An inlet device for a fluid fed tangentially into an apparatus

A fluid and inlet technology, applied in the field of inlet devices, can solve the problems of energy consumption, suboptimal and disadvantageous, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

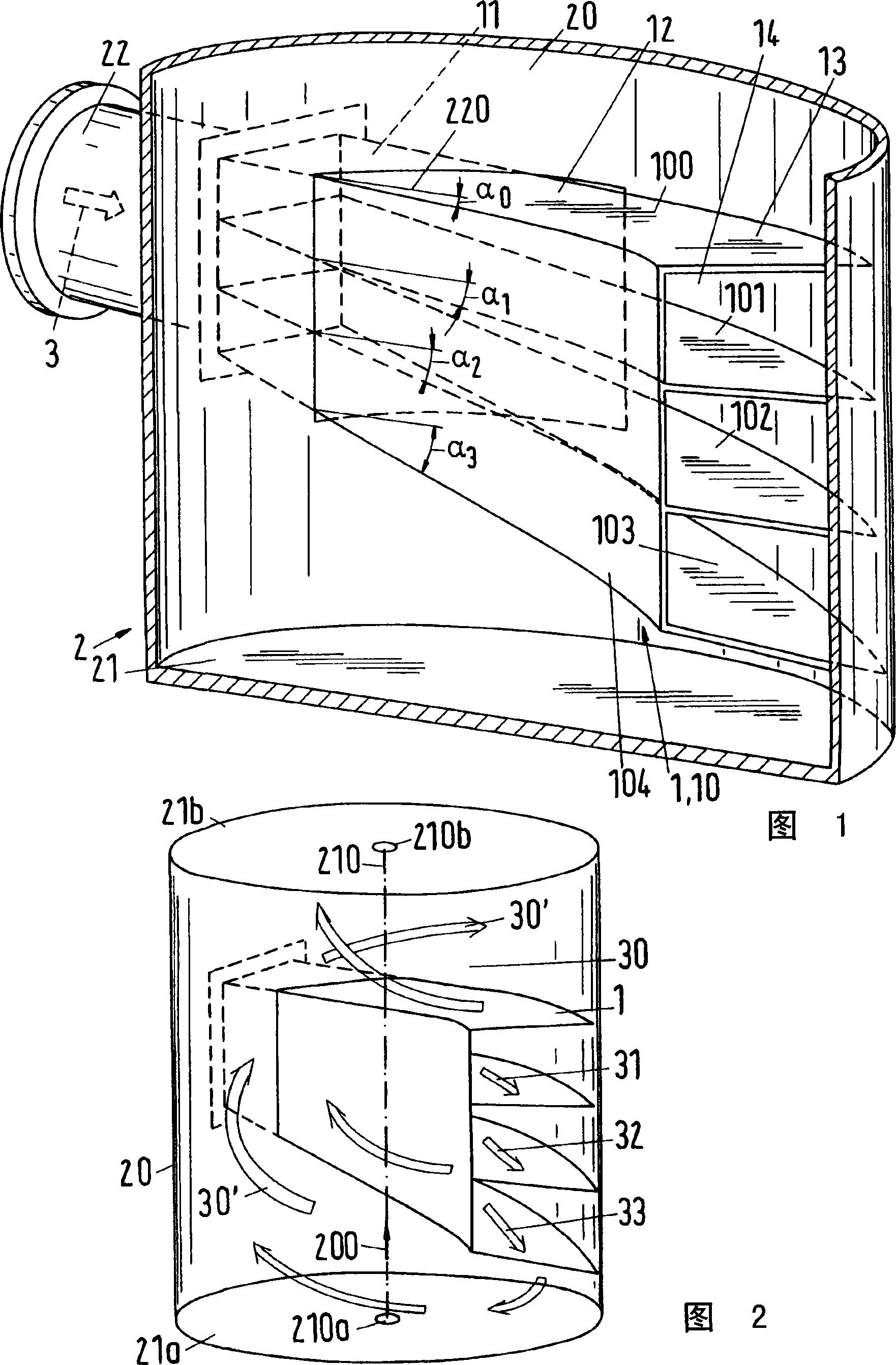

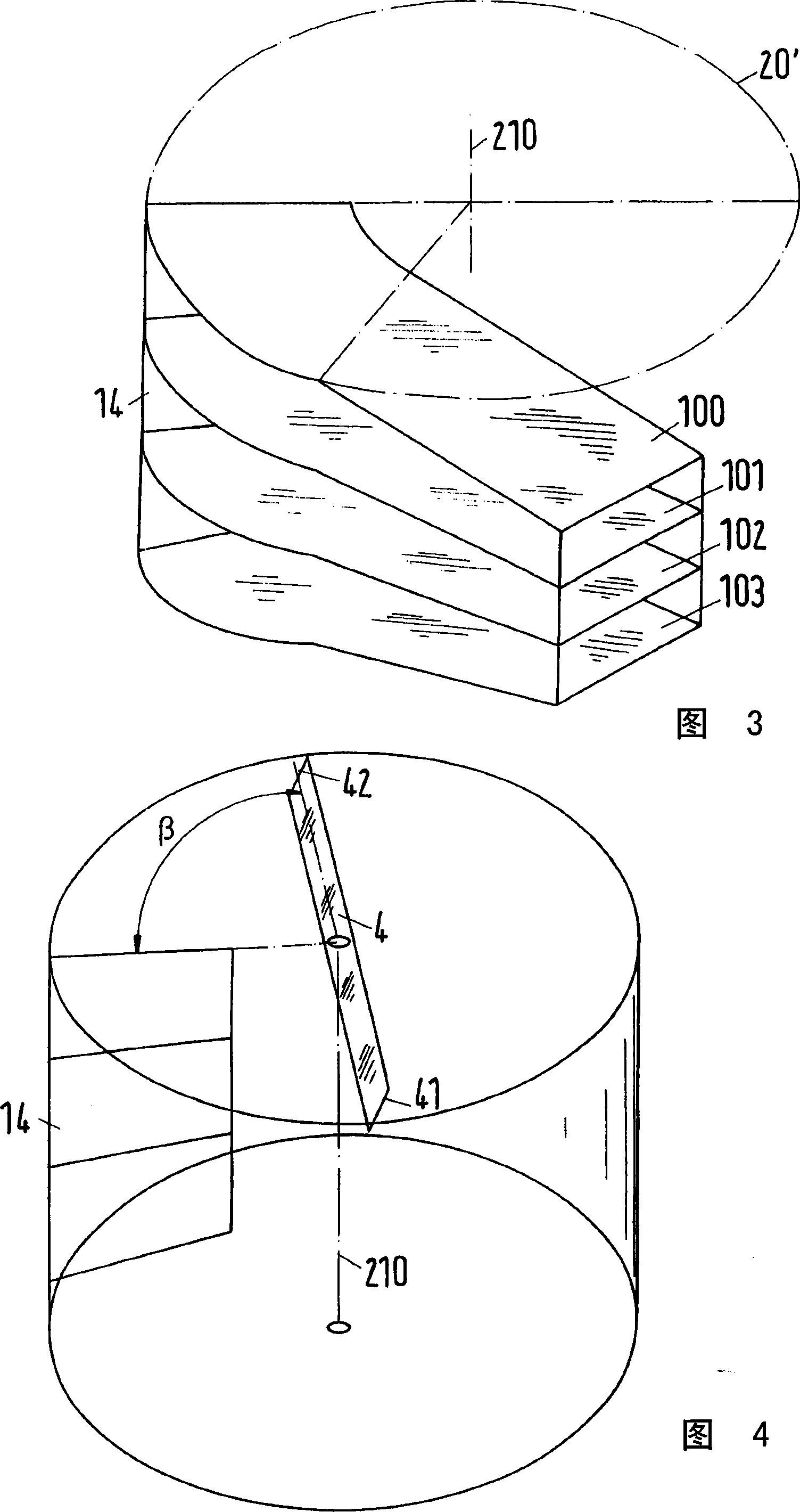

[0021] The fluid 3 flows tangentially into the device 2 , in particular a cartridge, through the inlet arrangement according to the invention as shown in FIGS. 1 and 2 . The sketch in Fig. 2 illustrates a portion of the interior space of the device 2, which is delimited by a perimeter 20, a lower cross-section 21a and an upper cross-section 21b. The center point 210a of the lower cross-section 21a (which corresponds to the base 21 in FIG. 1 ) is connected to the center point 210b of the upper cross-section 21b by a central axis 210 .

[0022] The fluid 3 first flows through the connecting socket 22 and then through the flared duct 10 on the periphery of the device 2 . In the connection socket 22, the cross-sectional surface changes from a circle to a rectangle. Fluid 3 leaves channel portion 10 through discharge region 13 and discharge surface 14 and enters vortex 30 in the direction indicated by arrow 30'. The vortex 30 has an axis of rotation running obliquely or para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com