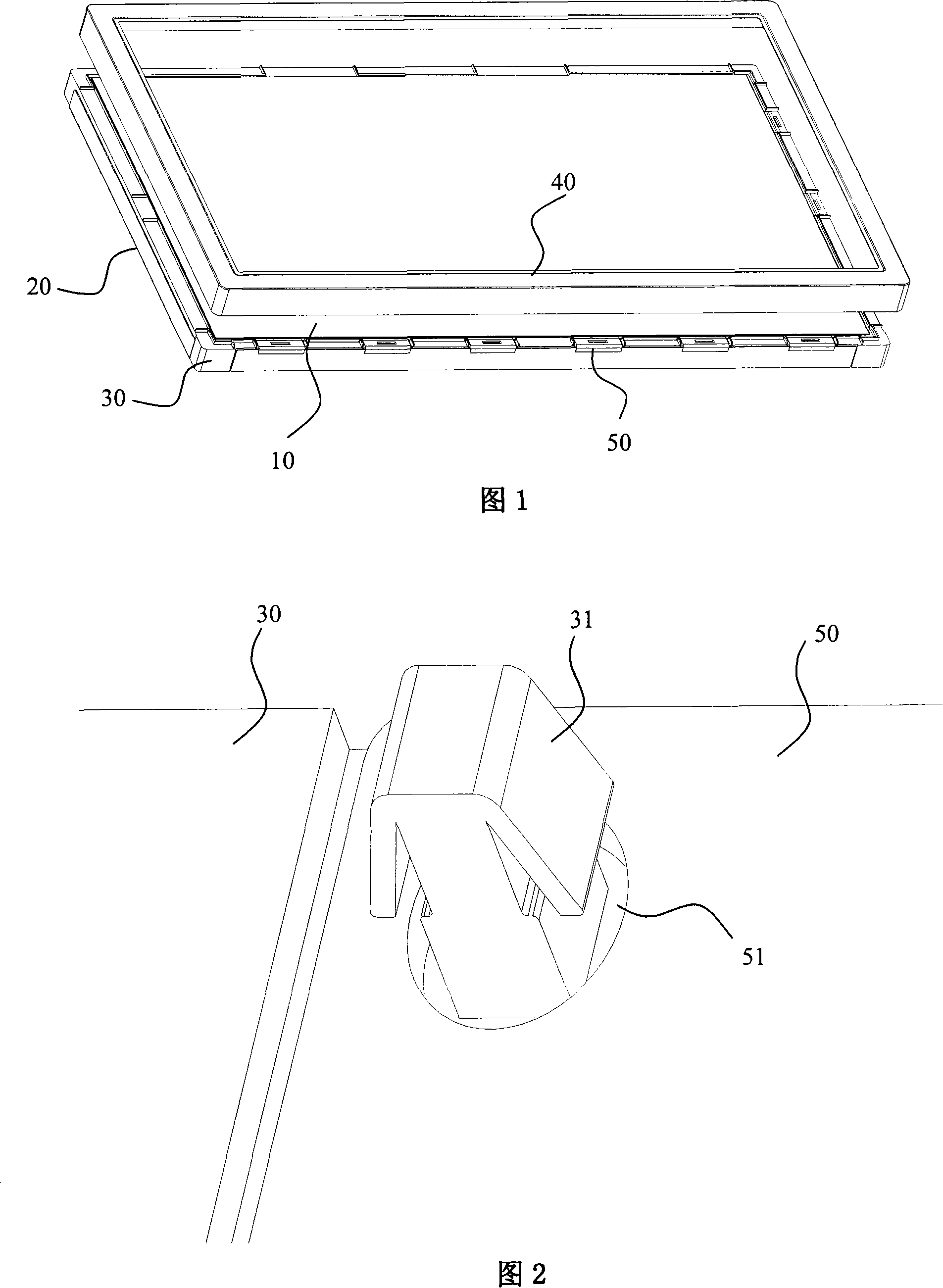

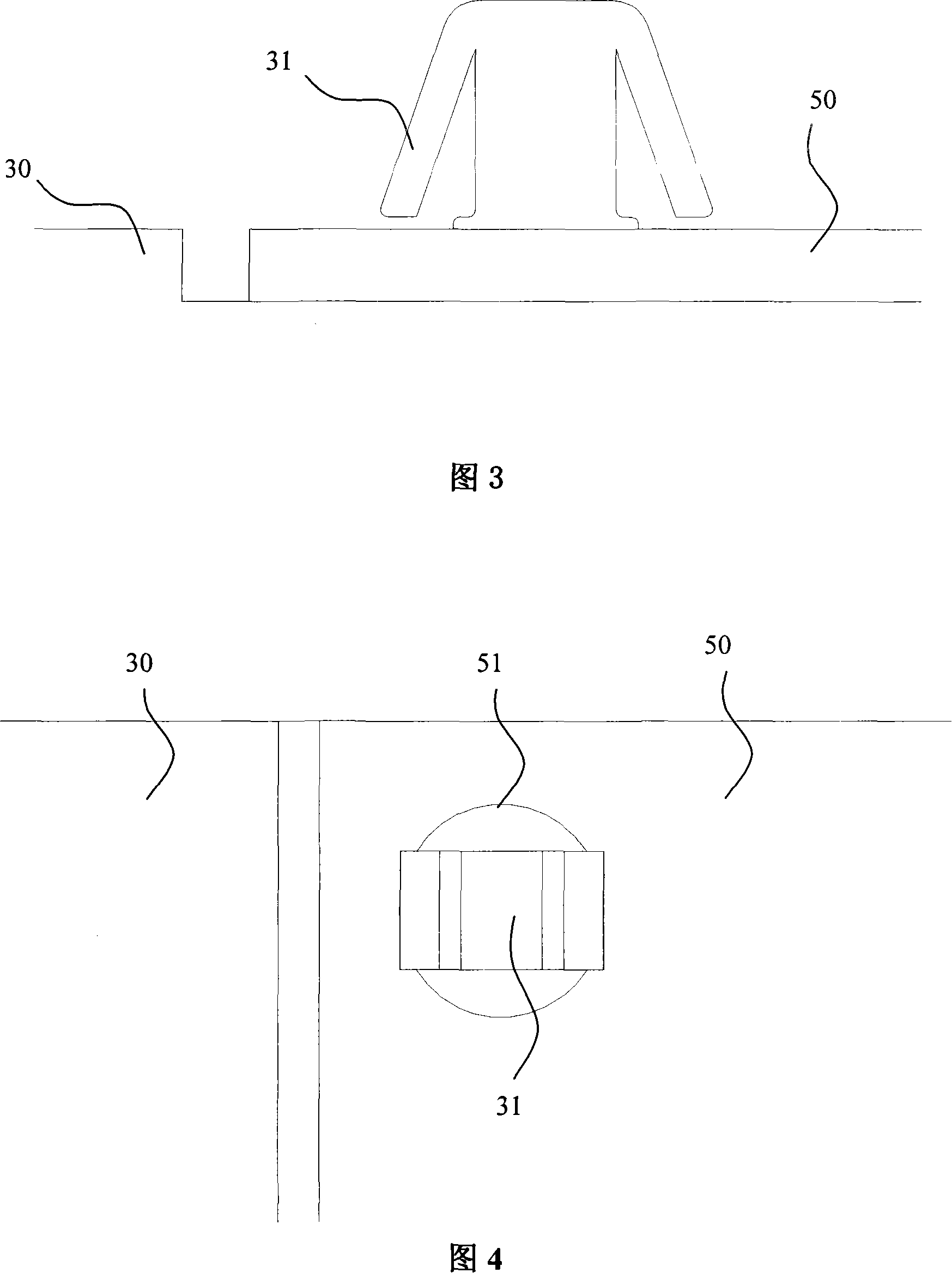

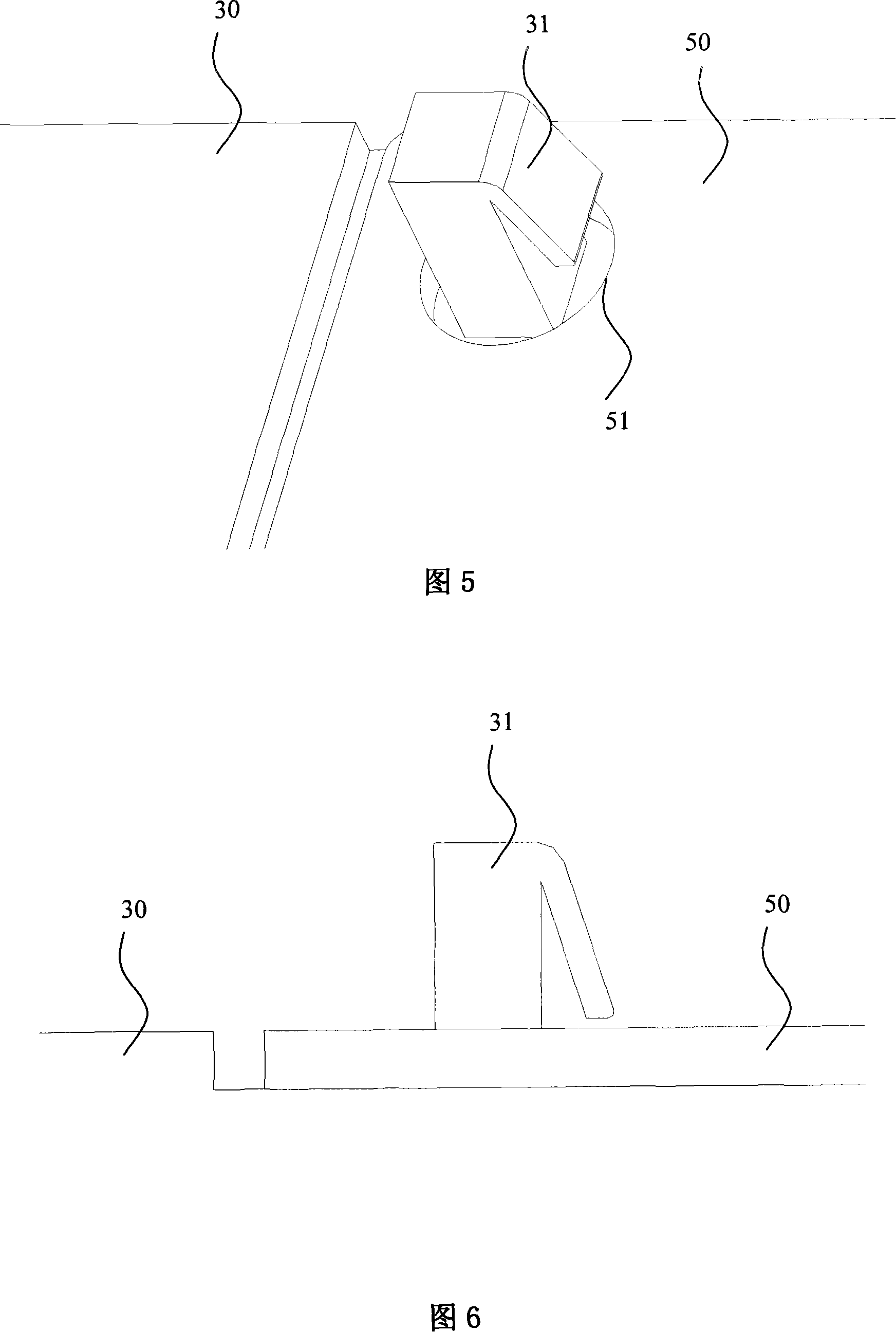

[0027] Referring to Fig. 2, Fig. 3 and Fig. 4, the liquid crystal display module of the present embodiment at least includes a liquid crystal display panel 10, a backplane 20, a first frame 30, a second frame 40 and a PCB board 50, and the first frame 30 is placed On the back plate 20, the second frame 40 covers the first frame 30, and the liquid crystal display panel 10 is accommodated in the first frame 30; the PCB board 50 is fixed on the first frame 30; The frame 30 is provided with a hook 31 , and the PCB 50 is provided with a hole 51 corresponding to the position of the hook 31 . In a preferred embodiment, the first frame 30 is a plastic frame, and the second frame 40 is a metal frame.

[0028] The liquid crystal display panel 10 includes a first substrate, a second substrate, and a liquid crystal layer filled between the first and second substrates (not shown in the figure); the first frame 30, the second frame 40 To position the liquid crystal display panel 10 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com