High conductance cryopump for type iii gas pumping

A cryogenic pump, gas technology, applied in the direction of pump, pump test, multi-stage pump, etc., can solve the problem of increasing the speed of suction of non-condensable gas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A description of the preferred embodiments of the invention follows:

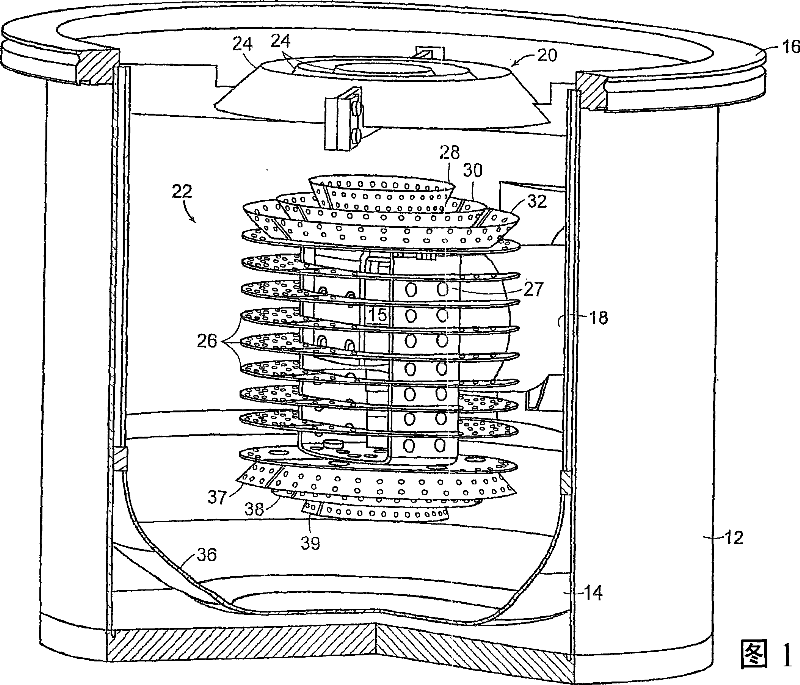

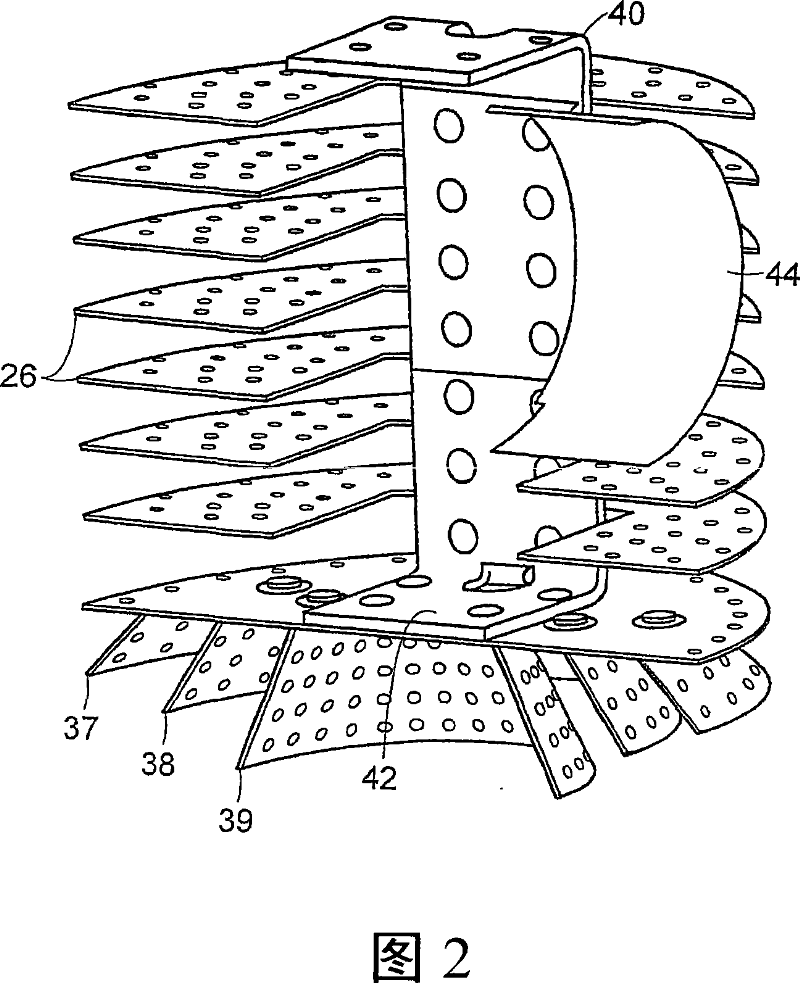

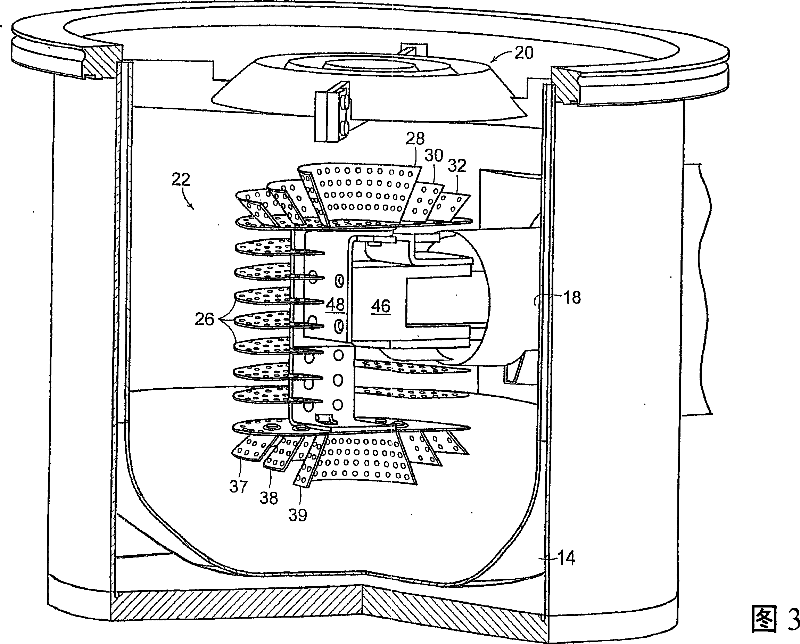

[0030] Figures 1-5 illustrate one embodiment of the present invention. Figure 1 is a perspective view of a cryopump with vacuum vessel 12 and radiation shield 14 opened. The vacuum vessel 12 may be mounted directly to the working chamber on the flange 16, or to an intermediate gate valve between the vacuum vessel and the working chamber. The cryocooler 15 of the two-stage cold finger protrudes into the housing through a side opening. In this embodiment, the second stage of the refrigerator is surrounded by a cylinder 18, wherein the cylinder 18 shields the second stage of the refrigerator. The cylinder 18 minimizes the evaporation and subsequent condensation of the gas in the cold finger, where the temperature of the cold finger fluctuates along the cold finger, as described in U.S. Patent No. 5,156,007, which Incorporated herein by reference.

[0031] The refrigerator includes a displacer in an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com