Core rod support roller height measuring rule and measuring method thereof

A technology of mandrel support and height measurement, which is applied in the direction of measuring devices, mechanical measuring devices, instruments, etc., can solve the problems of difficulty in measuring the height of mandrel support rollers, poor accuracy, arm injuries, etc., and reduce the possibility of burn accidents , Improve product quality and save mandrel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The mandrel support roller height measuring ruler of the present invention and the use process of the measuring method thereof will be described in conjunction with the accompanying drawings and embodiments.

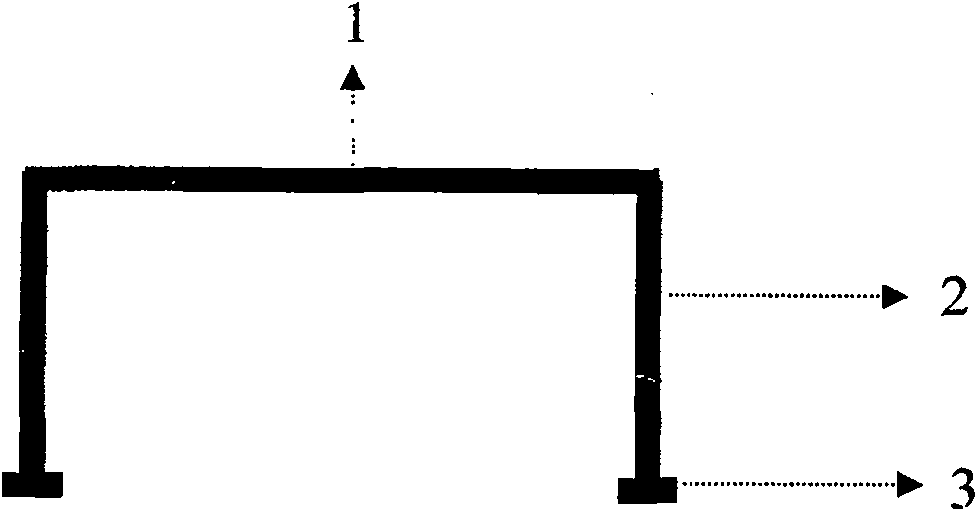

[0023] Such as figure 1 As shown, the structure of the mandrel support roller height measuring ruler is composed of a measuring ruler beam 1, and a measuring ruler column 2 is respectively connected to the two ends of the measuring ruler beam 1 to form a steel "U"-shaped frame. The end of 2 is provided with measuring ruler base 3.

[0024] Such as figure 2 As shown, instead of measuring the height H of the mandrel support roller from the bottom, it is to measure the height H of the mandrel support roller from the top. According to the principle that the height of the rolling center line is constant, the originally designed rolling center line coincides with the mandrel center line, and the method for measuring the height of the mandrel support roller by the abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com