Alcoholic beverage enriched with 1H216O

A technology of 1H216O and alcoholic beverages, which is applied in the production of alcoholic beverages, in the field of alcoholic beverages where water is rich in 1H216O by weight, and can solve the problem that the water of chemical reagents has no effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0116] This example demonstrates a method for producing high purity light water of the present invention.

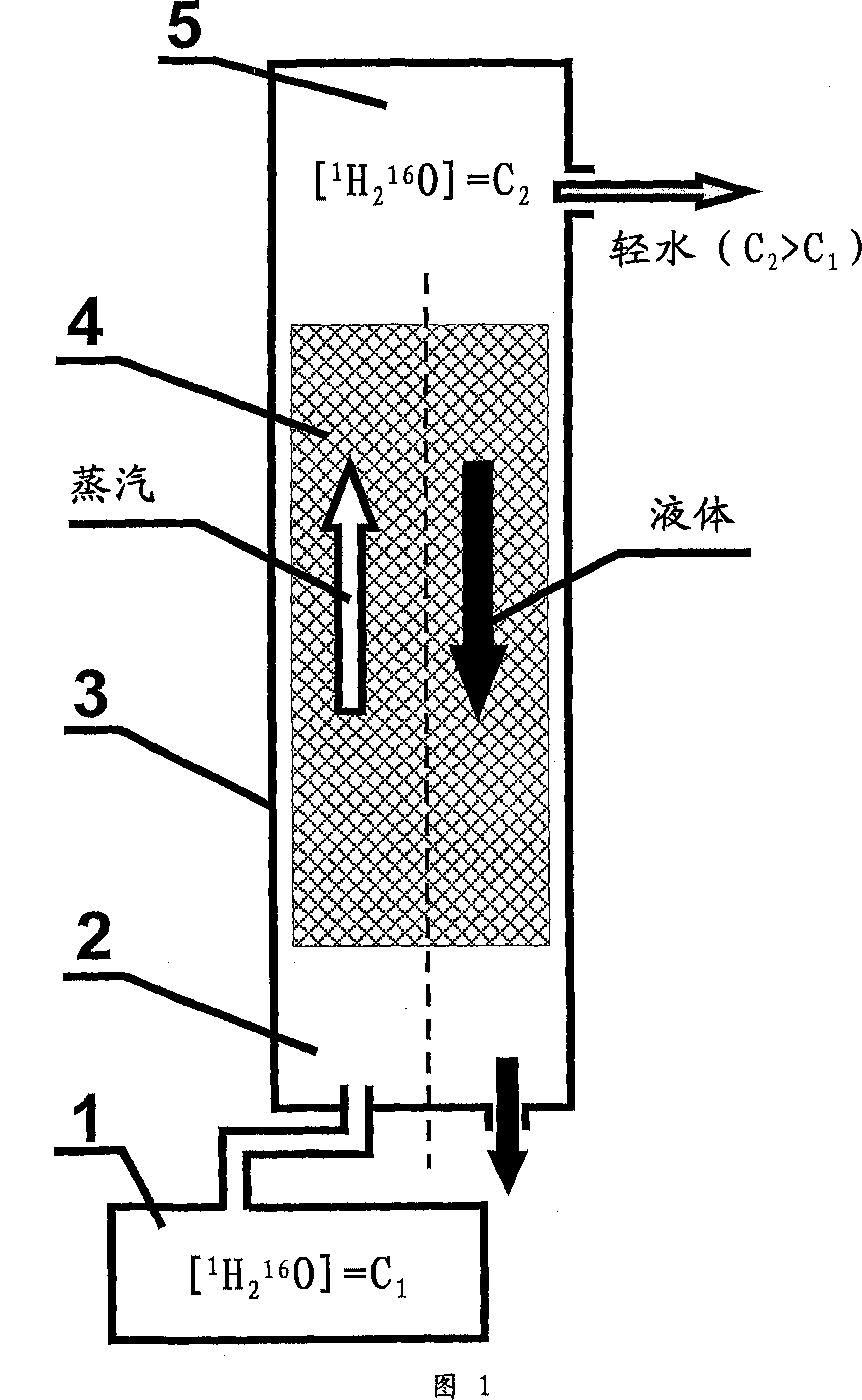

[0117] Molecules containing 99.70% light isotopes were distilled at a temperature of 60 °C and a pressure of 0.2 bar using the apparatus in Figure 1 1 h 2 16 O's natural water, prepared to contain 99.99% light isotope molecules 1 h 2 16 O light water. The distillation method includes:

[0118] -Contains 99.70% [C 1 ] light isotope molecule 1 h 2 16 O's natural water to generate water vapor;

[0119] - supplying the resulting water vapor to the bottom (2) of the rectification column (3);

[0120] - mainly on the surface of the contacting device (4) (such as structured packing or random packing) in the rectification column, the gas-liquid contact is carried out between the descending liquid and the ascending vapor; simultaneously on the surface of the entire contacting device, The liquid and vapor streams flow in opposite directions along the main flow, ie the ...

Embodiment 2

[0124] This example demonstrates the reduction of ethanol hepatitis.

[0125] Material : use rich 1 h 2 16 O water, its 1 h 2 16 O content = 99.78%. Using typical water as a control, its 1 h 2 16 O content = 99.74%.

[0126] process : An in vitro assay for the analysis of ethanol-induced hepatotoxicity as described by Neuman MG et al., Biochem. Biophys. Res. Commun. 1993. 197(2): pp. 932-41. In short, in the rich 1 h 2 16 Human hepatoma HepG2 cells were grown in the presence of 75 mM ethanol for 24 hours in the medium prepared with O water or control water. Cell viability was analyzed in the MTT test. The data are shown in Table 1 as mean ± standard deviation (n=6) of the fold increase of the control as cell viability.

[0127] Table 1. Rich in 1 h 2 16 The Effect of O Water on Alcoholic Hepatotoxicity

[0128] deal with

Cell viability, in fold increase of control

control water

1.00±1.76

High-purity light water (99.78% ligh...

Embodiment 3

[0132] This example demonstrates the use for the production of rich 1 h 2 16 O's method of vodka.

[0133] Element:

wt%

rich in 1 h 2 16 O drinking high-purity light water, wherein,

1 h 2 16 O content is 99.85wt% of water

65

Ethanol, 96%

35

light vodka

100

[0134] Under the following conditions, namely 1 h 2 16 O Typical water with a minimum content of 99.731% amounts to about 4% of the total amount of water added to alcoholic beverages, and 1 h 2 16 The final content of O is not less than 99.845%.

[0135] Rich in high-purity light water in hydroalcoholic compositions 1 h 2 16 O's vodka has reduced the toxicity of ethanol and thus has better consumption properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com