Synchronous operation control system of roving frame driving mechanism

A transmission mechanism and synchronous operation technology, which is applied to spinning machines, continuous winding spinning machines, textiles and papermaking, etc., can solve the problem of unsatisfactory synchronous operation of the transmission mechanism of the roving frame, complicated control circuits, poor operation stability, etc. problems, to achieve the effect of improving synchronous operation performance, stable and accurate control process, stable and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

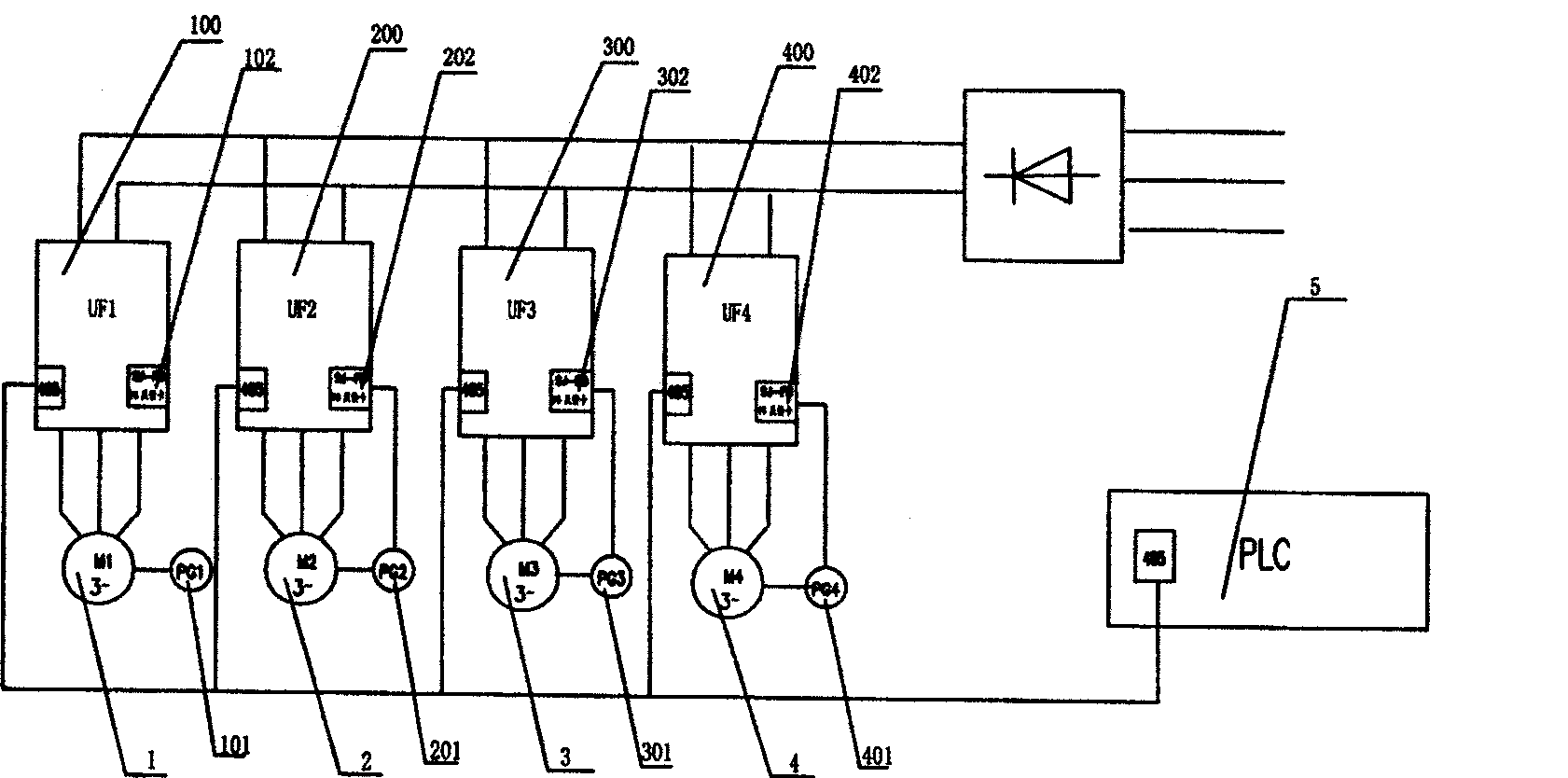

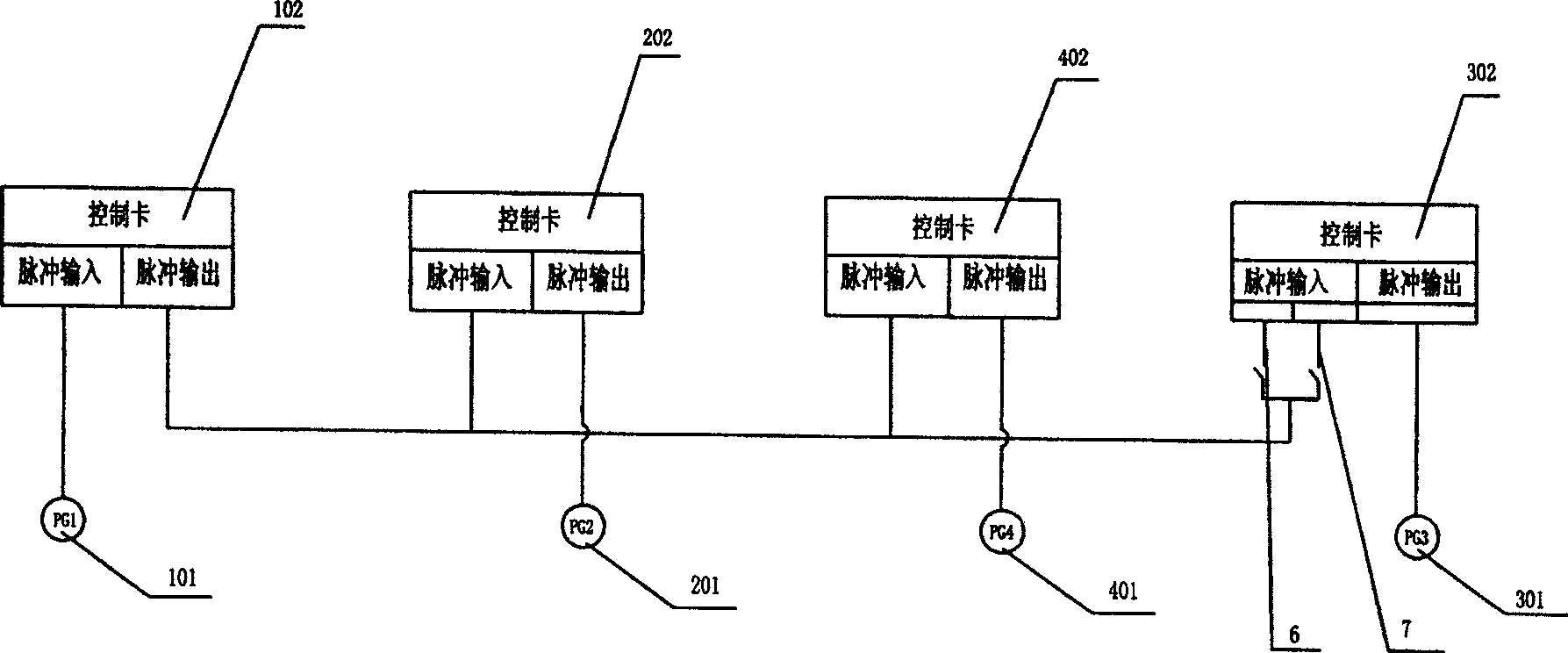

[0014] combined reference figure 1 , figure 2 , a synchronous operation control system of a roving frame transmission mechanism, in the transmission mechanism, the flyer rotating motor 1 is used as the main motor, and the bobbin winding motor 2, the tendon lifting motor 3 and the roller drafting motor 4 are all used as the slave motors. The frequency converter 100 configured with the main motor 1 is used as the main frequency converter, the frequency converter 200 configured with the bobbin winding motor 2, the frequency converter 300 configured with the tendon lifting motor 3 and the frequency converter 400 configured with the roller drafting motor 4 are all used as slave frequency converters device. The above-mentioned master-slave motors are all equipped with encoders for real-time detection of the motor speed and outputting corresponding pulse signals, wherein the encoder 101 configured by the master motor 1 is used as the master encoder, and the encoder 201 configured b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com