Direct-reading instrument full-automatic verification method and device thereof

A technology of direct-reading instruments and verification devices, applied in the field of measuring instruments, can solve the problems of inability to achieve automatic verification, reducing system reliability, increasing device operation and maintenance workload, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

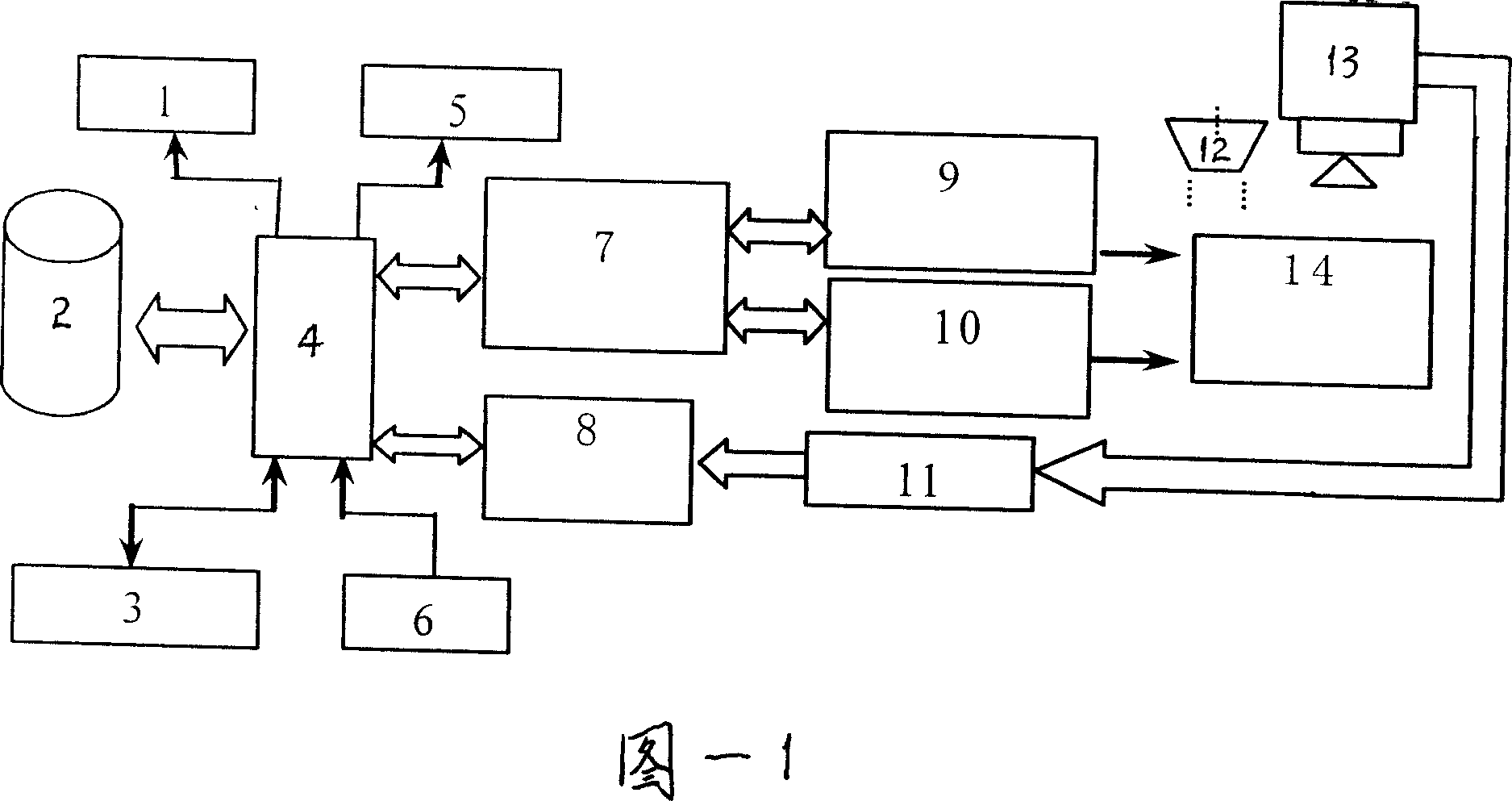

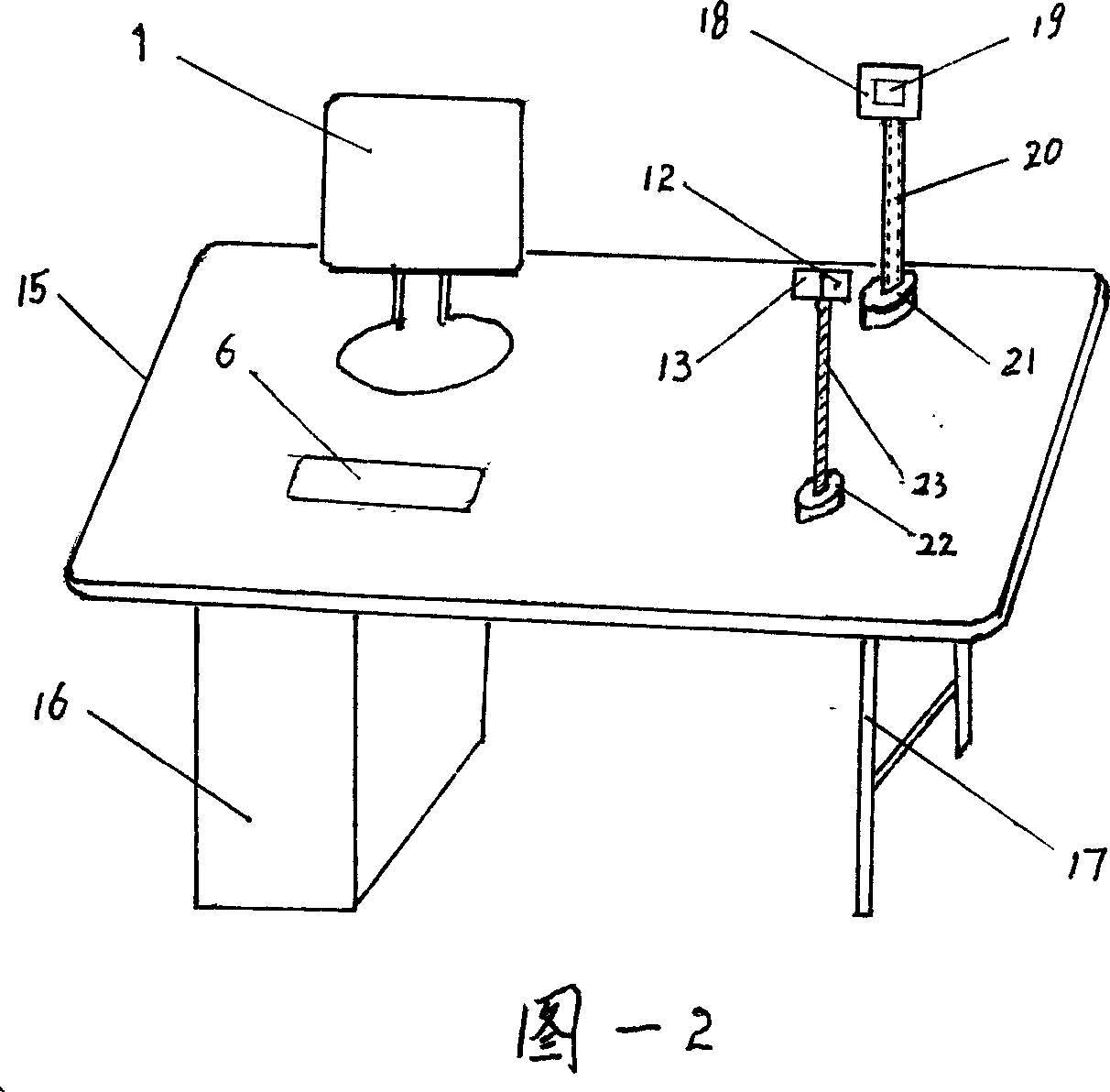

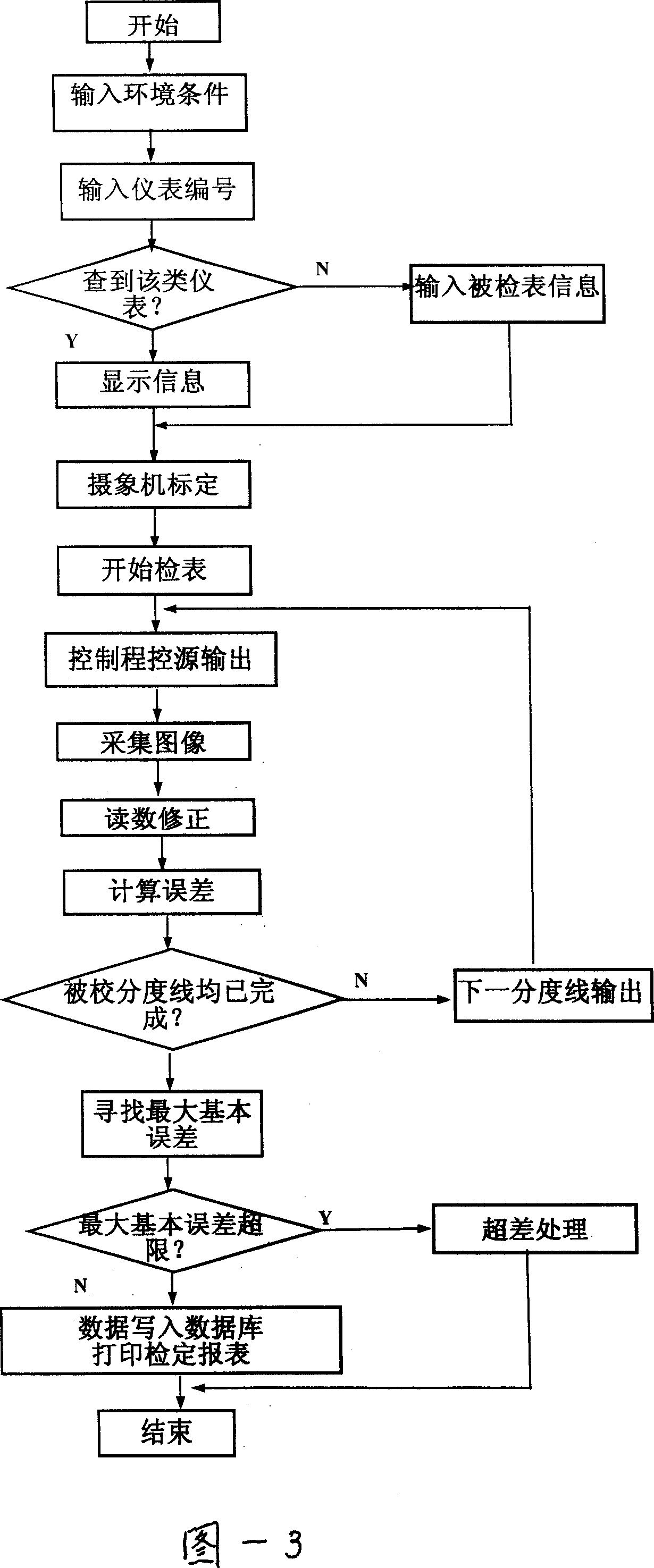

[0009] The following is a further description of the steps of the direct-reading meter automatic verification method in conjunction with Figure-1 and Figure-3. This method and device uses the computer (4) as the verification control center of the verification device. The first step in the verification of the meter is to ask the computer Enter the type of the instrument being verified, and the computer will query the relevant information of the instrument being verified from the database according to the instrument type. The second step is to adjust the positions of the camera (13) and the instrument to be verified, collect images of the standard template (19), and calibrate the internal and external parameters of the camera. The third step, start to check the meter, control the measurement standard current source (9), standard voltage source (10) to output the standard electric quantity, the size is consistent with the specific graduation line of the tested instrument, and the tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com