Vibration mirror motor

A galvanometer motor and rotor technology, applied in electromechanical devices, electrical components, electric components, etc., can solve problems such as limiting response speed, affecting running accuracy, low axial stiffness, etc., to eliminate drift, achieve positioning, and improve performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

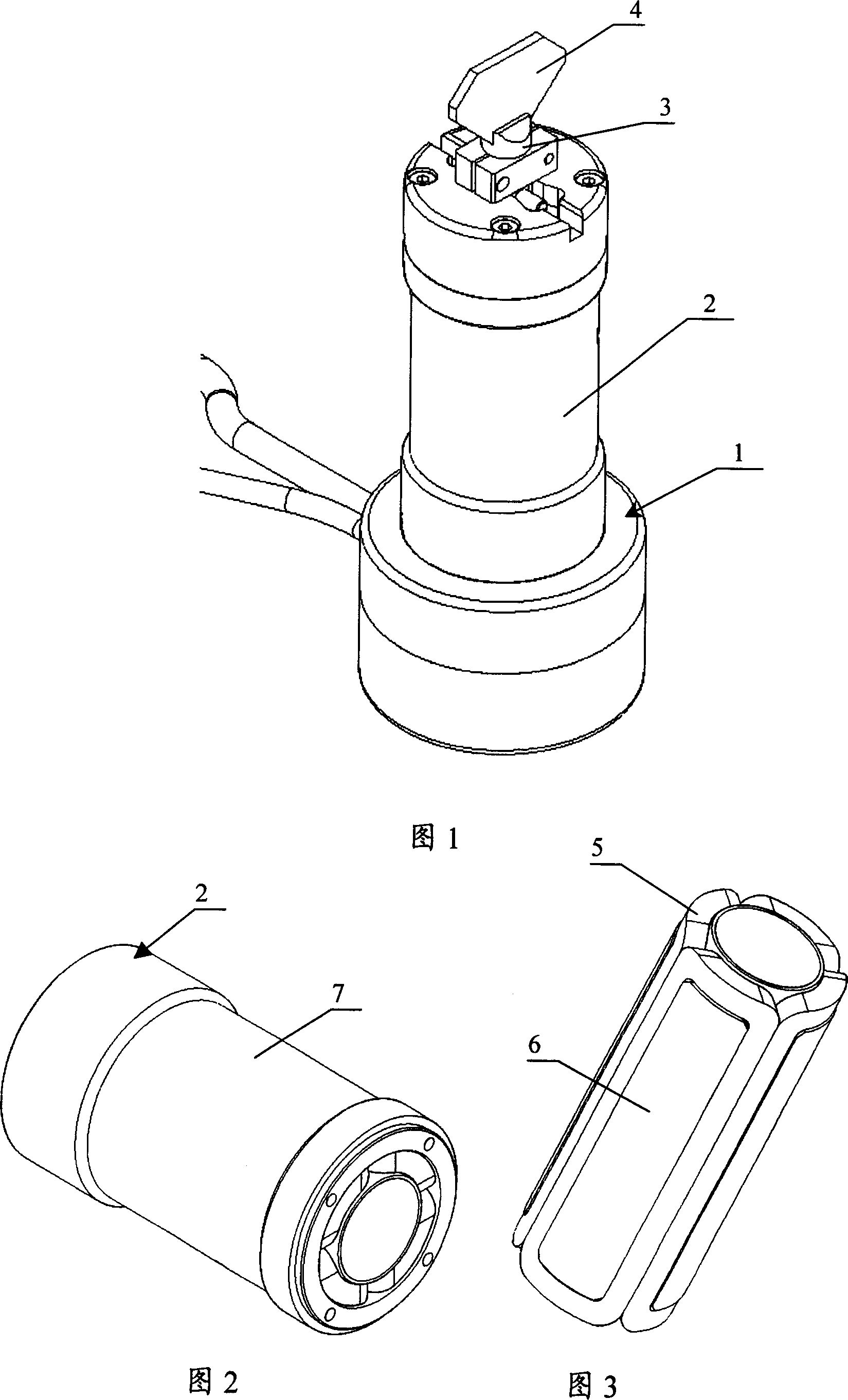

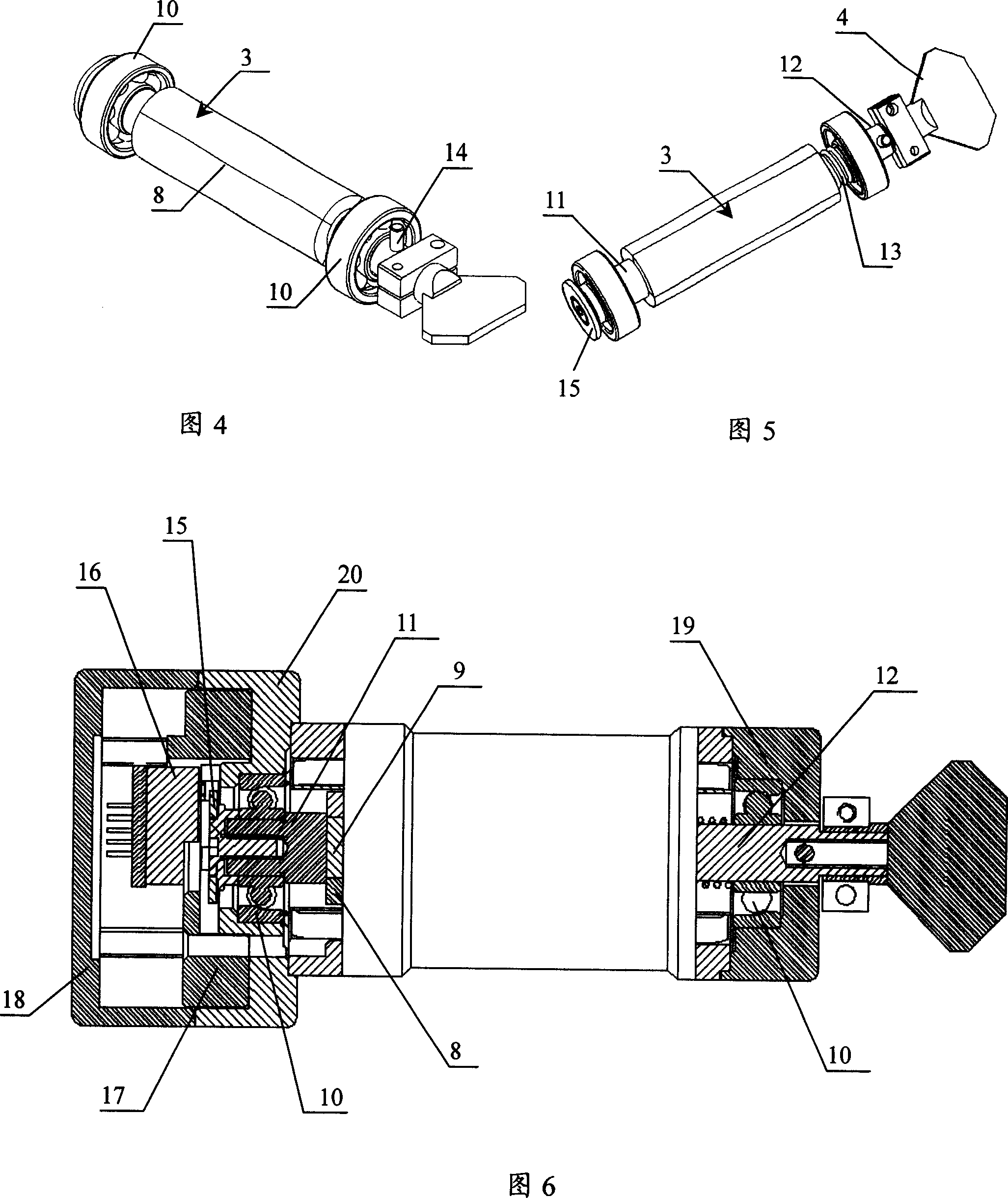

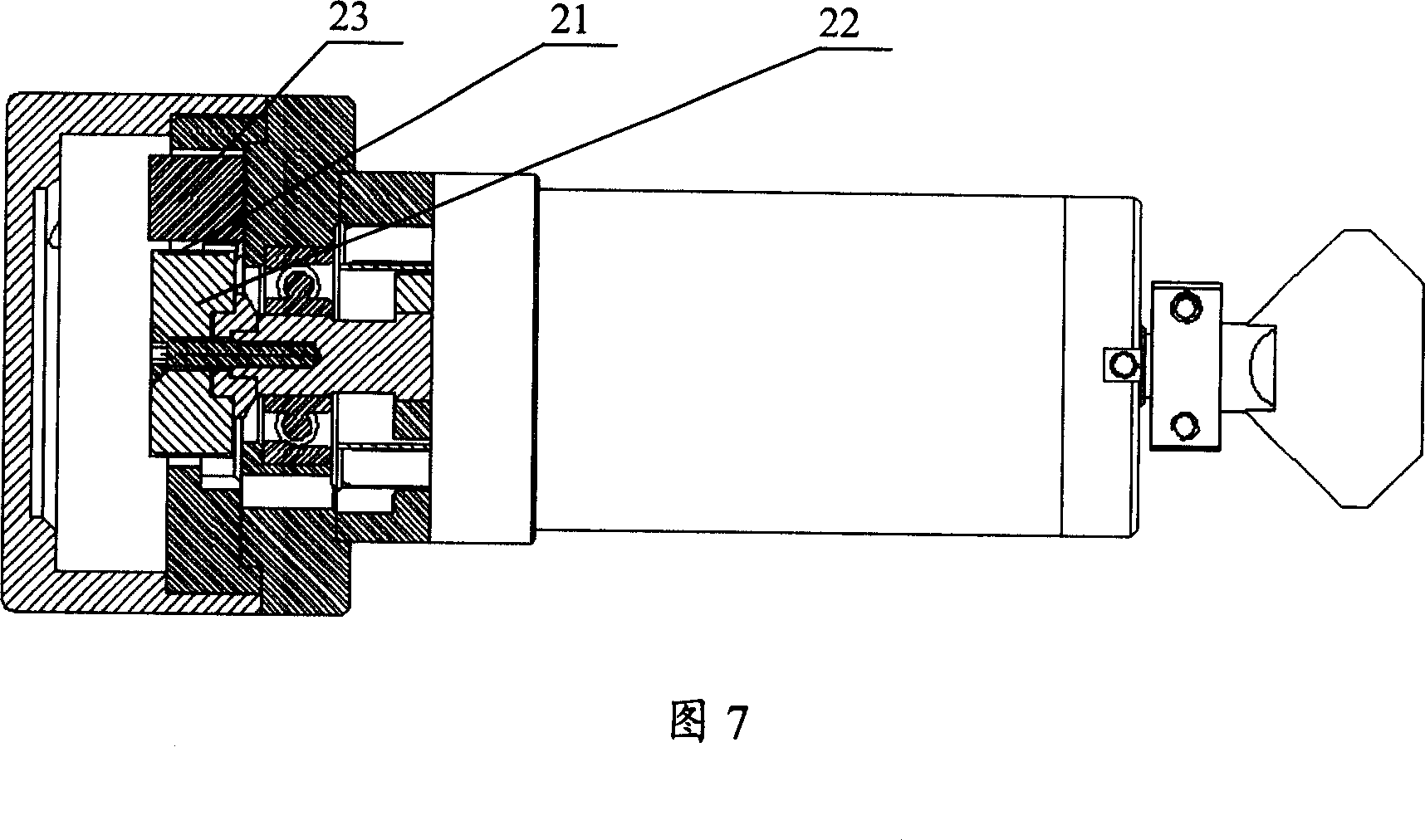

[0023] As shown in FIGS. 1 to 6, the galvanometer motor 1 of the present invention includes a stationary stator 2 and a rotor 3 that rotates relative to the stator 2. Among them, the stator 2 includes a coil 5, a frame 6 and a yoke 7. The frame 6 is made of non-magnetic material with long slots spaced apart. The coil 5 is reshaped and placed in the long slots of the frame 6 and connected in a certain order. For the multi-pole winding, the coil 5 and the skeleton 6 are vacuum casted into the yoke 7 by epoxy resin. The rotor 3 includes a magnet 8, a rotating shaft 9 and a bearing 10. A plurality of magnets 8 with alternating polarities are pasted on the magnetic rotating shaft 9 to form a multi-pole rotor. The magnetic rotating shaft 9 includes a main shaft (not shown) covered by the magnet 8, which is High magnetic permeability material, both ends are connected to the non-magnetic shaft extensions 11 and 12 respectively. The bearing 10 is an angular contact ball bearing and is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com