Asynchronous motor for oil field welldrilling

An asynchronous motor and oil field drilling technology, which is applied to asynchronous induction motors, manufacturing motor generators, electric components, etc. Improve, support the level of research and development, and improve the effect of varieties and specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

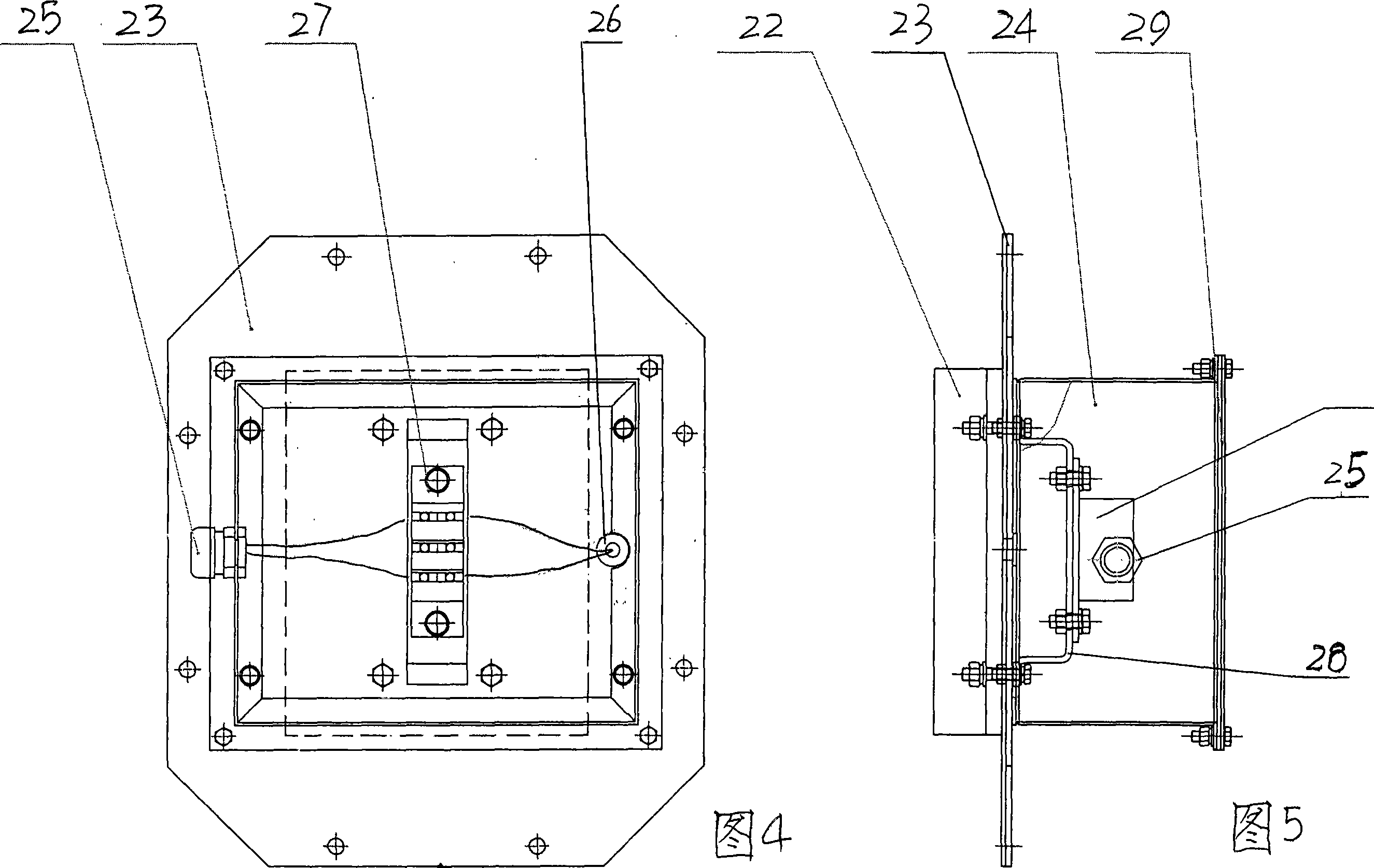

Image

Examples

Embodiment Construction

[0017] An asynchronous motor for oil field drilling, including a centrifugal fan 1 and a fan filter fixed on the top of the machine base, a junction box 2 fixed on both sides of the machine base and a heater 3 fixed on the bottom of the machine base; the fan filter includes a hexahedron A frame 4, one end face of the frame 4 is fixed with a mounting plate 6 with a fan connection port 5 on it, and at least one end face of the remaining end faces of the frame is covered with a filter layer, and the filter layer is fixed to the frame at both ends and arranged at intervals along the end face The filter grid is covered on the filter grid and is composed of a filter screen 7 fixed to the frame around it. Each filter grid is composed of a long filter sheet 8 and a short filter sheet 9 fixed to each other. The upper ends of the long and short filter sheets are bent downward. And the arrangement positions of adjacent filter gratings are staggered with each other. During concrete implem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com